The 4-20 mA level transmitter is connected to the analog input of the secondary unit and then transmitted to the primary unit. The primary unit is connected to the PD6602 display. Relay 1 on the PD6602 connects to digital input 1 of the primary unit and transmits the signal to digital output 1 on the secondary unit which triggers the high alarm. A Loss of Signal (LoS) digital output is connected to the PLC which sends an alert message if the wireless signal is lost.

The level in each tank is measured by a 4-20 mA level transmitter that is connected to a PDW90 field unit. The four signals are then wirelessly transmitted to the PDW90 base station. The base station then sends all four signals out as 4-20 mA signals to the ConsoliDator+ multivariable controller.

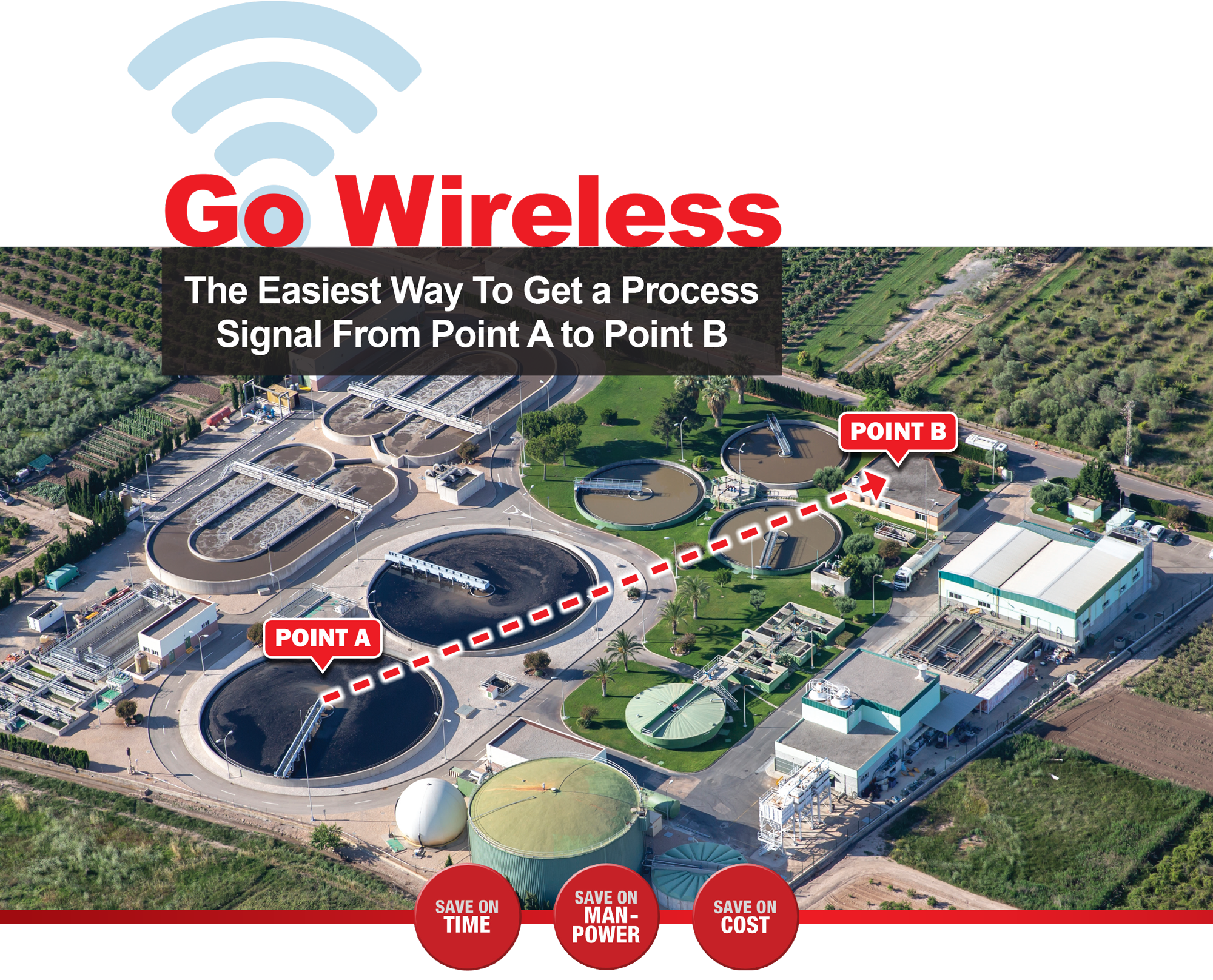

Many times a plant manager just wants to add a few measurements in the field and bring them back to the control room at the lowest cost; and the simplest way is to do it wirelessly. The following examples show how PDW wireless products were used for transmitting process information to where the operator wants it.

Municipal Wastewater Plant Uses PDW90 Wireless System to Transmit Process Signals to SCADA System

The Problem:

The operator of this municipal wastewater plant needed to monitor the process information from around the facility on a SCADA system located in the control room of the central building.

The process information comes from (2) 4-20 mA transmitters and (6) digital status signals scattered around the plant that are a good distance away from the central building ![]() including a chemical storage tank

including a chemical storage tank ![]() , open channel flow

, open channel flow ![]() , aeration building blower status

, aeration building blower status ![]() , pump station pump status

, pump station pump status ![]() , and compost blower status

, and compost blower status ![]()

![]()

![]()

![]() .

.

Hard wiring all these transmitters would mean running hundreds of feet of physical wires throughout the plant which would be too costly for the budget and take too much time, something the plant manager did not want to do.

The Solution:

With future expansion in mind, the solution was to install a PDW90 point to multi-point wireless system consisting of one PDW90 base station and eight PDW90 field units. The field units were easy to install right out of the box, and with the 24 V power available around the plant, made it even more convenient to get the units up and running in no time!

To make sure there was a good connection between the base station and the field units a PDA10 wireless survey tool kit was used, which allowed the installer to test the signal before installing the units.

PDW90 Field Unit Installation at Storage Building

PDW90 Field Unit Installation at Open Channel Flow

PDW90 Field Unit Installation at Aeration Basin Blowers

The rugged field units were mounted directly at the transmitter sites, each being independently ranged to the base station.

The range of the PDW90 units are 1 mile line-of-sight outdoors and 500 feet indoors. Although, many of the field units had obstructions to the base station, the antennas were mounted up high to avoid most obsticles and all signals between the units and base station were succesful.

PDW90 field units with NEMA 4X, IP68 aluminum enclosures were used at this plant, but the field units also come in stainless steel which are even more resistant around salt water or in harsh chemical environments like this wastewater plant. The enclosures contain plenty of room for field wiring connections and an optional two Form A (SPST) relays module.

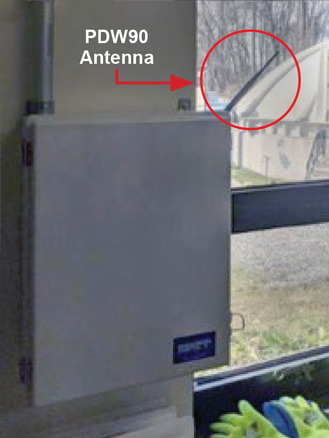

PDW90 Base Station with Attached Antenna Inside Building

4-20 mA and Digital I/O go to the SCADA system

The PDW90 base station was installed indoors in the central building. Initially, the installers were going to run a conduit outside the building to connect the antenna to a remote location, but near the window they had good enough signal strength from inside the building even though there was not a line of sight to any of the field units.

Finally, the installer connected the (2) 4-20 mA and (6) digital outputs from the PDW90 into the SCADA system that displays all the information.

Wastewater Treatment Facility Uses PDW90 Wireless System to Transmit Process Signals for Primary Flow Calculation and Auto Sampling

System Overview

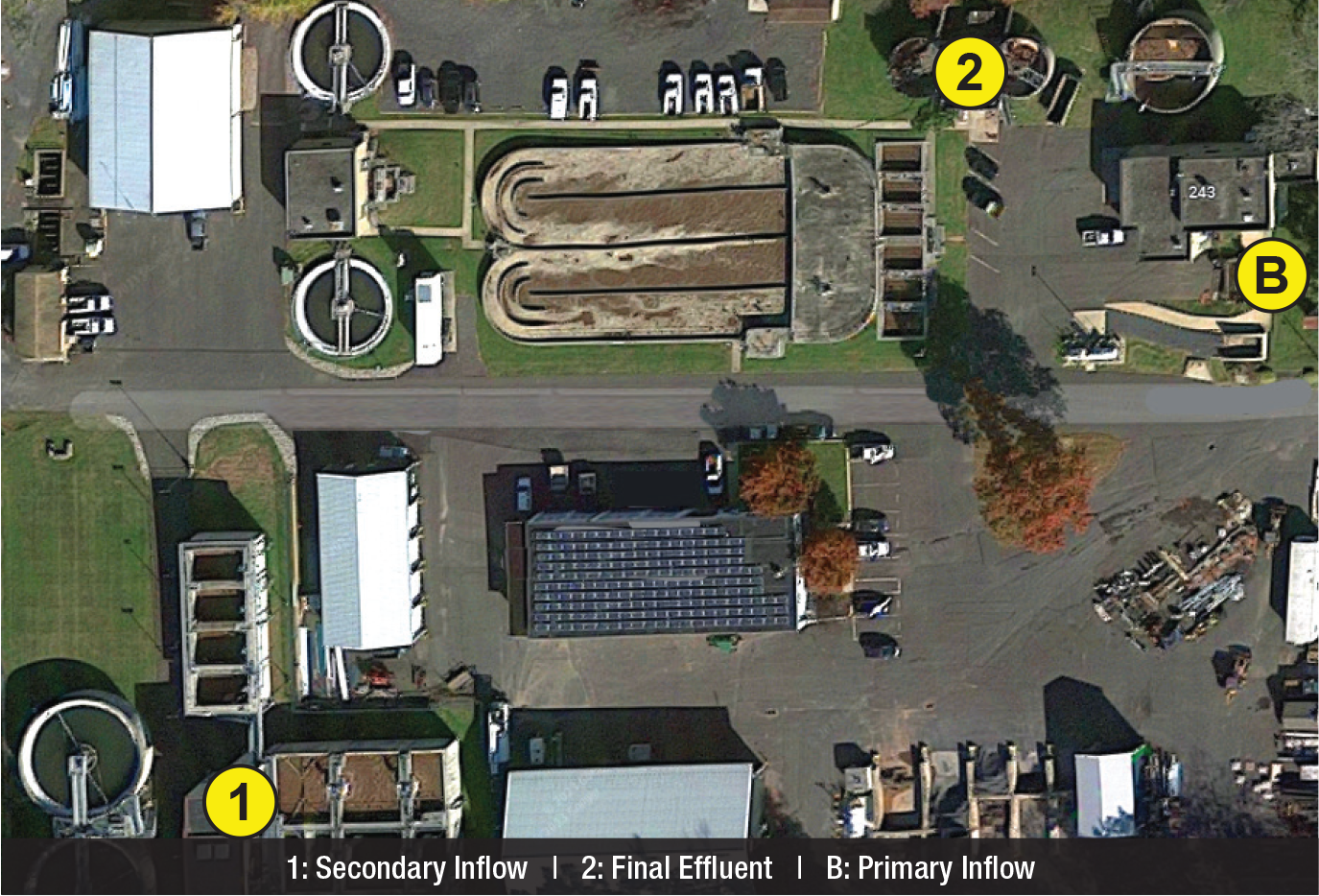

Process signals from the Secondary Inflow

PDW90-FN Connected to 4-20 mA Sensor Inside the Building

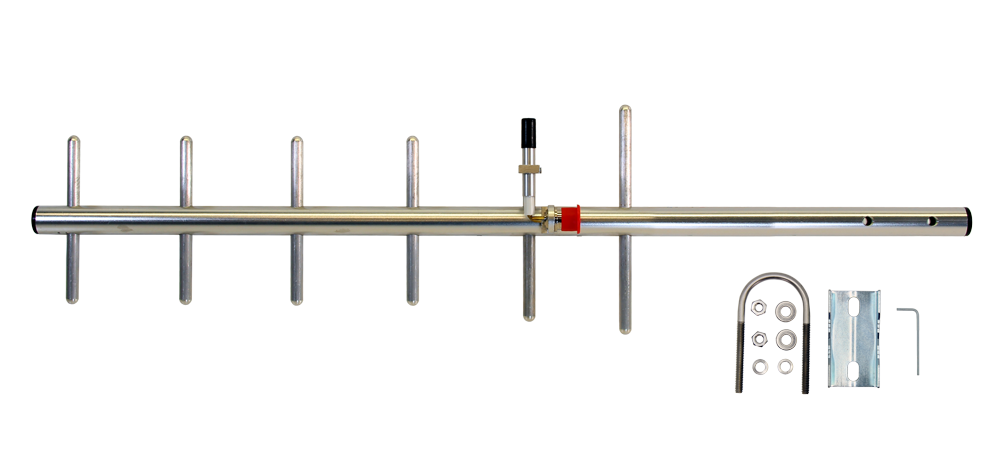

PDA3900 Yagi Antenna Mounted Outside the Building

Location 1: Secondary Inflow

An existing 4-20 mA sensor from the Secondary Influent is wired to a PDW90-FN field unit inside the building. Coax cable is run through the wall to a Yagi antenna mounted outside. The signal path is 500' and goes through the trees.

PDW90-FN Connected to 4-20 mA Sensor Inside the Building

PDA3900 Yagi Antenna Mounted Outside the Building

Location 2: Final Effluent

The 4-20 mA sensor from the Final Effluent is connected to a PDW90-FN field unit inside the building.

Coax cable is run through the wall to the antenna mounted on the roof. The signal path is 150' and goes through another building.

Yagi Antenna connected to the PDW90 Base Station

PDW90 Base Station, ConsoliDator+ Controller, and Auto-Sampler

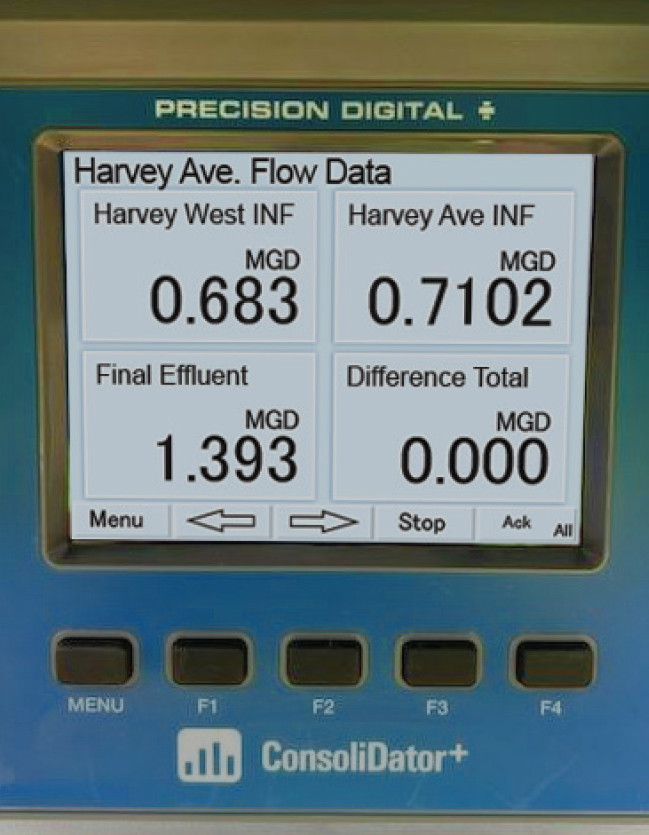

PD9000 ConsoliDator+ Multivariable Controller Display

Location B: Primary Effluent

The base station antenna receives signals from locations ![]() &

& ![]() , then sends 4-20 mA signals to the PD9000 multivariable controller which subtracts the Secondary Inflow from the Primary Effluent to calculate the Primary Inflow occurring at this spot.

, then sends 4-20 mA signals to the PD9000 multivariable controller which subtracts the Secondary Inflow from the Primary Effluent to calculate the Primary Inflow occurring at this spot.

The Calculated Primary Inflow value is then sent to the auto-sampler.

All the process values are logged to the included USB drive on the ConsoliDator+ Controller.

Going wireless can be a solution to many common installation problems that come up when retrofitting existing process control systems, but it can also create headaches of its own.

Many common wireless solutions on the market require that process signals be converted to ethernet protocol or make it necessary to repurchase the entire system at greater cost.

Precision Digital’s PDW industrial wireless systems are designed to hook directly into an existing process control system and transmit many common process control signals, such as 4-20 mA, discrete digital I/O, and Modbus, wirelessly from point A to point B.

Going wireless doesn’t have to break the bank, or your existing systems. With Precision Digital’s industrial wireless products you will save on time, save on manpower, and save on cost.

Precision Digital’s PDW30 is a Point-to-Point Wireless Process Signal Bridge that is virtually plug and play right out of box. It is perfect for connecting two field locations together.

It consists of a primary and secondary wireless unit which accept an analog signal (4-20 mA, 0-10 V, 0-5 V, 1-5 V), up to four discrete digital input signals, and Modbus serial communications. They can then output a 4-20 mA signal, up to four discrete digital outputs, and Modbus at the other end.

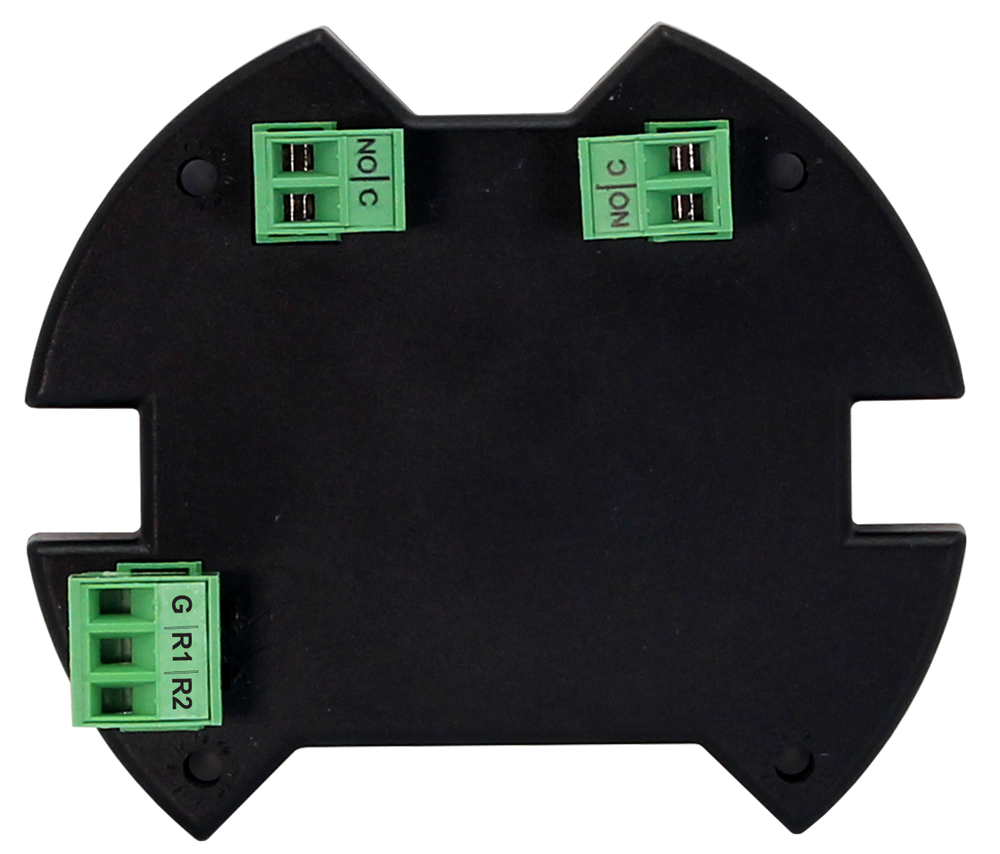

Communication between the devices is two-way, so each wireless device can input and output at the same time. To indicate alarm situations, both units can be equipped with an optional dual relays module.

PDW30 Key Features

- Signal Wire Replacement for One 4-20 mA Signal

- Virtually Plug and Play Right Out of Box

- Loss of Signal (LoS) Digital Output

- Field Installable Relay Module with Two Form A (SPST) 5A Relays (Available for Both Units)

- CapTouch Through-Glass Button Programming for Non-Advanced Settings

- IP68, NEMA 4X Aluminum & Stainless Steel Enclosures

- 9-30 VDC Power

The PDW90 Point to Multi-Point Wireless Process Signal System is a solution for more complex wireless applications where process signals from multiple field locations need to be consolidated in one central location, such as a control room or central monitoring location.

In order to be as flexible as possible, the PDW90 base station has completely enclosed, easy-to-install I/O modules including dual analog inputs, dual analog outputs, four digital I/O, and dual relay outputs. The base station also includes Modbus serial communications.

Up to 32 individual field units can be placed at different locations around a facility and connected to a single base station.

PDW90 Key Features

- Signal Wire Replacement for up to 32 4-20 mA Signals

- Plastic NEMA 4X Base Stations for 2, 6, or 16 Field Installable I/O Modules:

○ Dual Analog Input ○ Dual Analog Output

○ Dual Relay Output ○ Four Digital I/O - Field Units with IP68, NEMA 4X Aluminum & Stainless Steel Enclosures

- RS-485 Modbus

- PDW Manager Programming Software

- Loss of Signal (LoS) Digital Output

Precision Digital’s line of industrial wireless products also includes accessories to expand and customize an installation to meet the unique needs of any application.

Wireless installations may be expanded using an array of base station I/O modules, additional wireless field units, repeater units, relays option module, and high-gain antennas for longer distances.

The wireless survey tool kit can provide an accurate representation of wireless signal strength throughout your facility before performing the installation.

Precision Digital offers a stainless steel pipe mounting kit (PDWA6963-SS) that provides an convenient way to mount PDW wireless field units to horizontal or vertical 1.5" or 2" pipes.

PDW products have a signal range of 1 mile line-of-sight outdoors or 500 feet indoors. This range can be expanded using wireless repeater units or high-gain antennas.

PDW products include free PDW Manager PC software with USB connection for setup.

PDWR Key Features

- Wireless Repeater Unit Improves Signal Strength and Range for PDW Wireless Systems

- Use in PDW30 Point to Point and PDW90 Point to Multi-Point Wireless Systems

- Increase Range an Additional 1 Mile Line-of-Sight Outdoors, 500 Feet Indoors

- Use CapTouch Through-Glass Buttons to Change Network ID

- IP68, NEMA 4X Aluminum & Stainless Steel Enclosures With Plenty of Room for Field Wiring

PDWM90 Key Features

- Easy to Install

- Adds Functionality to the PDW90 Wireless System

- Three Sizes of PDW90 Base Stations Can Hold 2, 6, and 16 I/O Modules

- Modules are Completely Enclosed in Plastic Housings for Added Protection

- Dual Analog Inputs Module

- Dual Analog Outputs Module

- Four Digital I/O Module

- Dual Relays Module