Features

- CSA, ATEX and IECEx Certified Explosion-Proof Meter

- 4-20 mA, ± 10 V, TC & RTD Field Selectable Inputs

- Full 4-Digit Display, 1.20" (30.5 mm)

- CapTouch Through-Glass Button Programming

- Display Mountable at 0°, 90°, 180°, & 270°

- Isolated 24 VDC @ 200 mA Transmitter Power Supply Option (AC powered meters only)

- 2 Relays + Isolated 4-20 mA Output Option

- Free PC-Based MeterView Programming & Monitoring Software

- Sunlight Readable Display

- Operating Temperature Range: -55 to 65°C (-67 to 149°F)

- CSA Certified as Explosion-Proof / Dust-Ignition-Proof / Flame-Proof

- ATEX and IECEx Certified as Dust-Ignition-Proof / Flame-Proof

- Input Power Options: 85-265 VAC / 90-265 VDC or 12-36 VDC / 12-24 VAC

- Duplex Pump Controller with Alternation Capability

- External Contacts for Remote Button Operation

- On-Board RS-485 Serial Communications

- Modbus® RTU Communication Protocol Standard

- Copy Meter Settings to Other PD8-765 Meters

- Password Protection

- Max/Min Display

- High & Low Alarms with Multiple Reset Actions

- Flanges for Wall or Pipe Mounting

- Explosion-Proof Aluminum or Stainless Steel NEMA 4X / IP68 Enclosures

- Four 3/4" NPT Threaded Conduit Openings

- Stainless Steel Pipe Mounting Kit

- Stainless Steel Tag Available

- 3-Year Warranty

Overview

Front

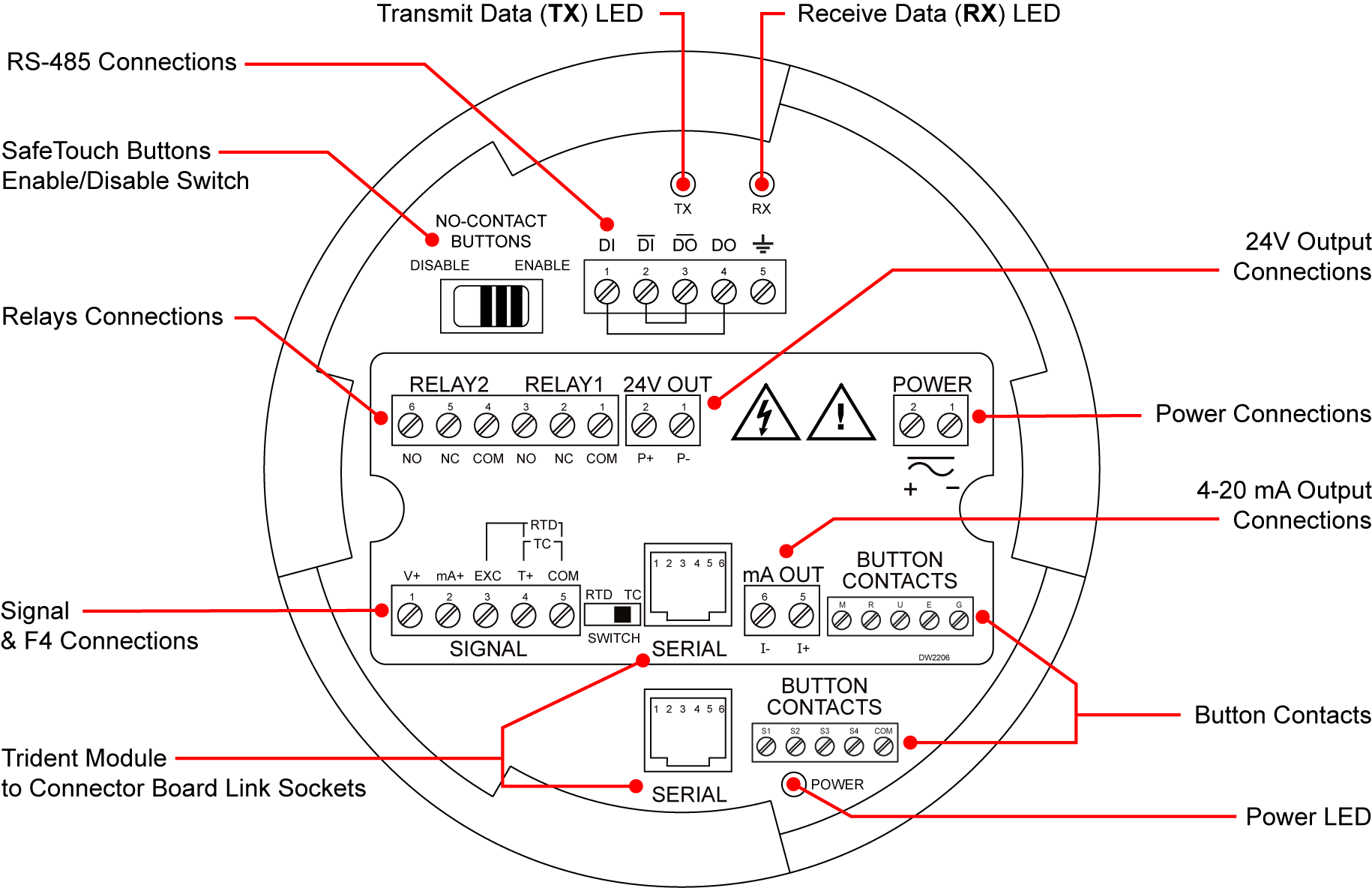

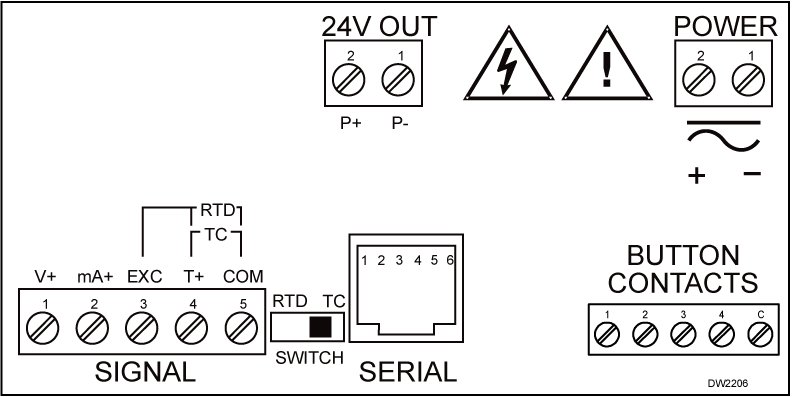

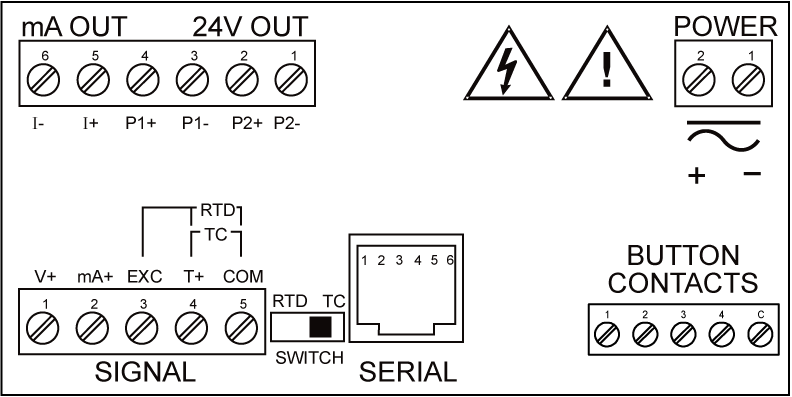

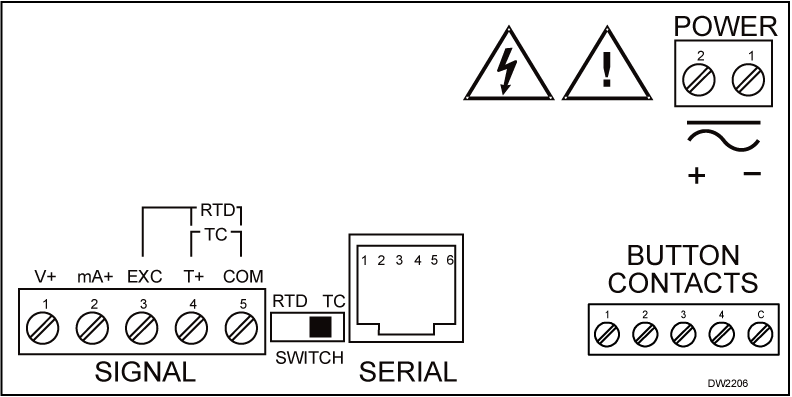

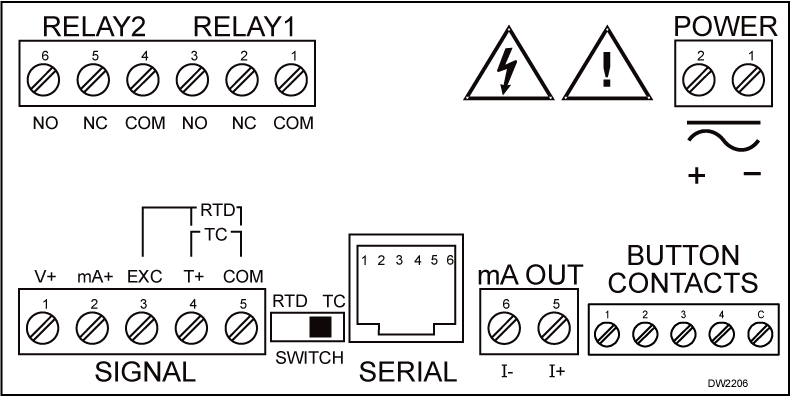

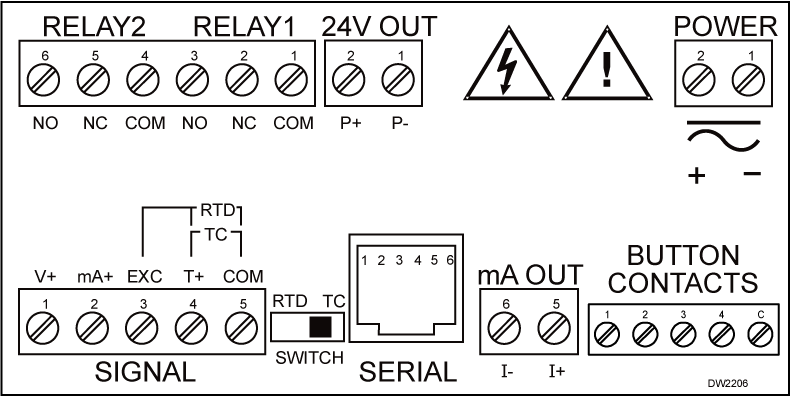

Connections

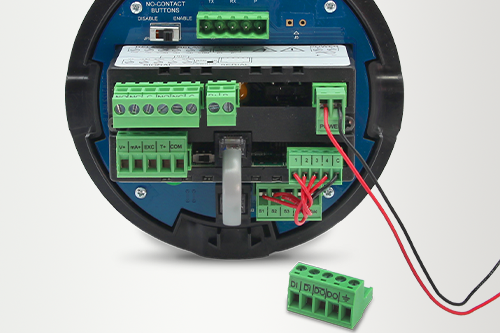

Two SPDT relays; 24 V transmitter power; TC, RTD, 4-20mA or 0-10 VDC inputs; 4-20 mA output; four external button contacts

The ProtEX-MAX PD8-765 has a 5-position terminal block for connecting RS-485 serial devices.

The Only Explosion-Proof Process & Temperature Meter You Will Ever Need

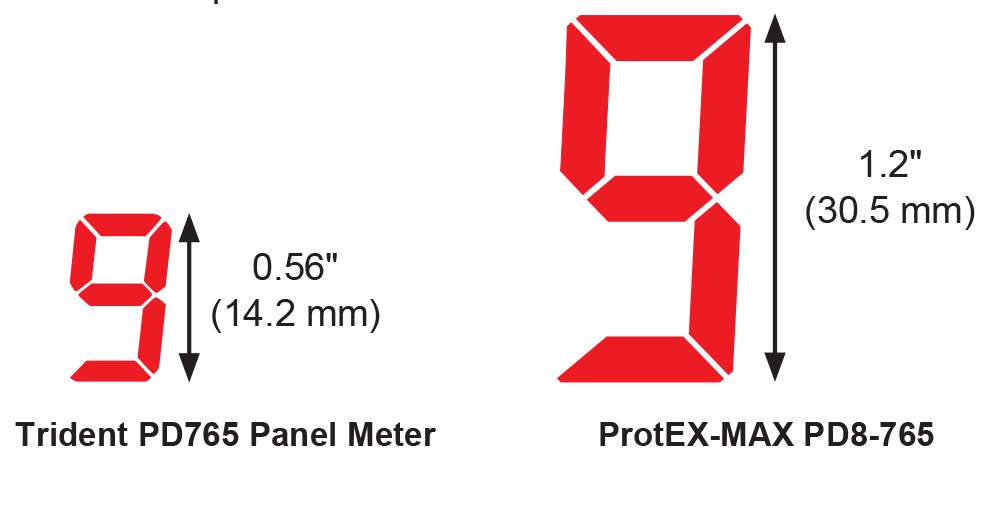

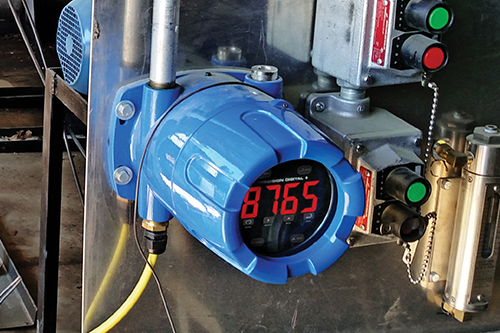

The ProtEX-MAX PD8-765 explosion-proof, large-display, process and temperature meter offers all the functionality of the PD765 Trident as a CSA, ATEX, and IECEx certified explosion-proof product. The PD8-765's huge 1.2" (30.5 mm) sunlight readable display is visible from over 30 feet away. This explosion-proof indicator can be field programmed to accept process voltage (0-5 V, 1-5 V, etc.) and current (4-20 mA) inputs, 100 Ohm RTDs, and the four most common thermocouples.

There are two power options for the ProtEX-MAX: 85 to 265 VAC or 12-36 VDC and the AC powered version can provide 24 VDC to power the transmitter if needed. Programming and setup can be performed with the four CapTouch through-glass buttons, free MeterView software, or using the Copy function.

Two relays and isolated 4-20 mA output options increase the utility of the PD8-765. The relays can be used for alarm or control applications. The 4-20 mA output provides an isolated retransmission of the input signal; especially useful for temperature inputs like thermocouples and RTDs. Now you can have an explosion-proof temperature transmitter with a huge, bright display! It is housed in an explosionproof housing with convenient mounting flanges, available in aluminum or stainless steel.

The PD8-765 ProtEX-MAX display height is an astounding 1.2" (30.5 mm). It can be read easily from distances of up to 30 feet away! The display intensity function allows the selection of eight levels of intensity for various lighting conditions, including direct sunlight.

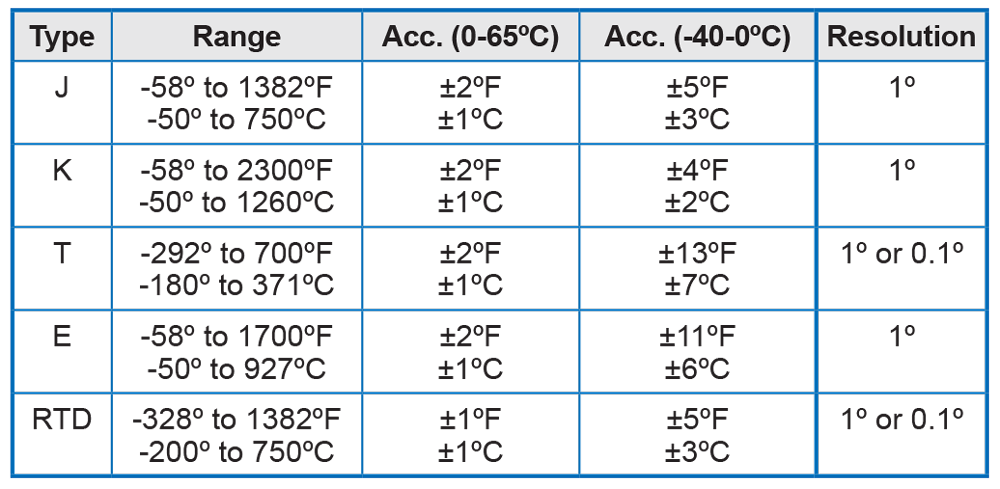

Process & Temperature Inputs

The PD8-765 is factory calibrated to accept 4-20 mA, ±10 VDC, type J, K, T, or E thermocouples and 100 Ω platinum RTDs. Process inputs can be scaled with or without applying an input for virtually any engineering units. Temperature inputs can be programmed to display in degrees Fahrenheit or Celsius and the type K thermocouple can display up to 2300ºF.

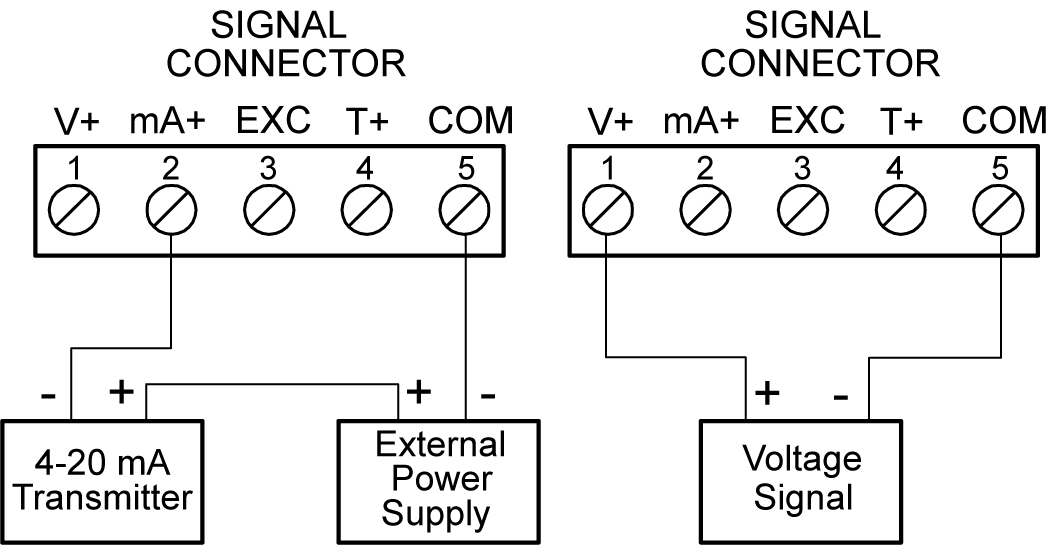

Current & Voltage Inputs

Setting up the meter to accept a current or voltage input could not be easier. All setup is performed with the front panel buttons and there are no switches or jumpers to deal with.

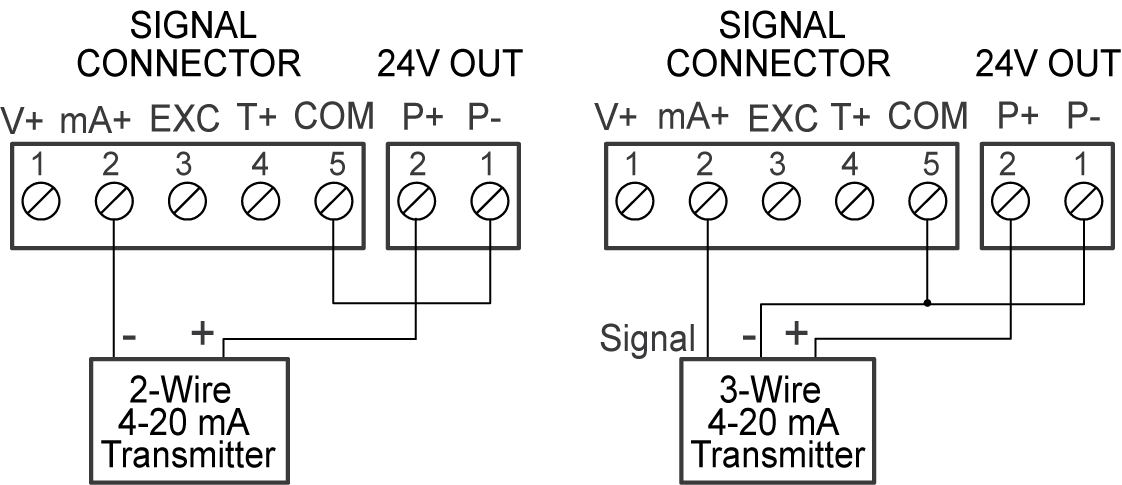

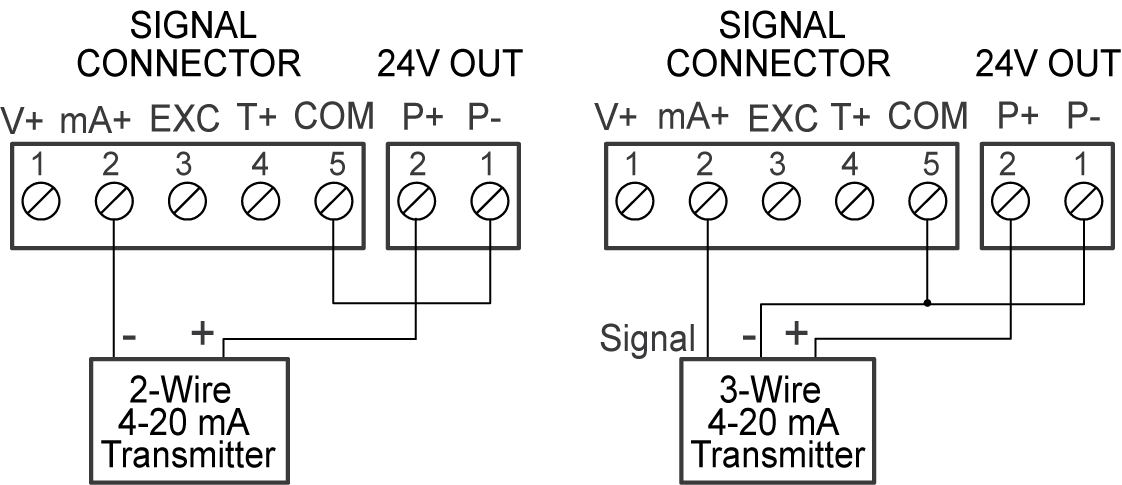

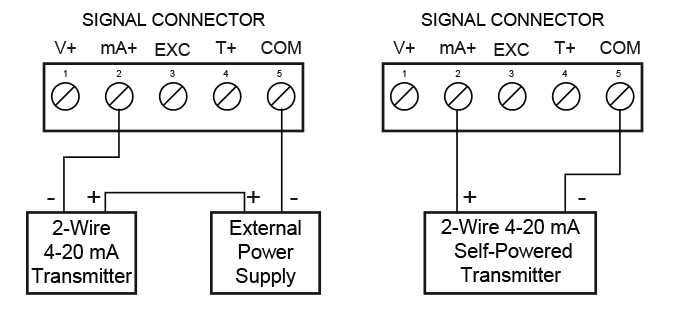

Transmitter Powered by Internal Supply (optional)

Transmitter Powered by External Supply

Current Overload Protection

To protect the instrument from unexpected current overload, the current input circuit contains a resettable fuse. The fuse limits the current to a safe level when it detects a fault condition, and automatically resets itself when the fault condition is removed.

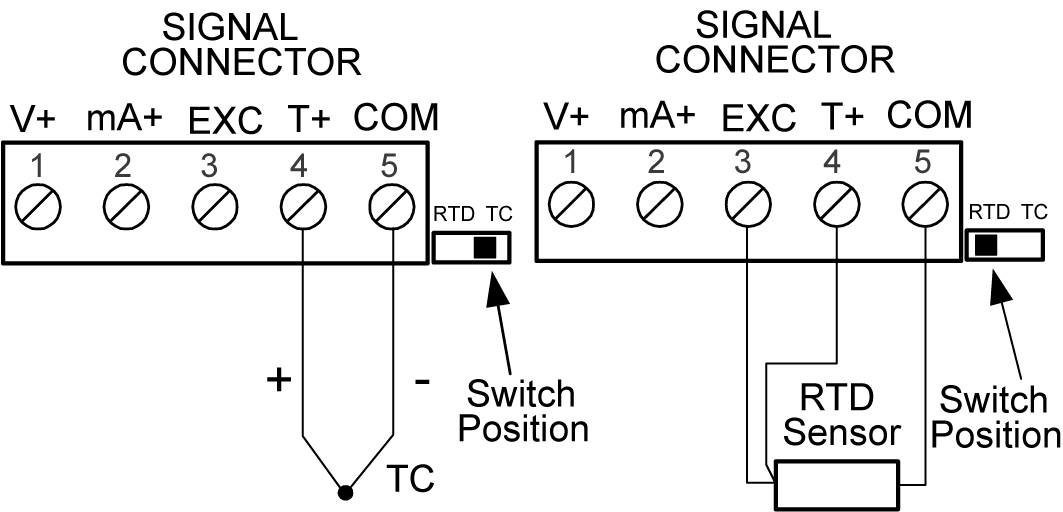

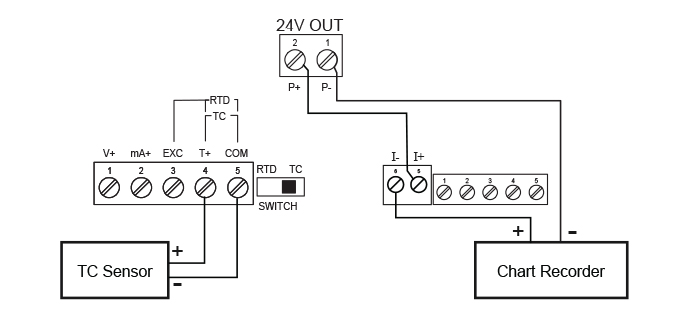

Thermocouple & RTD Inputs

To protect the instrument from unexpected current overload, the current input circuit contains a resettable fuse. The fuse limits the current to a safe level when it detects a fault condition, and automatically resets itself when the fault condition is removed.

Temperature Inputs

The Trident meter accepts J,K,T or E thermocouples and 100 Ω platinum RTDs. For the T thermocouple and RTD, the user can display temperature to 1º or 0.1º resolution and the Type K thermocouple to 2300ºF. In addition, these meters will operate down to -40ºC with only mininal loss of accuracy.

Explosion-Proof Temperature Transmitter with Huge Display

The PD8-765 ProtEx MAX, with the appropriate options, can be used as an explosion-proof, isolated temperature transmitter with a big display by converting the thermocouple or RTD input into an isolated 4-20 mA output.

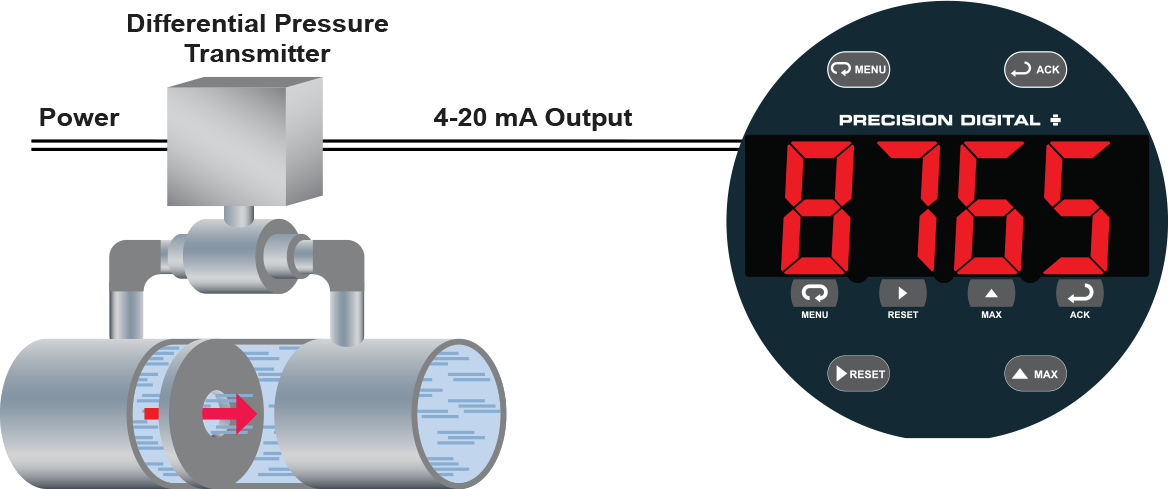

Display Flow Rate From a DP Transmitter

DP Flow via Square Root Extraction

In this application, the PD8-765 is displaying flow rate by extracting the square root from the 4-20 mA signal from a differential pressure transmitter. The user selectable low-flow cutoff feature gives a reading of zero when the flow rate drops below a user selectable value.

Transmitter Power Supplies

24 V @ 200 mA Transmitter Power Supply

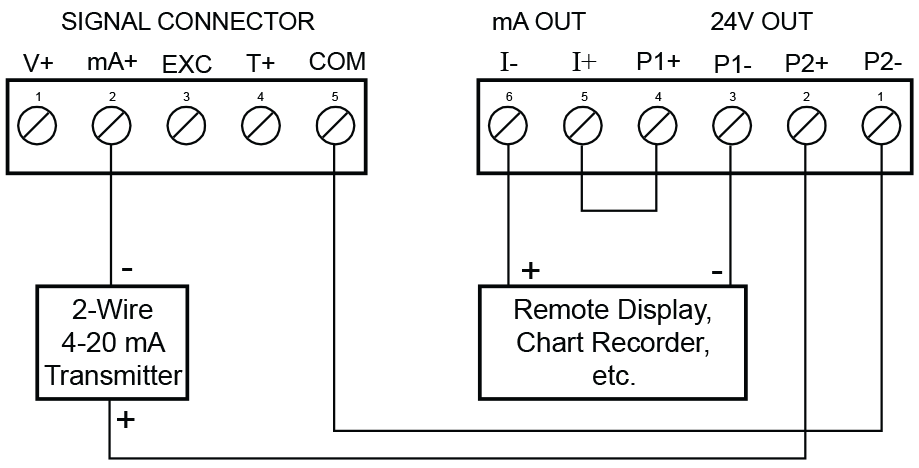

One of the most useful features of the PD8-765 is its built-in, isolated, 24 V @ 200 mA power supply to power the transmitter. This feature saves money by eliminating an external power supply and also simplifies wiring. The following diagrams illustrate how to wire the PD8-765 so it will power the transmitter:

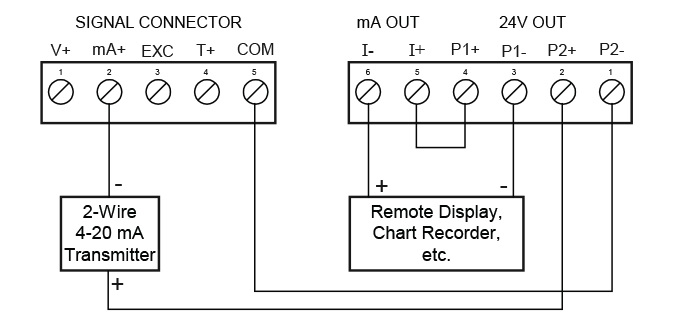

24 V @ 40 mA 4-20 mA Output Power Supply

Not only can the PD8-765 power the 4-20 mA input signal, but an additional power supply of 24 V @ 40 mA is available on select models to power the 4-20 mA output.

Connections for PD8-765-6X3-20 Only

Isolated 4-20 mA Transmitter Output

The PD8-765's isolated 4-20 mA output option converts the meter into a transmitter / loop isolator with a digital display; perfect for temperature applications!

Resettable Fuse Prevents Current Overload

Another very useful aspect of the PD8-765 is that the current input is protected against current overload by a resettable fuse. The fuse limits the current to a safe level when it detects a fault condition, and automatically resets itself when the fault condition is removed.

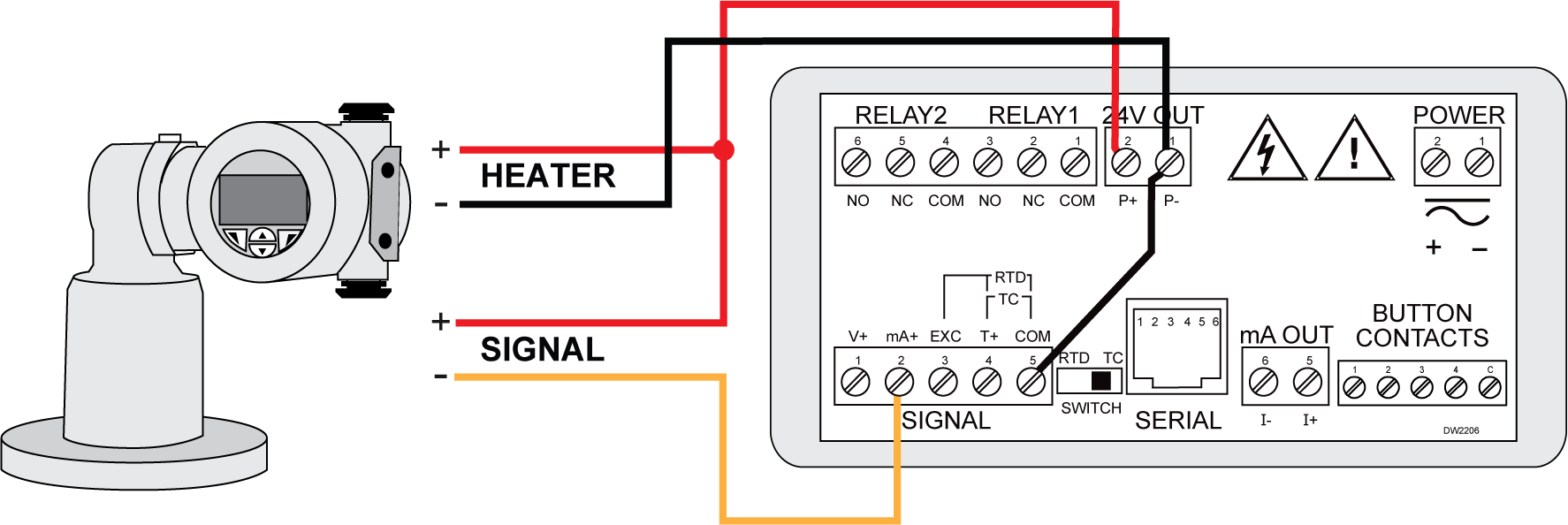

Other Uses for Transmitter Power Supplies

The most common use for these two power supplies is for the 200 mA transmitter power supply to power the field transmitter and 40 mA power supply to power the 4-20 mA output from the meter. However, these two power supplies can be used in other ways. For instance, some level transmitters require the use of a heated lens. The PD8-765’s 200 mA power supply could be used to power both the heated lens and the 4-20 mA signal from the transmitter.

PD8-765 Powers Both the Heater and 4-20 mA Input Signal

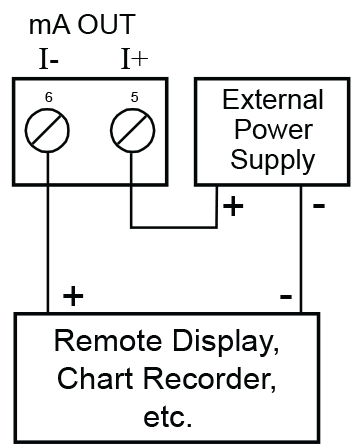

External Power Supply for the Loop

For applications that require an external transmitter power supply, the same PD8-765 is used and merely wired in a different fashion as the following diagrams illustrate:

Advanced Display Features

Four Full Digits

The display on the PD8-765 is four full digits which means it

can display numbers up to 9999. Many digital devices have

displays of only 3½ digits which means they can display only

to 1999. In practical terms, this means the PD8-765 can

display type K thermocouples to 2300ºF and 4-20 mA signals

up to 9,999.

Front Panel LEDs

The meter is supplied with two alarm points that include front panel LEDs to indicate alarm conditions. This standard feature is particularly useful for alarm applications that require visual-only indication.

Large Display Size

The display height on the ProtEX-MAX PD8-765 is an astounding 1.2" (30.5 mm). It can be easily read from distances of up to 30 feet!

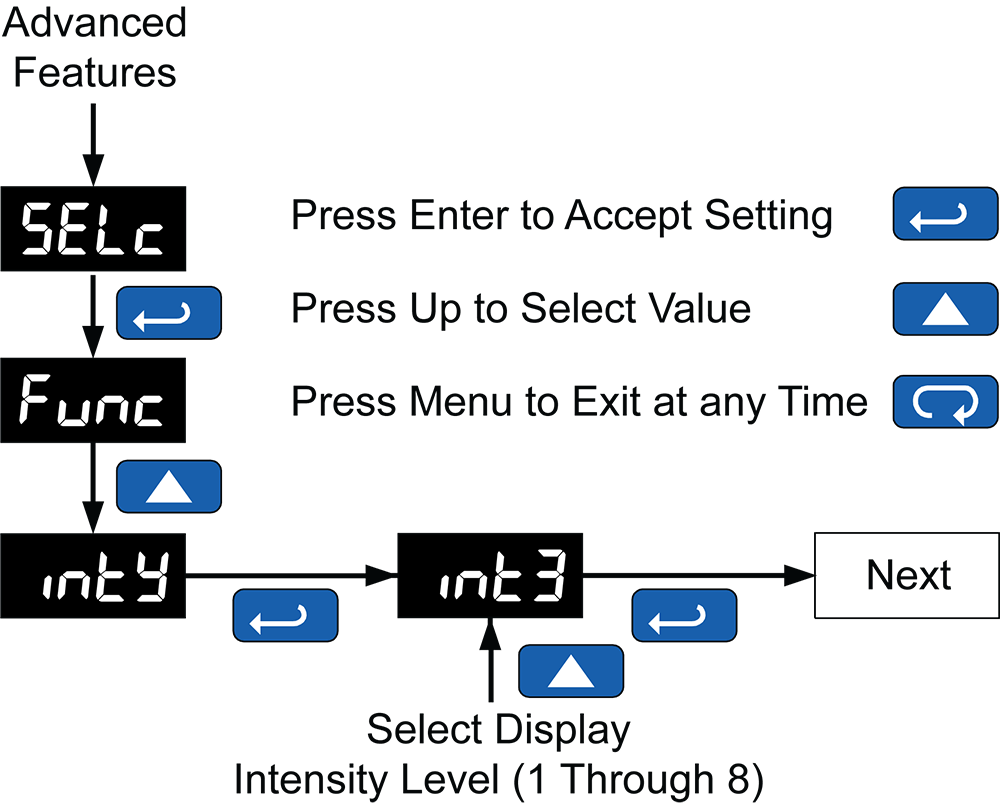

Sunlight Readable Display

The intensity of the display on the ProtEX-MAX PD8-765 can be adjusted to compensate for various lighting conditions, including direct sunlight. In the advanced menu features menu, you can choose from eight levels of intensity depending on the visibility conditions.

The following diagram illustrates how to set the intensity on the PD8-765 process and temperature meter:

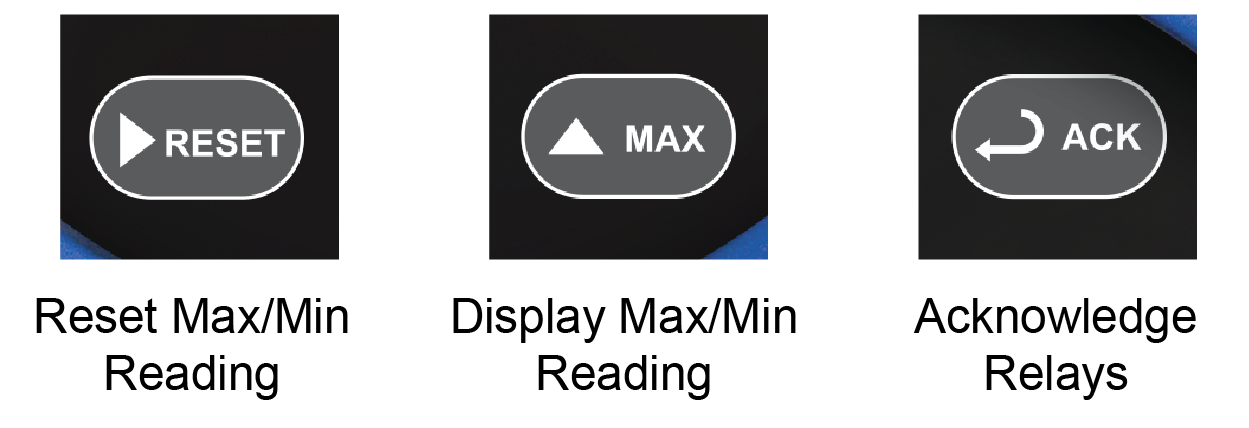

Display & Toggle Maximum / Minimum Reading

The main function of the front panel buttons during operation is to display the maximum and minimum readings reached by the process or temperature inputs. The PD8-765 allows you to toggle between the maximum and minimum readings of the process values. To display the maximum and minimum readings since the last reset/power-up, use the Up arrow/Max button.

Display & Toggle Maximum Value

Display & Toggle Minimum Value

Wide Viewing Angle

Customers can't always look at the display from straight o, so the window and display module have been optimized to provide a wide viewing angle of approximately ±40º; nearly twice that of the competition.

Quick & Easy Scale & Programming Methods

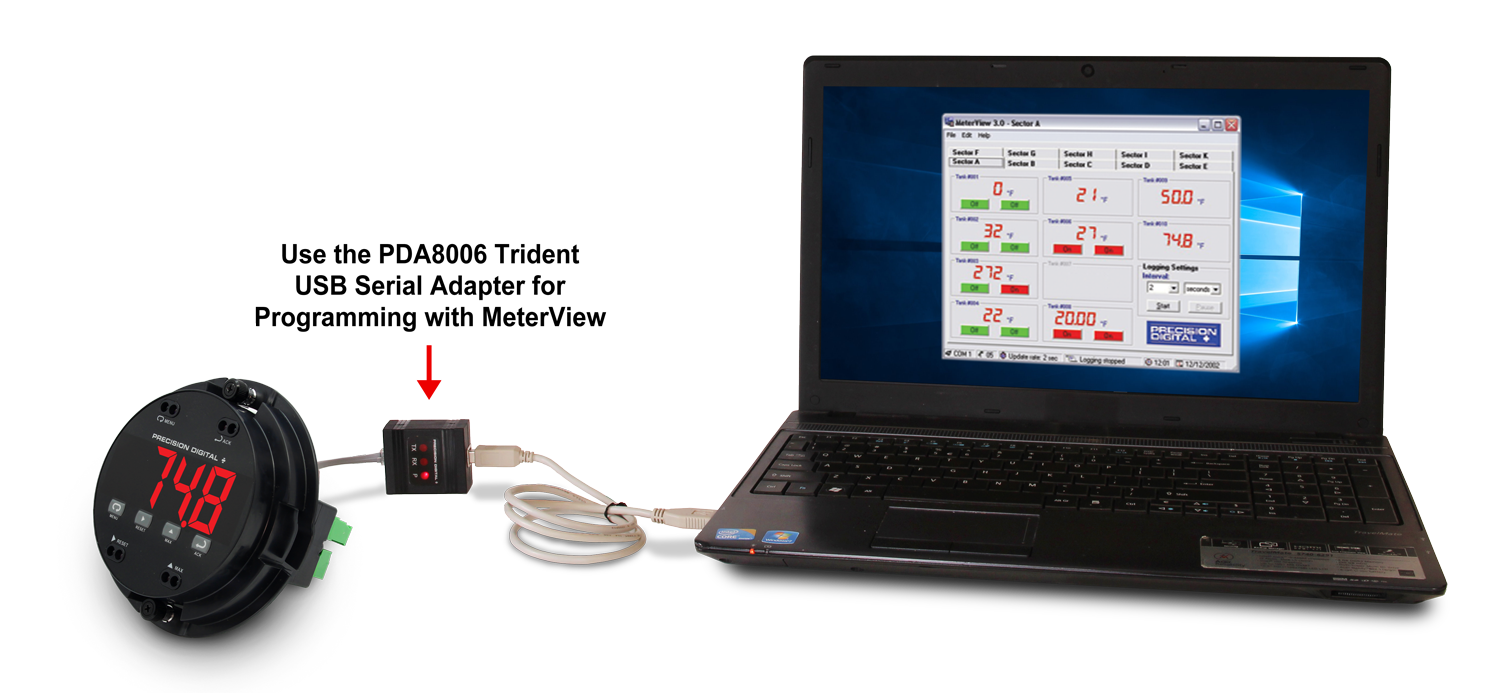

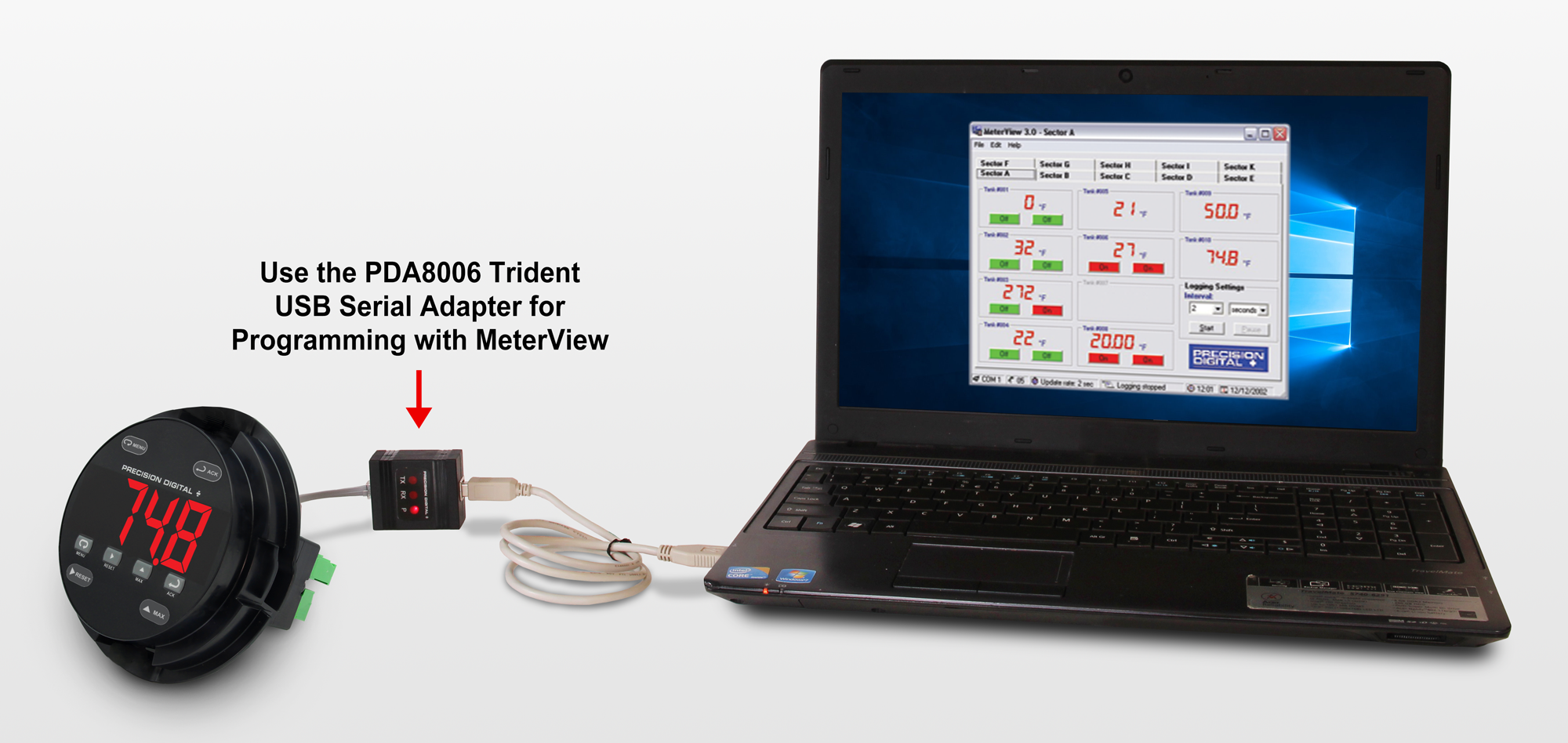

The PD8-765 is easily setup and programmed without removing the cover by using the four through-glass CapTouch buttons or by removing the cover and using the front panel push buttons. The meter can also be programmed using a PC and Precision Digital’s free MeterView software or “cloned” with the Copy function. Programming the PD8-765 with MeterView software requires removing the front cover and connecting to the electronics module to the PC via PDA8006 Trident USB serial adapter.

Free PC-Based MeterView Software

Note: PD8-765 meter is not powered from USB connection and requires external power to be programmed.

MeterView software allows all PD8-765 setup parameters to be programmed from a PC and to save the configuration settings to a file for reporting or programming other meters. For programming purposes, MeterView software connects to the PD8-765 meter via the low-cost PDA8006 USB serial adapter pictured above.

Meter Copy

The Copy function is used to copy (or clone) all the settings from one PD8-765 meter to other PD8-765 meters in less than 10 seconds. The Copy feature does not require a serial communication adapter, it only requires the optional cable assembly (PDA7420).

Note: The PD8-765 modules must be removed from the enclosures to connect the copy cable.

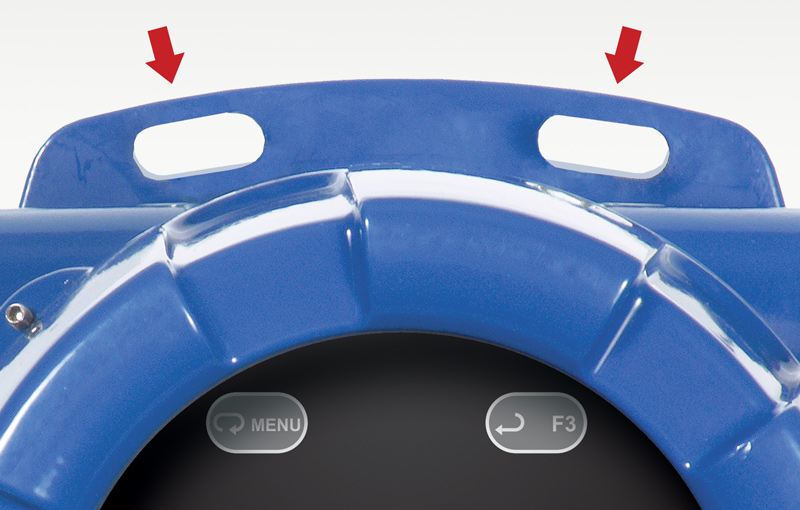

Programming with Four CapTouch Through‑Glass Buttons

The PD8-765’s four CapTouch through-glass buttons keep the user in control of the programming process. There is no need to remove the cover for programming. Just touch the glass over the CapTouch buttons for navigating through the menus. Try out the Trident Virtual Meter at predig.com/tvm and see how simple it is to program the PD8-765. It programs the same exact way as the Trident panel meter version.

CapTouch Through-Glass Buttons

The ProtEX-MAX is equipped with four capacitive sensors that operate as through-glass buttons so that they can be operated without removing the cover (and exposing the electronics) in a hazardous area or harsh environment. CapTouch buttons are designed to protect against false triggering and can be disabled for security by selecting DISABLE on the switch labeled NO-CONTACT BUTTONS located on the connector board.

CapTouch Button Operation

To actuate a button, press one finger to the window directly over the marked button area. When the cover is removed or replaced, the CapTouch buttons can be used after the meter completes a self-calibrating routine. The sensors are disabled when more than one button is pressed, and they will automatically re-enable after a few seconds. When the cover is removed, the four mechanical buttons located on the right of the faceplate are used.

The CapTouch Buttons are configured by default to duplicate the function of the front panel mechanical pushbuttons associated with the integrated meter.

4-20 mA Output & Relays

Isolated 4-20 mA Analog Output

There are several uses for the PD8-765’s isolated 4-20 mA output. For temperature applications, the isolated 4-20 mA output option turns the PD8-765 into an explosion-proof temperature transmitter with a huge display! For 4-20 mA input applications the isolated 4-20 mA output turns the PD8-765 into a signal isolator with the convenience of local display of the process variable. The 4-20 mA output can also be reversed scaled.

Linear 4-20 mA Analog Output

For applications where the input was linearized by the PD8-765, the 4-20 mA output will represent that linearized value.

Convert Temperature Inputs to 4-20 mA Output with the PD8-765

The PD8-765, with the appropriate options, can be used as an isolated, explosion-proof, temperature transmitter with a big display by converting the thermocouple or RTD input into an isolated 4-20 mA output.

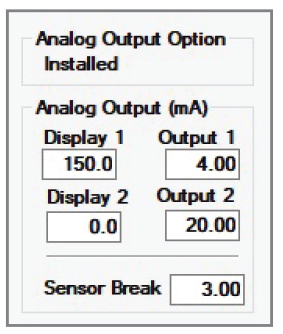

The 4-20 mA output can be reversed scaled such that 4 mA represents the high value and 20 mA represents the low value. For instance, a 4-20 mA output signal could be generated as the meter went from 100.0 to 0.0.

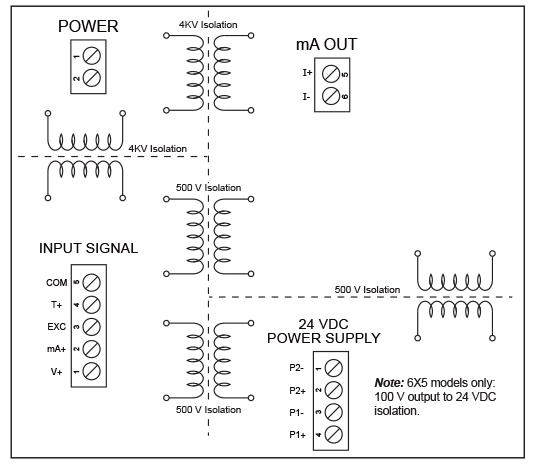

PD8-765 Provides 500 V of Isolation on the Output

The inputs and outputs of the PD8-765 ProtEX-MAX are electrically isolated to prevent ground loops and make wiring easier. All inputs, outputs and power supplies are fully isolated from one another.

Connections

4-20 mA Output & Input Signal Powered by Meter

4-20 mA Output Powered Externally

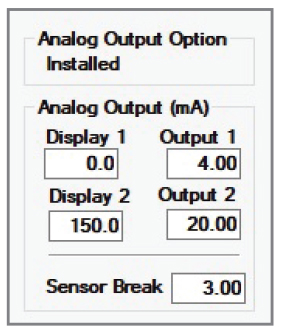

MeterView Software Programming

When a meter is programmed as shown to the left, the output will be 4.00 mA when the display reads 0.0 and the output will be 20.00 mA when the display reads 150.0.

The meter can be set up for reverse scaling as shown to the left: the output will be 4.00 mA when the display reads 150.0 and the output will be 20.00 mA when the display reads 0.0

Sensor Break: Analog output value when TC or RTD sensor break is detected.

Relays for Alarm & Control Applications

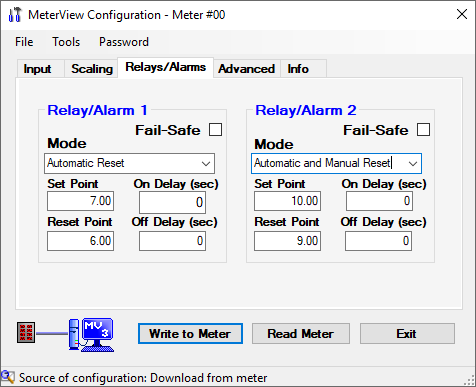

Adding relays to the PD8-765 meter turns it into a sophisticated alarm device as well as a powerful, yet simple, alternative to a more complicated PLC system for control applications. One such application would be pump control using the PD8-765’s relays in pump alternation mode. The PD8-765 can be equipped with two 3 A Form C (SPDT) internal relays. The relays are highly user-configurable as the following screen shot from MeterView indicates:

Setting Set and Reset Points (HI / LO Alarms)

All relays are independent of each other and may be programmed as high or low alarms with user desired set and reset points. Setting a set point above a reset point results in a high alarm and setting a set point below a reset point results in a low alarm. Alarms have 0 – 100% deadband and set and reset points may be set anywhere in the range of the meter.

Resetting the Relays (Mode in MV)

All relays are independent of each other and may be programmed to reset (Mode in MV) in the following ways:

- Automatic: Alarm will reset automatically once the alarm condition has cleared.

- Automatic/Manual: Alarm will reset automatically once the alarm condition has cleared but can also be reset using the ACK front panel button* at any time.

- Latching: Alarm must be reset manually and can be done so at any time. Press the ACK front panel button* at any time to clear the alarm.

- Latching with Reset after Cleared: Alarm must be reset manually and can only be done so after the alarm condition has cleared. Press the ACK front panel button* after the alarm condition has cleared to reset the alarm.

Time Delay (On and Off)

In many applications it is desirable to wait before turning off or on a relay – such as waiting for a process to settle before taking action. Each relay on the ProtEX-MAX PD8-765 can be programmed independently with on and off time delays of 0 to 999.9 seconds to achieve this.

Relays Auto Initialization

When power is applied to the meter, the front panel LEDs and alarm relays will reflect the state of the input to the meter.

Signal Loss Relay Operation (Sensor Break)

The meter can be programmed so that when it detects a break in the RTD or thermocouple signal, the relay will go to either the alarm or non-alarm state.

Note: This does not apply to voltage or 4-20 mA signals.

User Selectable Fail-Safe Operation

All relays are independent of each other and may be programmed for user selectable fail-safe operation. With the fail-safe feature activated, the relays will transfer to the alarm state on power loss to the meter.

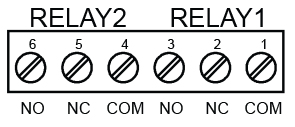

Relay Connections

Relay connections are made to a six-terminal connector labeled RELAY1 and RELAY2.

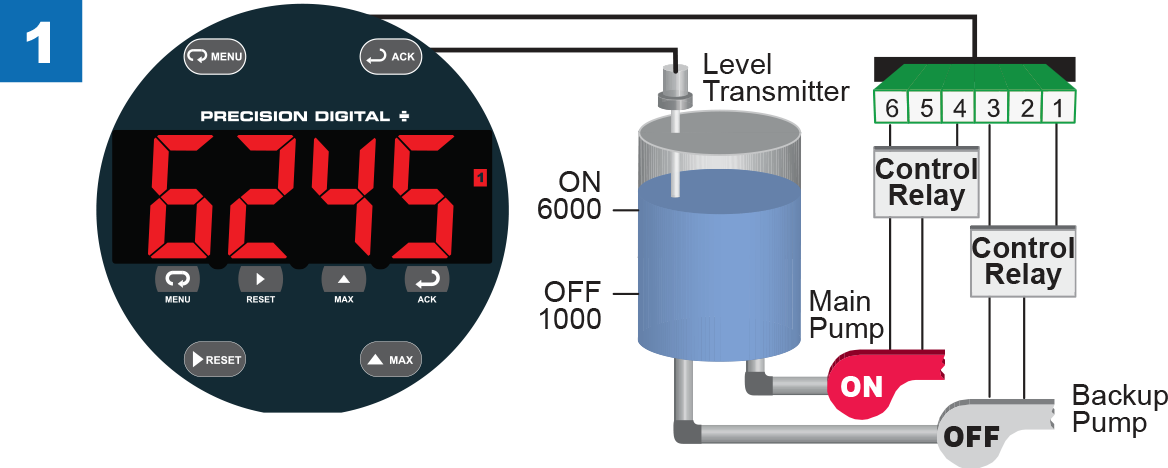

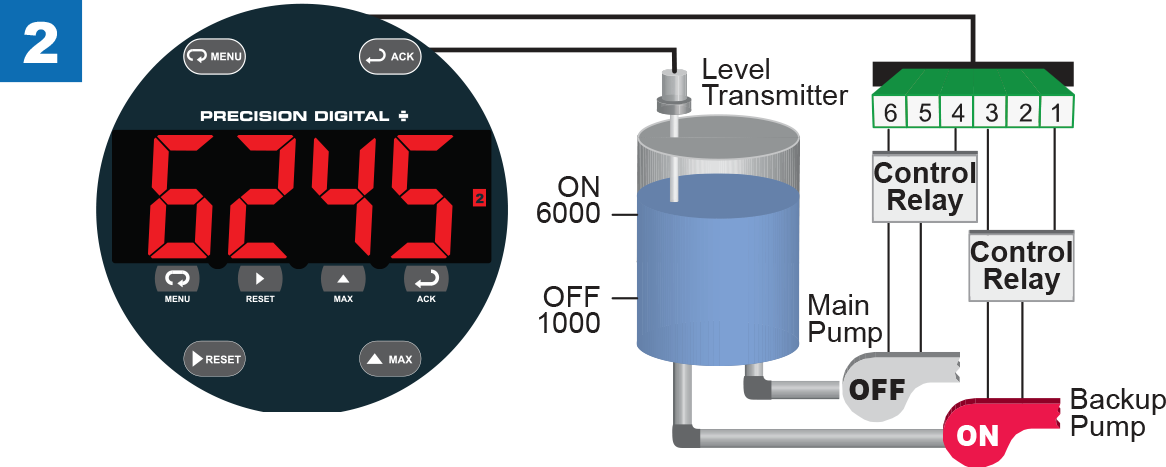

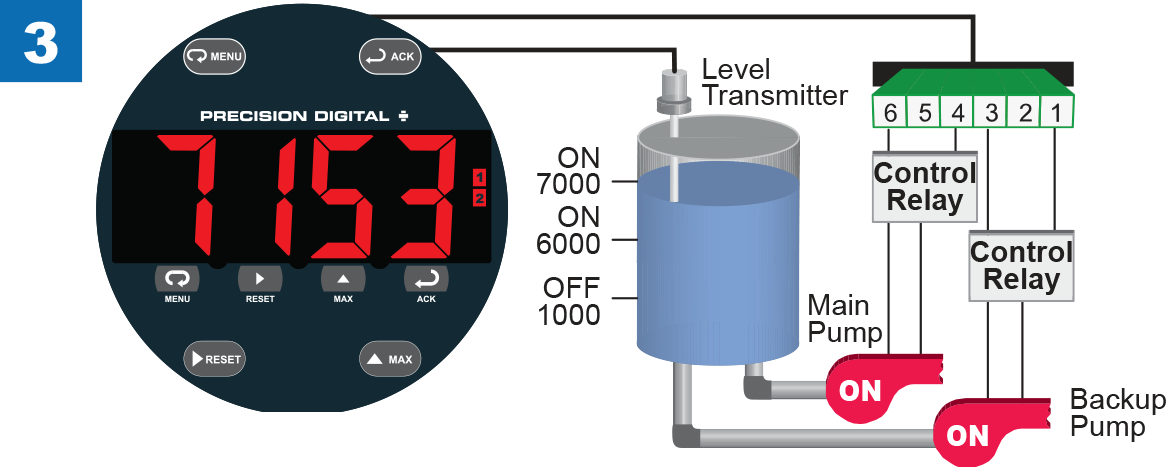

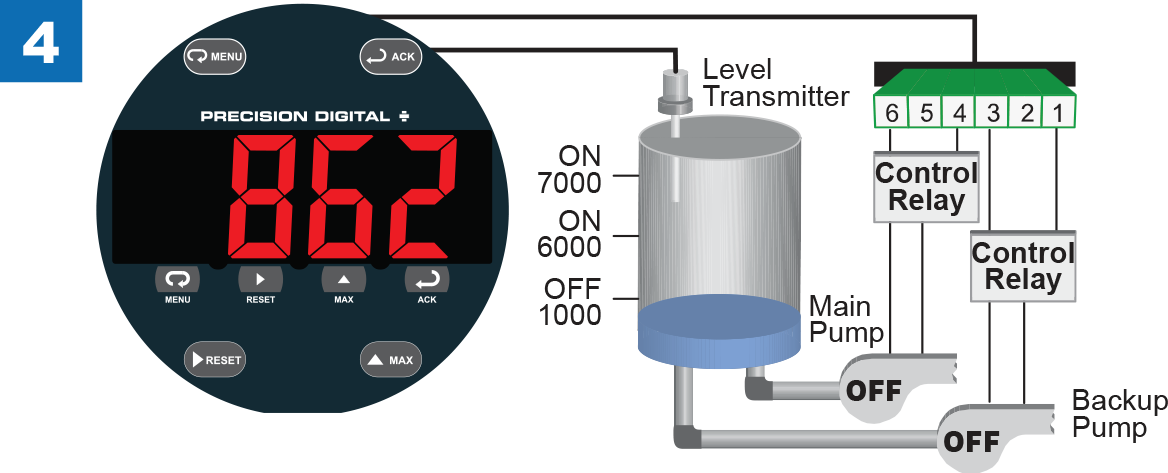

Explosion-Proof Pump Controller with Dual-Pump Alternation

The PD8-765 can be used as an explosion-proof pump controller when combined with a continuous level transmitter. One of the most common pump control application is shown below: controlling and alternating two pumps. The goal is to control the level between 1000 and 6000 gallons. The main pump turns on when the level reaches 6000 gallons and pumps down to 1000 gallons and then shuts the pump off. The next cycle, the backup pump turns on at 6000 gallons and shuts off at 1000 gallons. If at any time the active pump can’t keep the level below 7000 gallons, the other pump would come on also.

Visit predig.com/PD8-6000 for details.

Serial Communications

Modbus RTU Serial Communications

With onboard RS-485 serial communication, the PD8-765 can communicate with any Modbus master device using the popular Modbus communications protocol that is included in every PD8-765.

Serial Adapters & Converters*

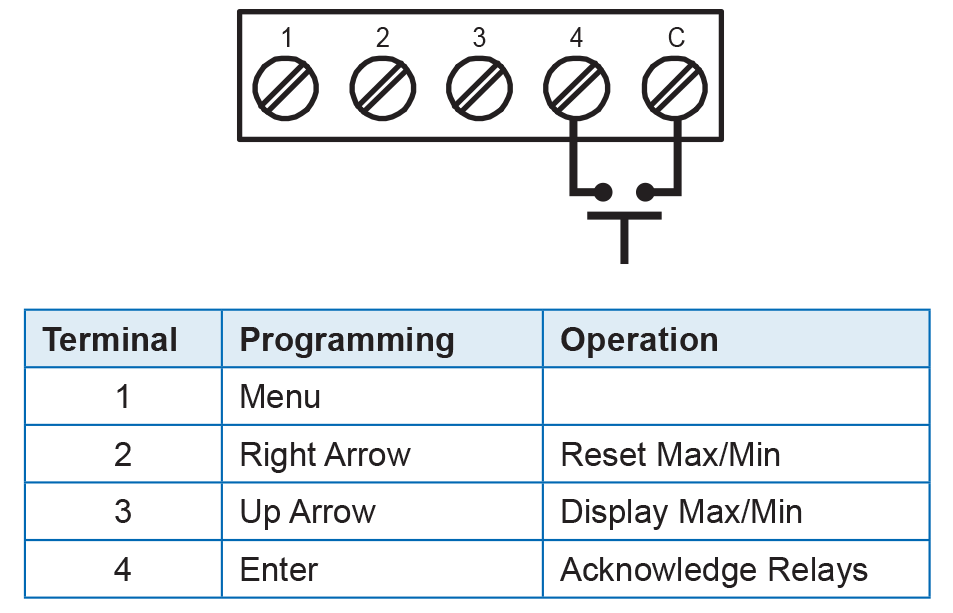

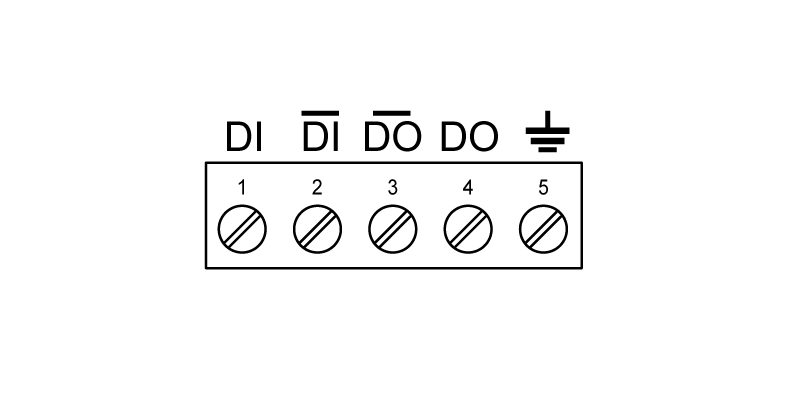

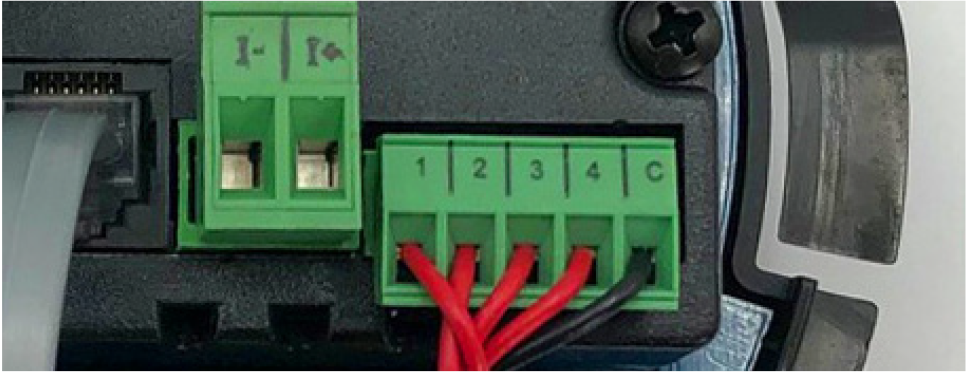

Integrated External Button Contacts and Serial Communications

External Button Connections

Four external button contacts come standard with the ProtEX MAX PD8-765. These button contacts are used to remotely operate the front panel buttons and can be used for programming and resetting the relays.

Note: The integrated button contacts (1-4) function identically to the front panel pushbuttons / CapTouch buttons (Menu, Reset, Max, & ACK) and are nonconfigurable.

Serial Communications Connections

PD8-765 meters come with an RS-485 connection for serial communications with other digital devices. The industry standard Modbus RTU protocol is included with every meter.

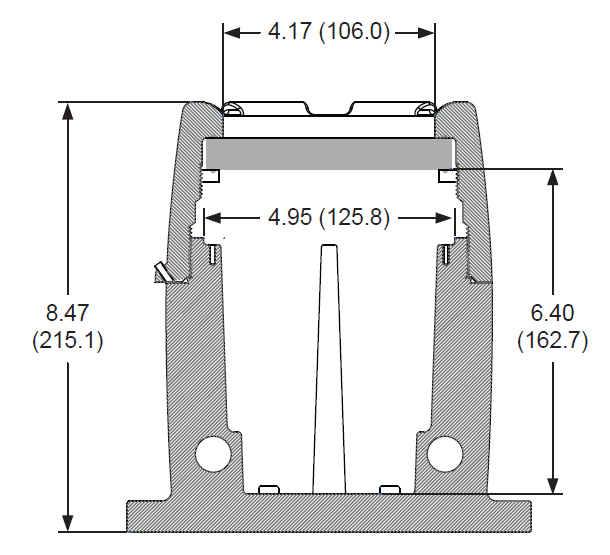

Physical Features

The ProtEX-MAX PD8-765 is designed for ease-of-use in safe and hazardous applications. The ProtEX-MAX is housed in a rugged NEMA 4X explosion-proof enclosure, can operate over a wide temperature range, includes removable screw terminal connectors, has worldwide approvals for use in hazardous areas, and features through-glass buttons for easy meter operation without the need to remove the cover. All of these features are backed by a 3-year warranty.

Super-Bright LED Display

The PD8-765 features a 1.2" high 4-digit display with super‑bright LEDs, our brightest ever. These allow the display to be read in any lighting condition, even in direct sunlight.

CapTouch Through-Glass Buttons

The ProtEX-MAX is equipped with four capacitive sensors that operate as through-glass buttons so that it can be programmed and operated without removing the cover (and exposing the electronics) in a hazardous area. These buttons can be disabled for security by selecting the DISABLE setting on the NO-CONTACT BUTTONS switch located on the back of the electronics module, inside the enclosure.

Rugged Explosion-Proof Enclosure

The ProtEX-MAX is housed in a rugged NEMA 4X, 7, & 9, IP68 aluminum or stainless steel enclosure, designed to withstand harsh environments in safe and hazardous areas.

Wide Viewing Angle

Customers can’t always look at the display from straight on, so the window and display module have been optimized to provide a wide viewing angle of approximately ±40º; nearly twice that of the competition.

Built-In Mounting Flanges

The PD8-765 is equipped with four slotted flanges for wall mounting or NPS 1½" to 2½" or DN 40 to 65 mm pipe mounting.

Flexible Mounting & Wiring

The PD8-765 features four ¾" NPT conduit openings so that wiring can be routed to the most convenient conduit connection(s).

Rotatable Display

The PD8-765 rotatable display, along with four available conduit connections, provide for numerous installation options. The display can be rotated in 90º increments. Rotate it 90º for horizontal mounting.

PDA-SSTAG Stainless Steel Tags

PDA-SSTAG is a laser etched stainless steel tag accessory for any Precision Digital meter. The tag features custom text for equipment identification, instruction, or whatever else is needed in your facility. Each tag comes with a stainless steel wire and lead seal for easy mounting wherever you need it.

Wide Operating Temperature Range

The ProtEX-MAX can operate from -55 to 60°C (-67 to 140°F) meaning it can be installed in a wide variety of indoor and outdoor industrial applications.

Removable Screw Terminal Connectors

Industrial applications require screw terminal connections for easy field wiring and the PD8-765 goes one step further in convenience by also making them removable.

Operational Features

CapTouch Buttons & External Button Contacts

The main function of the CapTouch buttons during operation is to display the maximum and minimum readings reached by the process or temperature inputs as well as acknowledge relays.

1. CapTouch Button Functions

The following CapTouch buttons can perform these functions:

2. Front Buttons Behind Glass

The front buttons behind the glass can be used to manually program the PD8-765 meter by removing the front cover. A more convenient way is to use the CapTouch buttons or MeterView software. See manual for details.

3. External Button Contacts

The PD8-765 is equipped with four external button contacts that can be connected to another device to remotely program and operate the instrument.