2021 is going to be a great year. As the world winds down pandemic restrictions and learns to operate safely, there is a lot of new demand, backlogged projects, and catch-up maintenance to do. The ISM Purchasing Managers Index (PMI) keeps rising, reaching 64.7 in March 2021. We here at Precision Digital think we are going to have a great year. So… what do you plan to do about it?

For those end users who trust Precision Digital products, now is the time to get your plant back in proper order. If you see broken equipment, abandoned projects, and failed installations as you walk around your plant now is the time to contact Precision Digital, or our local distributors, to help you fix those things. If you are sick of climbing tanks, have failed attempts at using other manufacturers’ wireless solutions, or want to improve your protection against cyber attacks with local redundant controllers, now is the time to do it.

To our distributors, I say now is the time to have final training sessions on new products, and then get out in the field. Precision Digital’s sales team will be on the road in May, so we are happy to support you, especially as you go to water and wastewater facilities to promote our new Water and Wastewater Instrumentation Solutions Guide. It would be great to join you for joint calls to your major water and waste accounts, so reach out and let’s plan a visit together.

As you will see from this Indicator, there is a lot going on at Precision Digital. We think it is going to be a great year. I suggest you all consider what you need to do to make sure you are ready for what’s ahead in 2021 by preparing now. Please feel free to contact us and let us know how we can help.

Watch this video presented by Owen Peters, Regional Field Sales Manager at Precision Digital, who describes how the PDW90 point to multipoint 900 MHz Industrial Wireless System was installed in a wastewater treatment plant in the northeast US. See how this industrial wireless system brings 8 signals from various locations around the plant back to a base station located in the central control room.

A large food & beverage company had a wastewater treatment facility that processed over a million gallons of effluent per day. The plant had 4 flow and 4 analytical measurement signals that needed to get back to the control room.

The measurements were scattered all over the plant. Running conduit and wires all the way back to the control room was undesired from a labor and cost standpoint. They wanted a wireless solution but wanted to make sure that the wireless signals could reliably get back from each measurement point to the control room.

Read the application note to find out how this water treatment facility found an economical solution to transmit their 4-20 mA and Modbus signals.

The PD460/461 valve positioners provide a convenient way to generate a 4-20 mA signal that can be used to control another device. The PD460/461 valve positioners feature a backlit LCD and are programmed to display a value of 0-100% relating to the 4-20 mA output.

A built-in dial is provided to vary the displayed / output value. The dial may be programmed for coarse or fine adjustment. The valve positioners are available as panel mount (PD460) or NEMA 4X (PD461) versions.

In addition, NEMA 4X enclosures are available to house up to three of the panel mount versions. Decals are provided for %, mA, Open, and Closed for the user to apply to the faceplate. TherRedundancy in control systems is crucial to ensure a plant is not completely vulnerable to cyber attacks. For instance, if a control system is compromised, then a local 4-20 mA indicator can serve as a backup local monitoring, control and alarming system.

According to the Associated Press, on February 5th, 2021, a hacker remotely accessed the control system at a water treatment plant in Florida and altered chemical levels. The hacker attempted to increase the amount of lye used to treat the water to dangerous levels. Even though the intrusion was caught and stopped by the operator on site quickly, the incident exposes how vulnerable both industrial and municipal plants can be to cyber attacks.

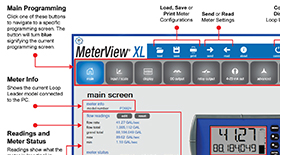

It is now easier than ever to program Loop Leader series meters and rate/totalizers. The newly released MeterView XL software manuals include complete download instructions, descriptions, and detailed screenshots of each programming window. See how convenient it is to program all the powerful features of the Loop Leader including inputs and outputs, relays, open collectors, and more. Learn how to set up your display parameters and other advanced settings quickly without having to use the buttons on the front of the panel meter.

There is a manual for each version of the Loop Leader available for download at predig.com; LIM6602MVXL for PD6600 series process meters, LIM6603MVXL for PD6603/07 Feet & Inches level meters, and LIM6622MVXL for PD6620 Series of rate/totalizers.

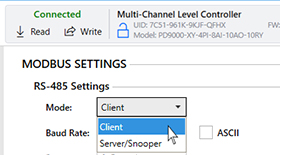

The ConsoliDator+ configuration software is intuitive, and most customers can get their PD9000 controller programmed as they like without even looking in the manual. With the new and improved software version 2.1.2, programming your Modbus network has never been easier. It includes a Modbus settings screen that allows for easy setup of the client, snooper, or spoofer modes and parameters for the baud rate, parity, and Tx delay and Rx timeout. Additionally in the Modbus settings screen, a passcode can be entered for the server settings.

A sugar mill had two large molasses tanks that were used to fill railcars at their loadout facility. The railcars ranged in size from 20,000 to 25,000 gallons. They needed to maximize the fill of each railcar but leave space at the top to ensure that there were no spills. The sugar mill had experienced molasses spills when filling their railcars. These molasses spills were very expensive in terms of the cleanup and downtime in using their loadout facility. They needed an overfill prevention system to avoid spills and to safely optimize the filling of their railcars. Read more to find out how this sugar mill solved the problem!

|

If you do, you’ll want to watch this RECORDED WEBINAR on the new Modbus capabilities of our ConsoliDator+ Multi-Channel Controller.

These capabilities include the ability to:

- Display up to 160 Modbus registers on a full-color QVGA screen with NO complicated PLC programming!

- Generate up to 35 4-20 mA outputs or 30 relay outputs.

- Perform a variety of math functions.

The ConsoliDator+ can operate in any of these modes:

- Client: In Client (or Master) mode, read multiple variables from your sensors and maximize their potential.

- Snooper: With packet sniffer functionality (Snooper), listen and read PVs on RS-485 bus

- Spoofer: Assign multiple addresses and customized register numbers

Never heard of a Modbus Spoofer? Watch this recorded webinar to learn how this feature can help you replace existing Modbus servers without changing the Client configuration.

- New PD4 Large Display Loop-Powered Meter

- Data Logging for the ConsoliDator+

- New SuperNova PID Controllers