Note: PD765 or PD8-765 meters are not powered from USB connection and require external power to be programmed.

Features

- Works with PD765 and PD8-765 Models

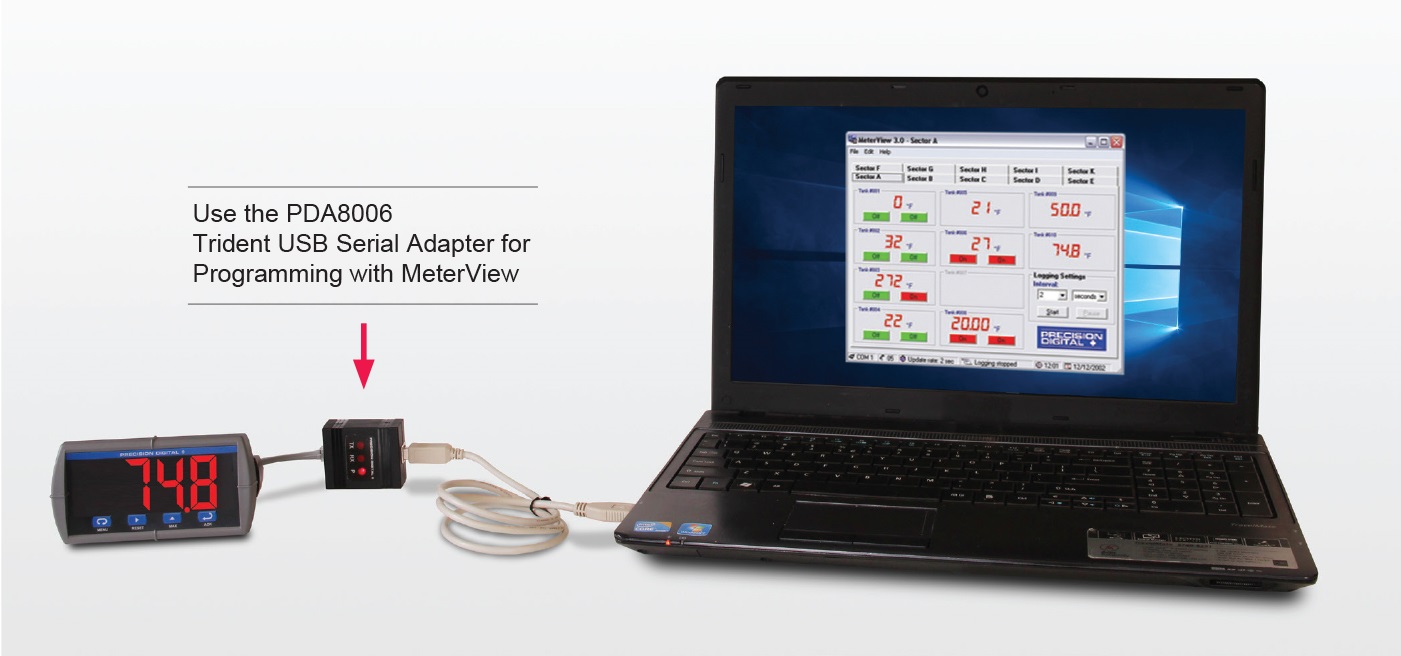

- USB Connection for Programming with PDA8006 Adapter

- Program or Read Meter Settings

- Save Meter Profiles for Cloning

- Configure Meter Input

- Configure Relay and Alarm Settings

- Edit Advanced and Security Settings

- Log Up To 100 Meters

- Data Saved in HTML Data Files

- Free Download

MeterView™ software allows all PD765 or PD8-765 setup parameters to be programmed from a PC and to save the configuration settings to a file for reporting or programming other meters. For programming purposes, MeterView software connects to the PD765 or PD8-765 meter via the low-cost PDA8006 USB serial adapter pictured above.

Meter Copy

The Copy function is used to copy (or clone) all the settings from one PD765 or PD8-765 meter to other PD765 or PD8-765 meters in less than 10 seconds. The Copy function is a standard feature on all PD765 or PD8-765 meters. The Copy feature does not require a serial communication adapter, it only requires the optional cable assembly (PDA7420).

Programming with Four Front Panel Buttons

The PD765 or PD8-765 four front panel buttons keep the user in control of the programming process. To see how simple it is to program the PD765 or PD8-765, check out the Virtual Meter at www.predig.com/tvm.

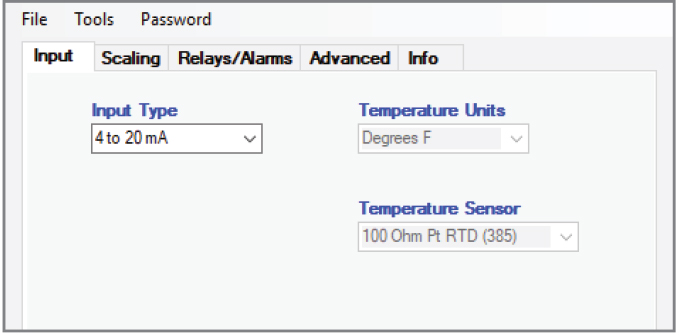

Programming From a PC with MeterView™

Precision Digital’s free MeterView™ software allows all PD765 or PD8-765 setup parameters to be programmed from a PC and to save the configuration settings to a file for reporting or programming other meters. For programming purposes, MeterView software connects to the PD765 or PD8-765 meter via the low-cost PDA8006 USB serial adapter. Below are examples of the various windows used to configure, scale, set relays / alarms, and program other advanced features.

Configure Input

- Input type

- Temperature units

- Sensor type

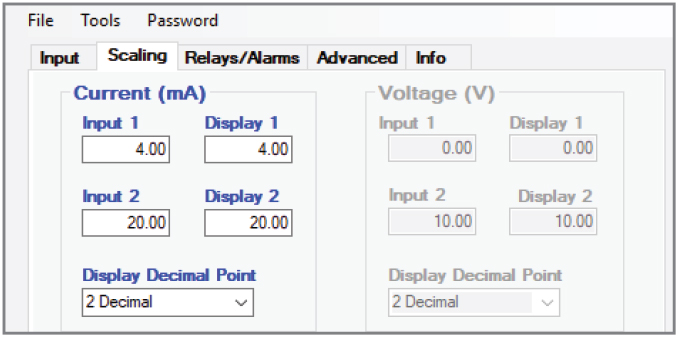

Meter Scaling

- Scale input

- Decimal point

- No cryptic codes

- Simple to use

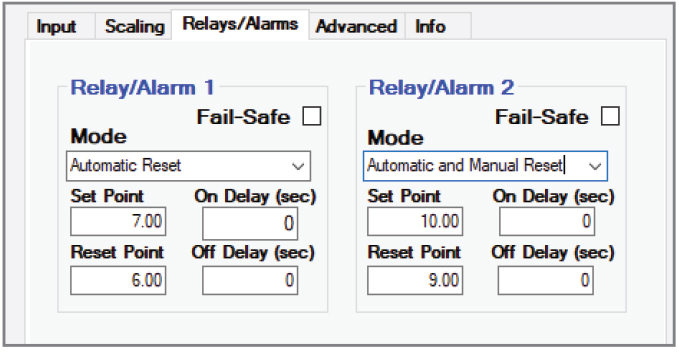

Set Relays/Alarms

- Select reset mode

- Set/reset points

- Fail-safe operation

- On & off delays

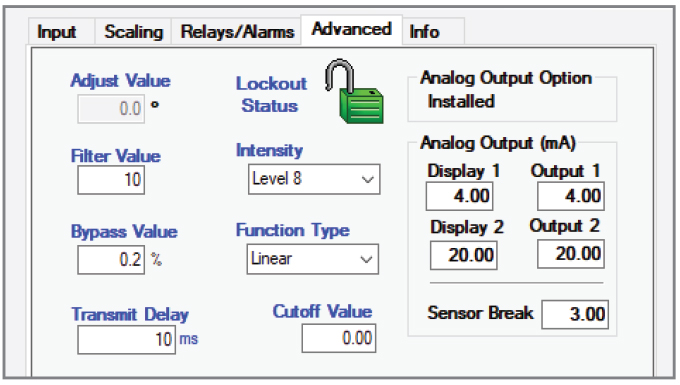

Advanced Settings

- Password

- Filter & bypass

- Transmit delay

- Display intensity level

- Function type

- Analog output scaling

- Sensor break

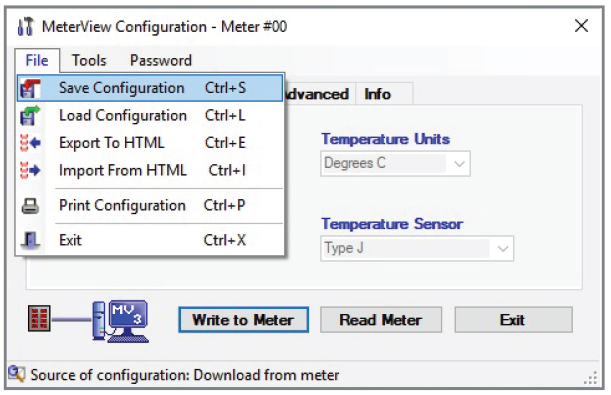

Save/Retrieve Configuration

MeterView™ software allows all PD765 or PD8-765 setup parameters to be programmed from a PC and to save the configuration settings to a file for reporting or programming other meters. For programming purposes, MeterView software connects to the PD765 or PD8-765 meter via the low-cost PDA8006 USB serial adapter.

Data Acquisition

Digital panel meters make a great front end to a PC-based data acquisition system. They are easy to set up, can be used for a wide range of inputs, will power the transmitter, and best of all provide a local display of the process. Precision Digital has the perfect package with its PD765 or PD8-765 Meters, a wide selection of serial adapters and converters and free MeterView™ software. Data is displayed on the PC and written to a file that could then be imported into a spreadsheet or other application.

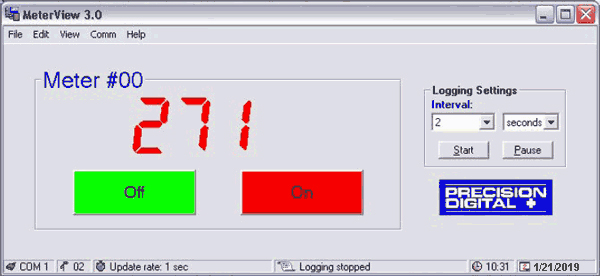

Monitor One Meter

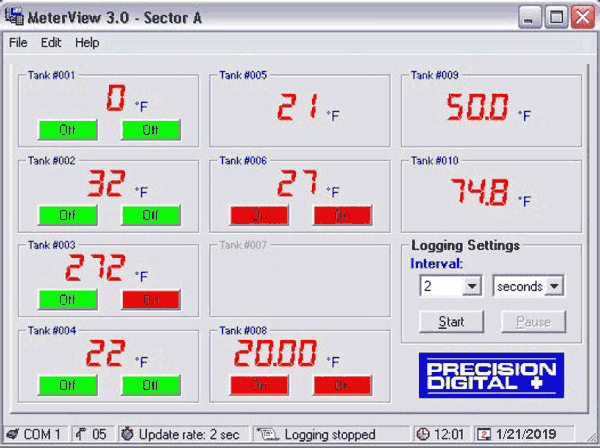

Monitor One to Ten Meters

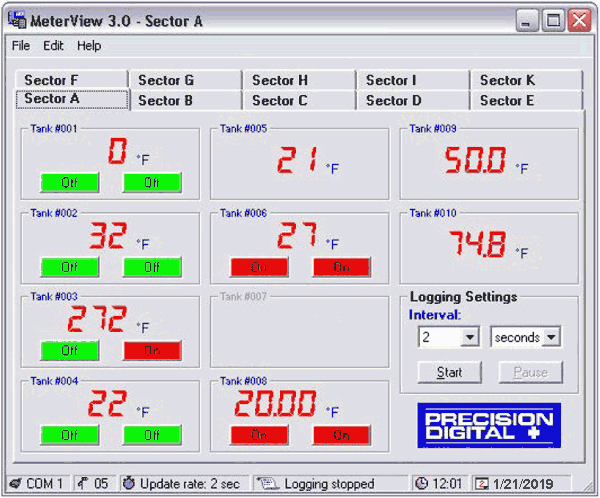

Monitor One to One Hundred Meters

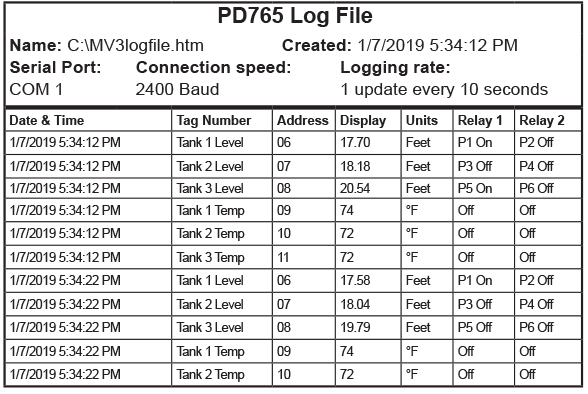

Sample File Generated by MeterView™

Calibration Reporting

Printed by MeterView 3.00 - Build 2060 Printed on 3/18/2019 3:45:28 PM

PD765 Configuration - Meter #00

Input Configuration

Input selected: 4 to 20 mA

Decimal point: ddd.d

Temperature unit: Degrees F

Temperature sensor: Type J

Current Scaling (4-20 mA)

Input 1: 4.00

Display 1: 0.0

Input 2: 20.00

Display 2: 200.0

Voltage Scaling (0-10 V)

Input 1: 0.00

Display 1: 0.0

Input 2: 10.00

Display 2: 50.0

Relay/Alarm 1 Settings

Action: Automatic Reset

Fail-safe: Off

Set point: 40.0

On Delay: 0

Reset point: 10.0

Off Delay: 0

Relay/Alarm 2 Settings

Action: Automatic Reset

Fail-safe: Off

Set point: 40.0

On Delay: 0

Reset point: 10.0

Off Delay: 0

Display Response Variables

Adjustment: 0.0

Filter: 10

Bypass: 0.2

Transmit delay: 0

Miscellaneous

Password: _ _ _ _

Meter address: 00

Serial number: 200111201423430

Factory Calibration Constants

Current gain: 0.0340963

Current offset: -0.1501465

Voltage gain: 0.0175513

Voltage offset: -1.0410160

Test gain: 0.0169000

Test offset: -0.0507000

TC Type J gain: 1.0454590

TC Type J offset: 6947.075

TC Type J CJ ref.: 34415.38

TC Type K gain: 1.0459060

TC Type K offset: 6910.510

TC Type K CJ ref.: 34463.38

TC Type T gain: 1.0452330

TC Type T offset: 6920.954

TC Type T CJ ref.: 34447.75

TC Type E gain: 1.0452550

TC Type E offset: 6951.981

TC Type E CJ ref.: 34443.00

RTD 100 Ohm PT (385) gain: 1.0422950

RTD 100 Ohm PT (385) offset: 6221.340

RTD 100 Ohm PT (392) gain: 1.0422950

RTD 100 Ohm PT (392) offset: 6221.340

Specifications

System Requirements: Windows® 95/98/ME/NT4/2000/XP/ Vista/7*/ Windows® 10

Communications: RS-232 adapter or RS-485 adapters with an RS-232 to RS-485 or USB to RS-485 converter may be used for communicating with the meters.

USB Adapter for Programming Only: For programming purposes, MeterView software connects to the PD765 or PD8-765 meter via the low-cost PDA8006 USB serial adapter.

Number of Meters: Up to 100 meters simultaneously with addressing capability; minimum scan time for 100 meters: 60 sec

Meter Address: 00 to 99

Baud Rate: 300 bps to 19,200 bps; selection must match the baud rate selected in the meters.

Screen Update Rate: Dependent on system and meter settings. Rates of up to 10 meters/second are attainable at 19,200 bps.

Configuration: Configure meter settings one meter at a time.

Configuration Report: Save configuration to PDC file format or export to HTML for printing, cloning, or restoring meter.

Logging Interval: 2 seconds to 60 hours or manual

Manual Logging: Data saved to file when Log button is pressed.

Data Logging Report: Log data to HTML file format. All enabled meters are logged to a single file.

Alarm Notification: Pop-up message indicates new alarm condition. Alarm alert notification may be disabled.

Event Log: Important events are logged with date and time stamp.

Relay/Alarm Status: Indicate relay/alarm status with customized color and message label. Relay status indication may be disabled.

Units & Tag Number: Show engineering units and tag number information; these settings are not saved to the meter.

Relay Acknowledge: Relays may be acknowledged by clicking on corresponding Relay Status button. Meters must be set up for manual reset and Relay Mode must be enabled in MeterView™.

*Note: Windows 32-bit operating systems only

The Information contained in this document is subject to change without notice. Precision Digital Corporation makes no representations or warranties with respect to the contents hereof, and specifically disclaims any implied warranties of merchantability or fitness for a particular purpose.