Features

- 1/8 DIN Loop-Powered Process Meters with NEMA 4X, IP65 Front

- 4-20 mA Input Displayed with ±0.02% FS Accuracy

- 1.5 Volt Drop (4.5 Volt Drop with Backlight)

- 0.7" (17.8 mm) 5 Digits 7-Segment, FT-IN & Fractions, Top Display (PD6603)

- 0.7" (17.8 mm) 5 Alphanumeric Characters Top Display (PD6602/4)

- 0.4" (10.2 mm) 8 Alphanumeric Characters Bottom Display

- Displays Level in Feet & Inches up to 999 Feet, 11 & 15/16 Inches (PD6603)

- 20-Segment Bargraph with Numeric Percent Indication, Optional

- (2) Open Collector Outputs Standard; Assignable to Pulse, Alarm, Timer, or Stopwatch

- (2) Optional Loop-Powered Solid-State Relays; Assignable to Alarm, Control, Timer, or Stopwatch

- Stopwatch & Timer Functions to Drive Relays & Open Collectors

- Optional Isolated 4-20 mA Analog Output

- Relay Pump Alternation Based on Level and Runtime

- Display Relay Runtime & Cycle Count via Relay Info Menu

- Round Horizontal Tank Function; Just Enter Diameter & Length

- 32-Point Linearization, Square Root Extraction and Programmable Exponent Function

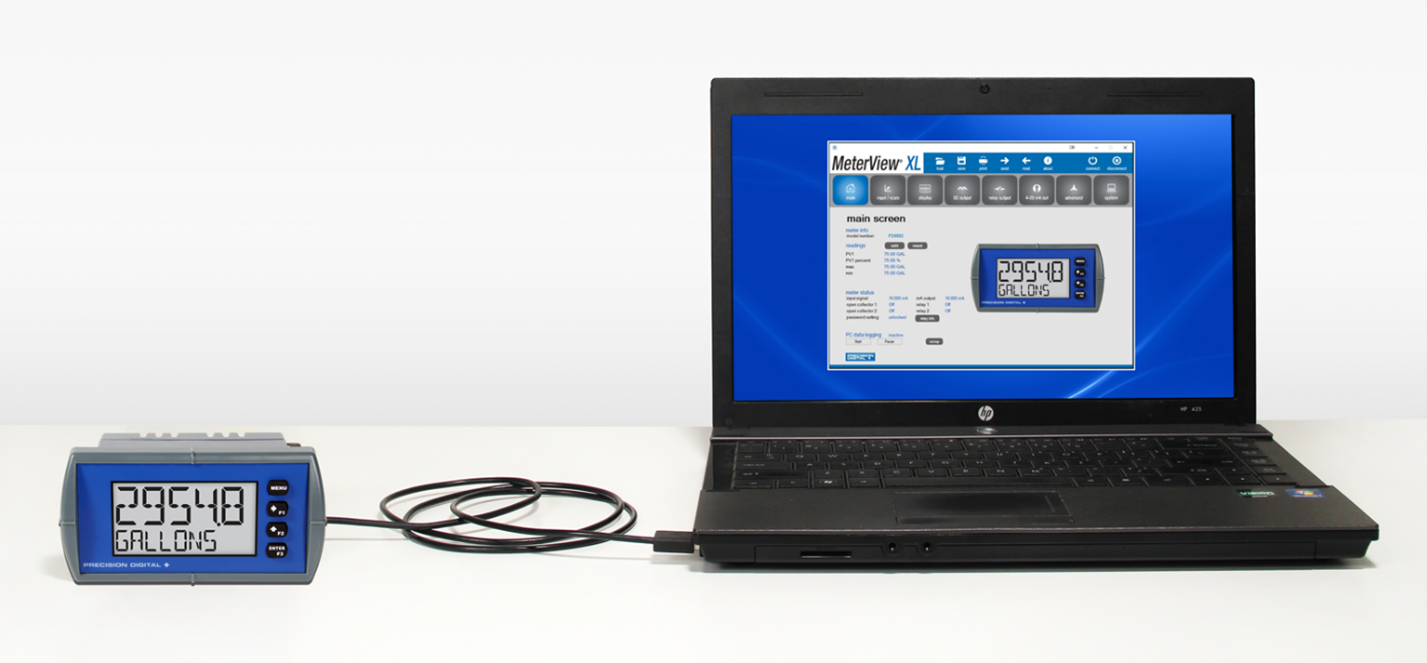

- Free PC-Based MeterView XL USB Programming Software

- Loop-Powered Backlight with Red Backlight for Alarm Conditions

- Operating Temperature Range: -40 to 167°F (-40 to 75°C)

- Conformal Coated PCBs for Dust & Humidity Protection

- 3-Year Warranty

Why Use Loop-Powered Meters?

The most basic decision a user wishing to display a 4-20 mA signal on a digital display has to make is: should the meter be powered by line voltage or should it be powered by the 4-20 mA loop?

There are three main benefits of using loop-powered devices:

- No additional power required

- Easy wiring

- Additional digital displays can easily be added in the same loop

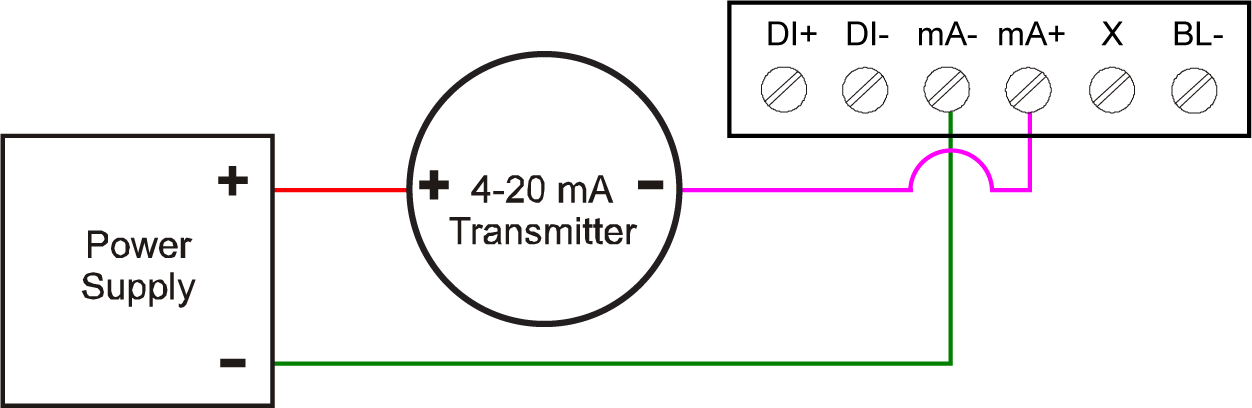

The following diagram illustrates how a loop-powered meter is wired. Notice there are only two connections made to the meter.

For more information on loop-powered meters, check out Fundamentals of Loop-Powered Devices and Loop-Powered vs Line-Powered Meters white papers.

Overview

Loop-Powered Indicators with Advanced Display and Control Features

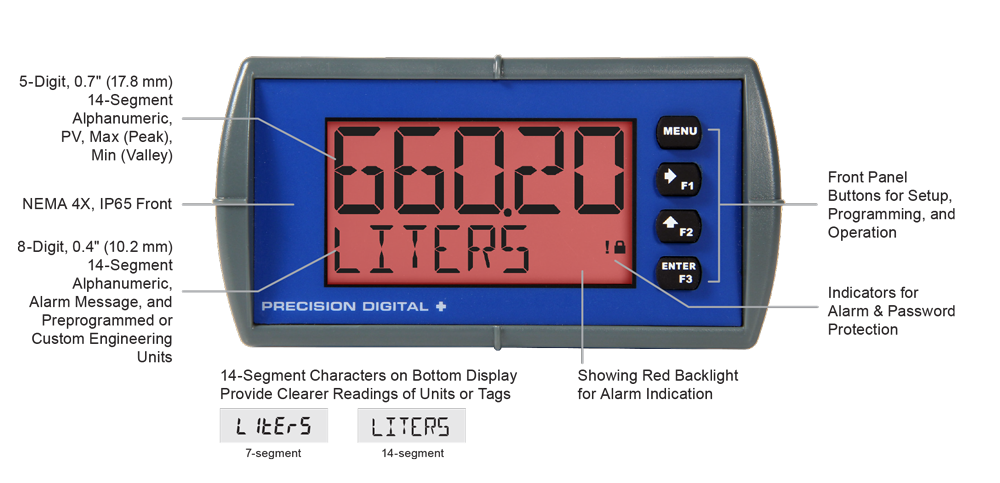

These loop-powered 1/8 DIN digital panel meters can be installed virtually anywhere to provide convenient and informative display of any 4-20 mA signal. One of the most convenient features of these instruments is their dual line display, which is typically used to display the process variable on the 5-digit alphanumeric top display and the units of measure or a tag on the 8-digit alphanumeric bottom display. Feet and inches models display level in feet and inches on the top display while the 8-digit alphanumeric bottom line may be used to display a tag or custom message.

Further enhancing the display on these instruments is a 20-segment bargraph available on the PD6603 and PD6604 that also includes a numeric value of the percentage the bargraph represents.

Free, PC-based, MeterView XL software that connects to the meter via a micro USB cable is available for programming and setup of the meters. All models come equipped with two open collector outputs and a digital input. There are also models available with two solid-state relays and isolated 4-20 mA analog output options. The open collector outputs are useful for alarm indication. The digital input can be used to acknowledge the relays, to start/stop a timer/stopwatch, and more. The relays can be programmed for alarm indication, on/off control, or pump alternation.

For intrinsically safe and nonincendive versions of these instruments please click here.

Front

- 5-Digit alphanumeric top line

- 8-Digit alphanumeric bottom line

- Feet & inches on top line

- 8-Digit alphanumeric bottom line

- 20-Segment bargraph with numeric percentage

- 5-Digit alphanumeric top line

- 8-Digit alphanumeric bottom line

- 20-Segment bargraph with numeric percentage

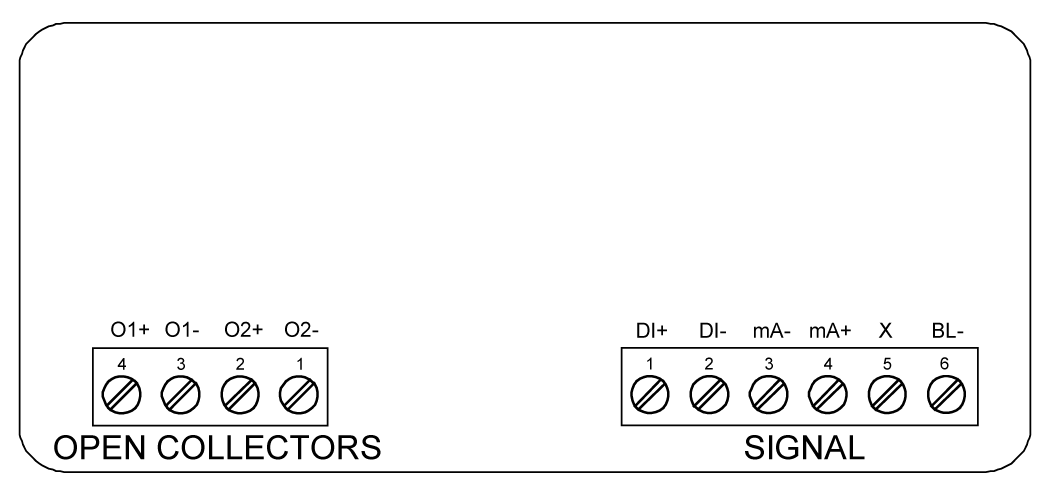

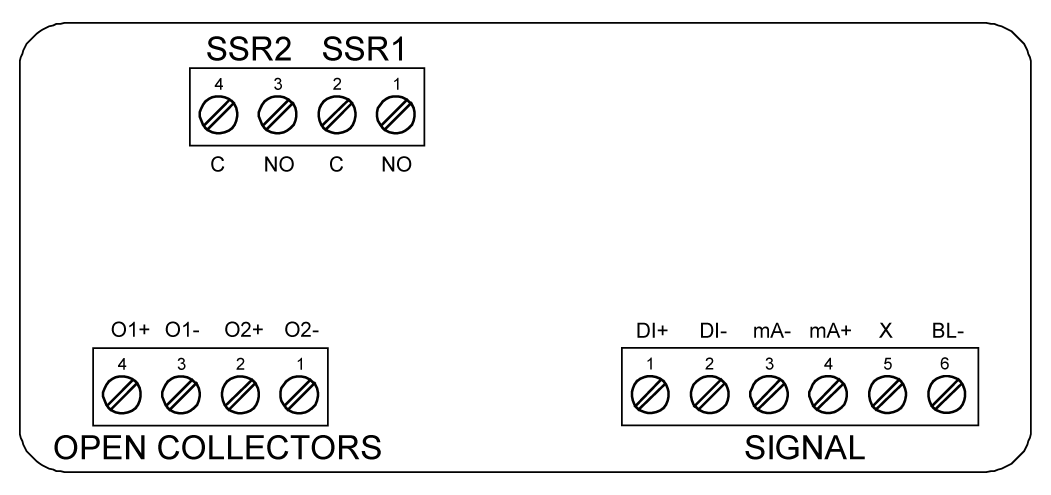

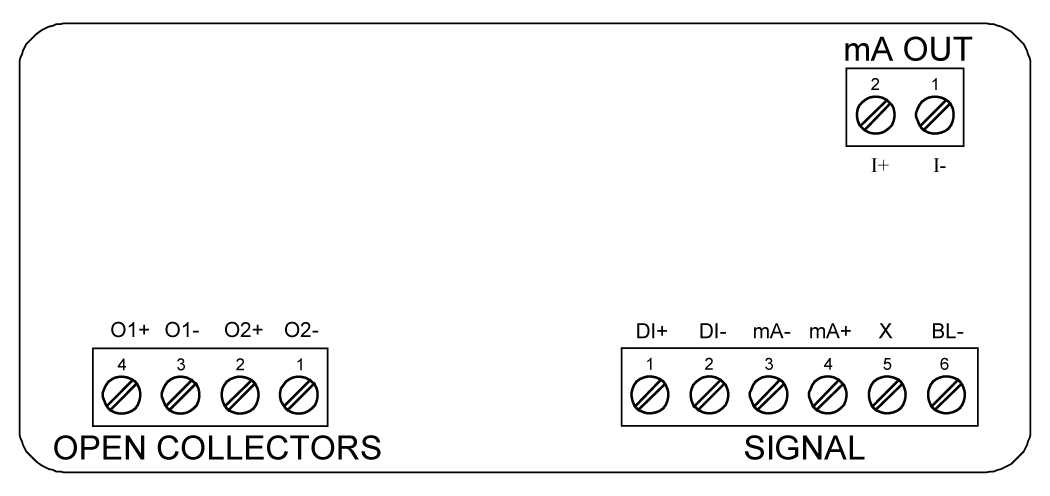

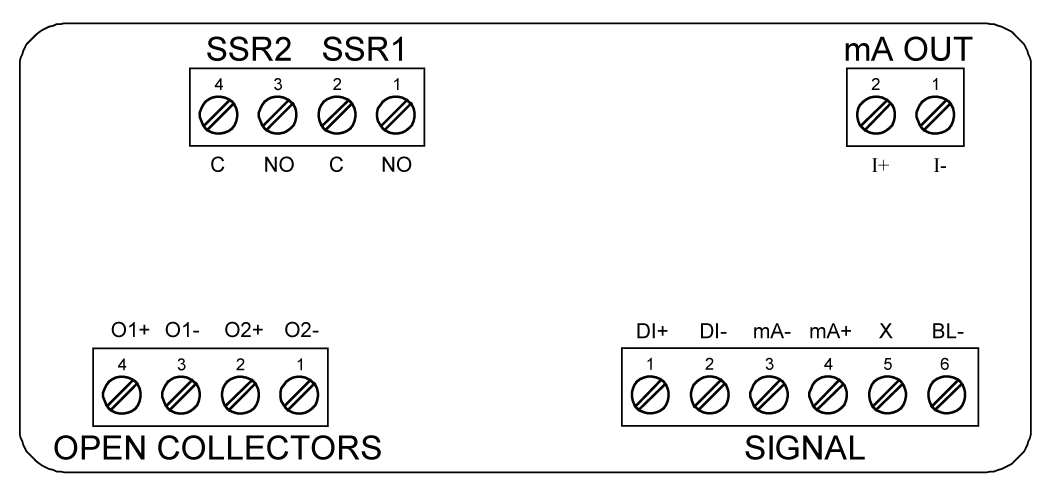

Connections

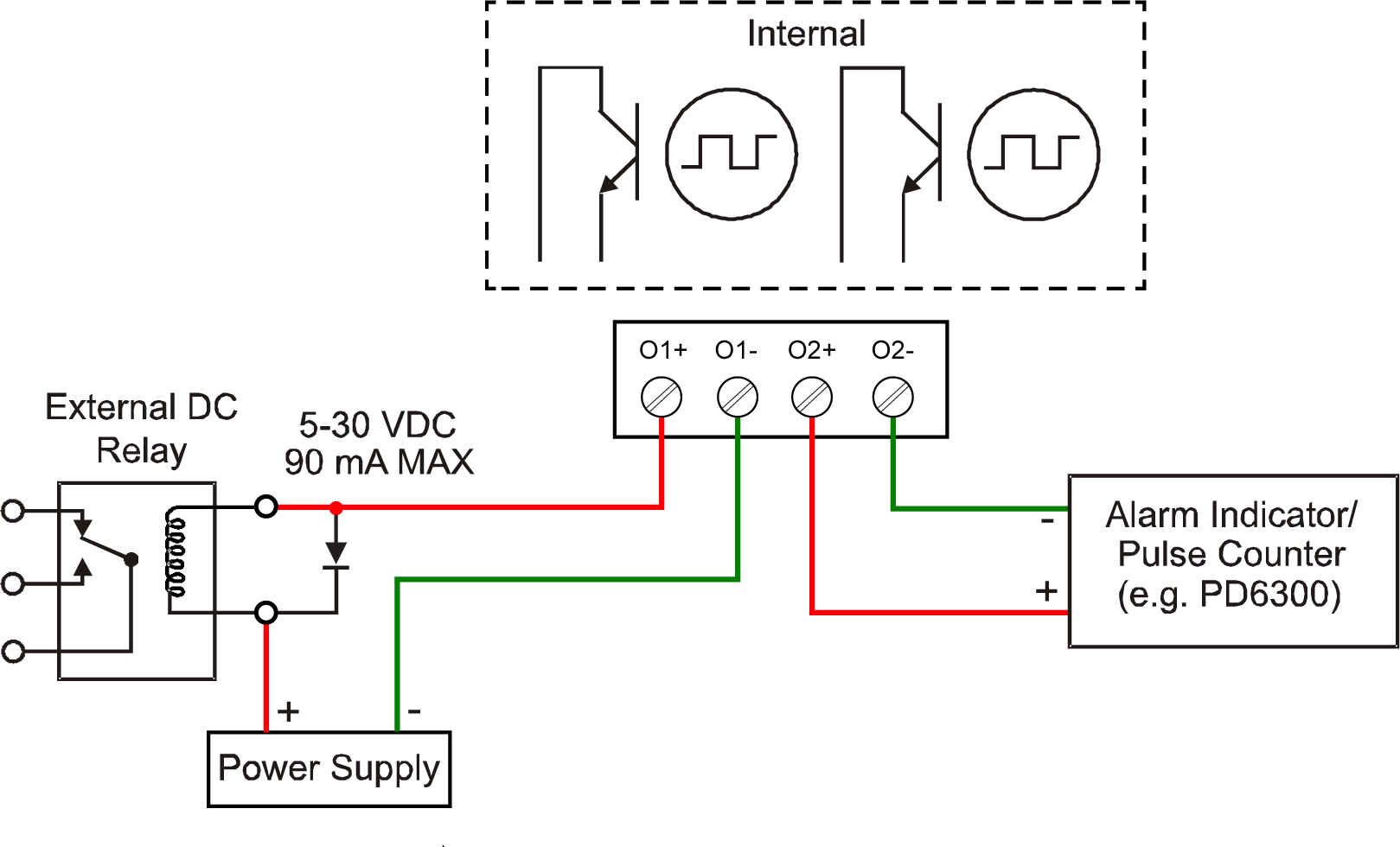

- (2) Open Collector Outputs Standard (150 mA max); Assignable to Pulse, Alarm, Timer, or Stopwatch

- Digital Input for Remote Operation of a Single Task

- (2) Optional Loop-Powered Solid-State Relays; Assignable to Alarm, Control, Timer, or Stopwatch

- Optional Isolated 4-20 mA Analog Output

Display Features

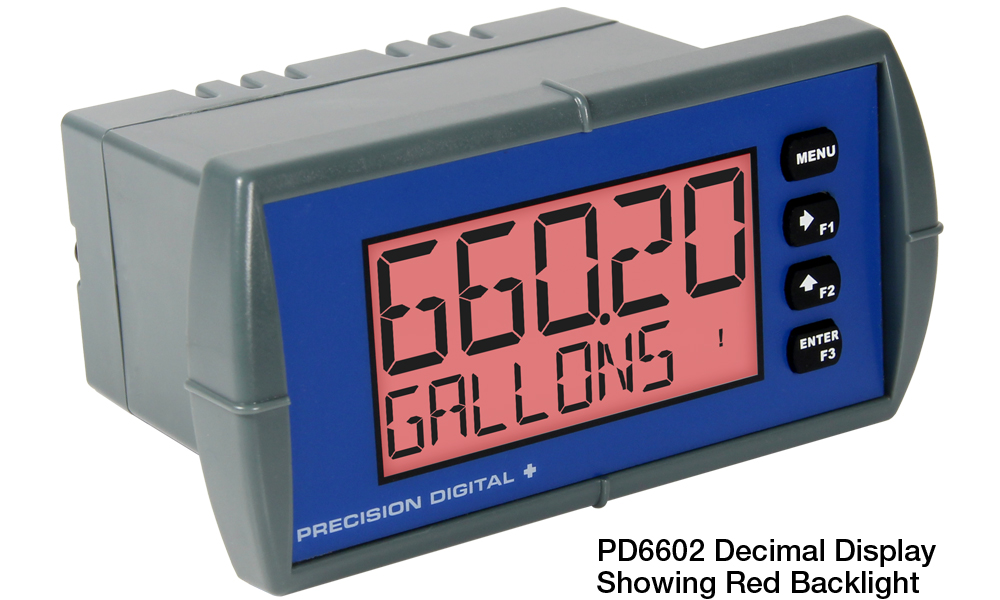

PD6602 Process Meter with Decimal Display

PD6603 Feet & Inches Level Meter with Bargraph

PD6604 Process Meter with Decimal Display & Bargraph

Commas Make it Easy to Read Big Numbers

The bottom display is set to show a comma separating the thousands and millions place by default if a numeric value is being displayed. This feature can be disabled or enabled using the Comma menu.

Dual-Line Display with PV/Units/Tag/Bargraph

One of the most common configurations of these instruments is displaying the process variable on the top line and units and a tag toggling on the bottom line with a bargraph for additional clarity. To help users get a quick understanding of where their process is at, certain Loop Leader models are available with a 20-segment bargraph. This bargraph also includes a numeric value of the percentage the bargraph represents.

Red, Flashing Display When Alarms Occur

When an alarm occurs, the display can be programmed to turn red, flash, and display an alarm indicator (!) (Alarm indicator symbol not available on bargraph models). In addition, a unique custom alarm message for each of the two relays and two open collectors can be displayed on the bottom display. These features can be activated even if no relay or open collector is connected.

Backlight Turns Red on Alarm

The loop-powered backlight is standard on all Loop Leader meters. It provides optimum visibility in any lighting condition and it can be programmed to turn red for alarm conditions. The backlight may be enabled or disabled using the Backlight menu. The backlight is enabled by default (input must be wired appropriately for the backlight to function).

Bargraph Provides Quick Understanding

To help users get a quick understanding of where their process is at, certain Loop Leader models are available with a 20-segment bargraph. This bargraph also includes a numeric value of the percentage the bargraph represents. The bargraph can be programmed to represent the percent of PV1 or PV2 or it can be scaled to any range within the scale.

Feet & Inches Display with Bargraph

There are Loop Leader models available for users that prefer to see their level displayed in feet & inches instead of decimal format. These versions can display level to 999FT 11IN & 15/16 on the top line. The bottom line can toggle between a tag and units or if dual scale mode is used, can display the input in a different scale such as volume.

The following graphic shows a PD6603 displaying level in feet & inches with bargraph. The bottom display toggles between tag (Tank 12), Volume (62,346), and Units (Gallons).

Dual-Scale Display Feature

Users can use the Loop Leader’s dual-scale feature when they want to show the same input in two different scales. For instance, the image above shows an application where the Loop Leader displays the input in feet and gallons.

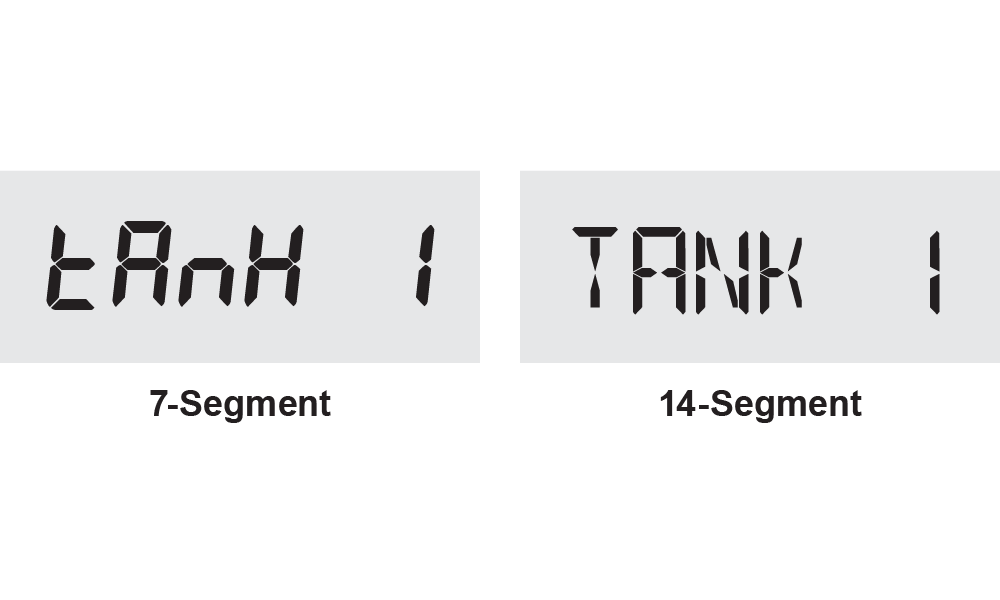

14-Segment Characters

Notice how much better letters like “T”, “N” and “K” appear as 14-segment characters on the bottom display vs. 7-segment characters found on other meters.

Max/Min Display

The max & min readings (peak & valley) reached by the process can be displayed either continuously or momentarily.

- Display momentarily by pressing the F1 function key (default) or assigning to any of the other function keys or to the digital input in the User menu. Press Enter to lock/unlock max/min display.

- Display continuously by assigning either display line to max/min through the Display menu.

Any of the F1-F3 function keys (buttons) and the digital input can be programmed to reset the max & min readings.

Predefined and Custom Units

The meter has six available preprogrammed unit classes, volume, height, temperature, pressure, weight, and rate. When the desired unit class or unit of measure within a class is not available, a custom unit may be programmed by using the (CUSTOM) menu.

Change Between Units

It is possible to change the display units within the selected unit class without the need to re-scale the meter. When selecting a new unit from within the DISPLAY menu (e.g. changing from gallons (GAL) to liters (L), the meter will automatically convert the display values to display the new unit. If entering a custom unit (CUSTM), a custom conversion factor will need to be entered.

Tare

The tare function zeroes out the display. In the case of scale weight, tare is used to eliminate container weight and provide net weight readings. The captured tare may be reset manually with any function key or digital input.

Outputs

Loop Leaders come with two open collector outputs as standard and two solid-state relays and 4-20 mA output as options. The open collector outputs and relays generally operate in the same manner, with the major exception being the open collectors are not available for pump alternation and the relays are not available with pulse features. The open collectors and relays can be controlled either automatically or manually. The alarm status (with a unique flashing red message for each of the two relays and open collectors) will show on the display even with no output wired.

Two Open Collector Outputs

The meter is equipped with two NPN open collector outputs that may be set up for pulse outputs, alarms, timed pulses, stopwatch on/off, or disabled. Pulse outputs can be set to transmit the PV value (PV1 or PV2 if meter is in dual-scale mode). Output 2 may be used to generate a quadrature output based on the other open collector output. An output test mode is also selectable to generate pulses at a constant programmable frequency.

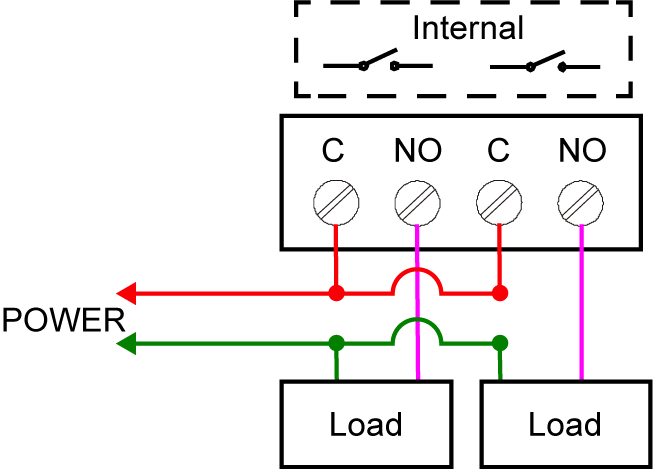

Two Optional Solid-State Relays

The meter is optionally equipped with two solid-state relays that may be set up for alarms, timer, stopwatch on/off, or pump alternation. The relays are rated at 250 VAC/DC @ 1 A for resistive loads and 75 VA @ 0.6 A, 250 VAC/DC max (Safe Area only) for inductive loads. Alarms are available based on the PV value or the digital input.

Optional Isolated 4-20 mA Output

The isolated analog output signal can be configured to represent the process variable (PV1, PV2, or retransmit). While the output is nominally 4-20 mA, the signal will accurately accommodate under- and over-ranges from 1 to 23 mA. The output can be reverse scaled such that the meter’s high calibration value outputs 4 mA and the meter’s low calibration outputs 20 mA.

Loop-Powered Relay Alarm Trip

The two solid-state relays can be used as a loop-powered relay alarm trip in general purpose areas. The Loop Leader’s two relays can be programmed for two different kinds of latching operation: Reset via momentary contact closure at any time or reset via momentary contact closure only after the alarm has cleared. And the meter’s display can be programmed to turn red and flash a unique custom alarm message for each relay – something not found on most loop-powered alarm trips.

Resetting the Open Collectors and Relays

The open collectors and relays (alarms) may be programmed to reset in the following ways:

- Automatic (AUTO): Alarm will reset automatically once the alarm condition has cleared.

- Automatic/Manual (AUTO.MAN): Alarm will reset automatically once the alarm condition has cleared but can also be reset using the Enter button (or whichever function key is set to acknowledge) at any time.

- Latching (LATCH): Alarm must be reset manually and can be done so at any time. Press the Enter (ACK) button at any time to clear the alarm.

- Latching with Reset after Cleared (L-CLEAR): Alarm must be reset manually and can only be done so after the alarm condition has cleared. Press the Enter (ACK) button after the alarm condition has cleared to reset the alarm.

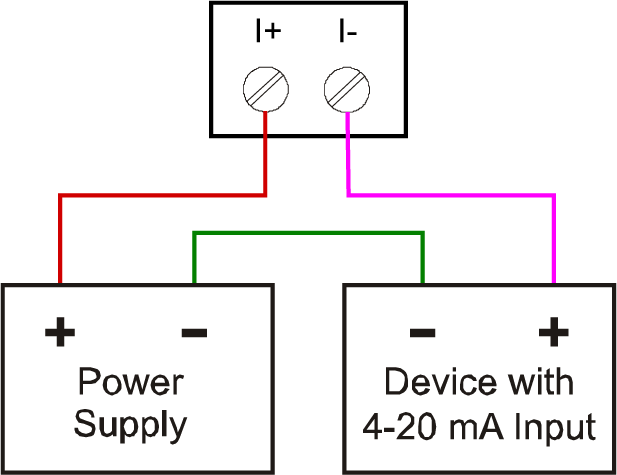

Loop-Powered Isolator

The Loop Leader can be used as a loop-powered isolator for the 4-20 mA signal with the added benefit of a digital readout to display the process variable.

Timer Function

Timers are used in everyday life; one of the most common examples is the microwave oven. Industrial timers are used in process control applications where certain events or actions need to be controlled by time. Examples include automatic batch control applications, where the relay needs to be energized for a specific length of time.

The timer fuction is available on the open collector and relay outputs; which means that you can have up to four timers per meter. The start and stop actions can be triggered from the setup menu or by the function keys and digital input. The meter can be setup to display the off/on timer count down.

There are two modes of operation:

- Continuous Timer (Interval)

At the start of the timer the output is off and turns on after the Off Delay elapses. The output remains on for the duration of the On Time. The cycle repeats until the user stops the timer either from the menu or a function key. - One-Shot Timer

At the start of the timer the output is off and turns on after the Off Delay elapses. The output remains on for the duration of the On Time. The timer stops and the cycle does not repeat.

- A sensor detects the bottle is in place and triggers the digital input to start the timer

- The timer output controls the filling pump

- The On Time is set according to the time needed to fill the bottle

Pump Control

Loop Leaders, when ordered with the two solid-state relays, have several features that make them ideal for simple duplex pump control. The relays can be programmed to alternate the pumps based on level and runtime thus ensuring even wear on both pumps. If the level remains constant (within on/off points), alternation is based on runtime. If the level cycles the on/off points, alternation is based on level and runtime. If the runtime is set to 0, alternation is based on level. The meter also keeps track of runtime for both pumps and the number of times they have cycled.

The meter can display pump runtime for both pumps

The meter can display pump runtime for both pumps The meter can display the number of times the relays have cycled

The meter can display the number of times the relays have cycledIn addition to the two solid-state relays for controlling pumps, the meter’s two open collectors could be used to indicate high or low level alarm conditions.

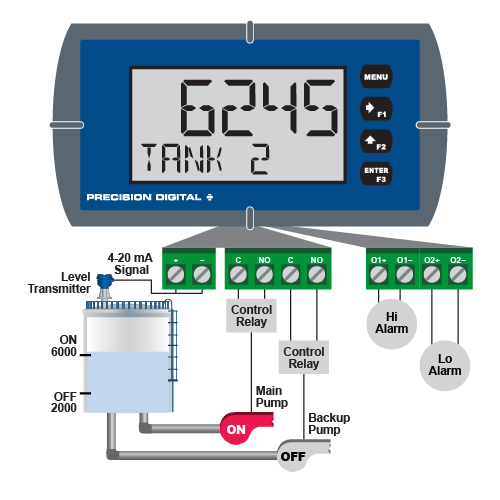

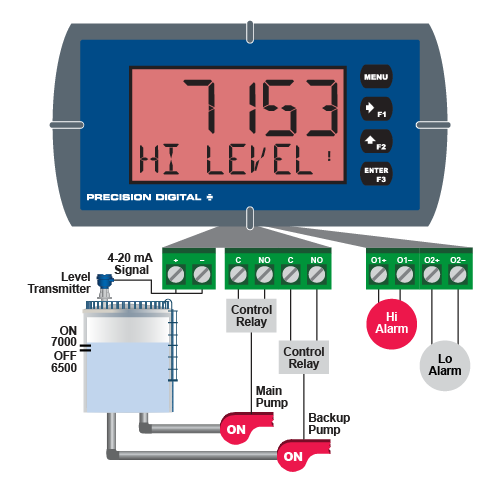

Pump Alternation Application

The Loop Leader can be used as a pump controller to alternate two pumps and provide high and low level alarm indication. The pumps can be programmed to alternate on level and runtime and the meter can display the pump runtimes and the number of times they have cycled.

Pump Control with Alternation & Alarm Example

The following is a typical application where the relays and open collectors are used for pump alternation and high/low level alarm.

| Relay | On Point | Off Point | Fucntion |

| 1 | 7,000 | 2,000 | Controls backup pump |

| 2 | 6,000 | 2,000 | Controls main pump |

| Open Collector | On Point | Off Point | Fucntion |

| 1 | 7,000 | 6,500 | Trips high alarm |

| 2 | 1,000 | 1,500 | Trips low alarm |

Step 1

Relay #2 turns the main pump on at 6000 gallons and turns it off at 2000 gallons.

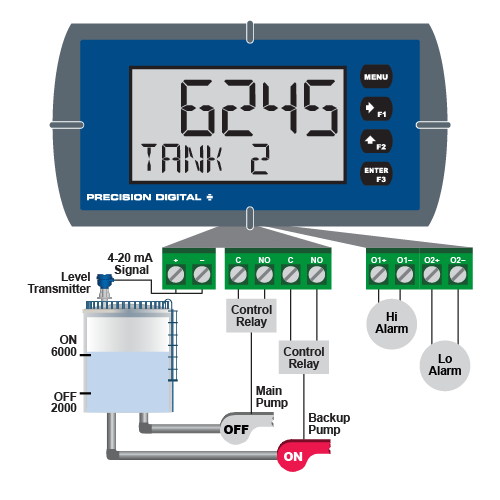

Step 2

With the Pump Alternation feature activated, the next time the level reaches 6000 gallons, relay #1 transfers and starts the backup pump.

Step 3

If the backup pump is not able to keep up, and the level reaches 7000 gallons, relay #2 transfers and starts the main pump as well. Open collector #1 trips the High Level Alarm, the display turns red and flashes “Hi Level” message, and (!) indicates an alarm condition. The High Level Alarm resets at 6500 gallons.

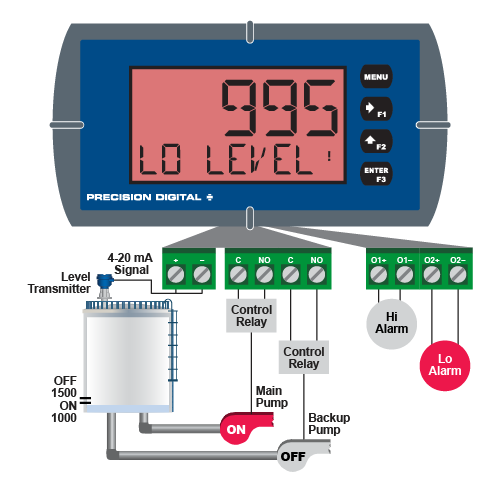

Step 4

Once the level has dropped below the reset points, both relays will turn off. If the Main Pump fails to turn off, open collector #2 trips the Low Level Alarm at 1000 gallons to warn against the pump running dry. The Low Level Alarm resets at 1500 gallons.

Input Signal Conditioning

To satisfy applications that require scaling in ways other than the usual 2-point linear method, the Loop Leader can also be scaled for square root (differential pressure flow), programmable exponent (open channel flow) or round horizontal tank volume calculation.

For existing processes that require these linearization capabilities, one of the great benefits of loop-powered meters is that they get their power directly from the 4-20 mA loop and thus require no additional wiring. All a user has to do is break the existing loop and wire in the meter. For this reason, loop-powered meters are very easy to add to existing applications such differential pressure flow, open channel flow, or round horizontal tank volume calculation.

Round Horizontal Tank Volume Calculation

This function automatically calculates the volume in a round horizontal tank with flat ends.

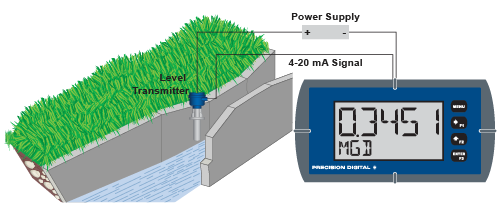

Programmable Exponent Linearization

The programmable exponent can be used to linearize the signal from level transmitters in open-channel flow applications using weirs and flumes.

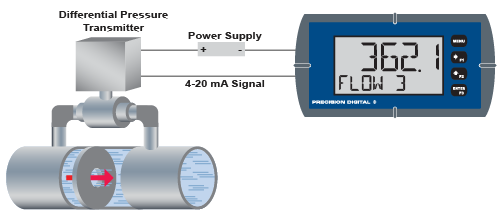

Square Root Linearization

The square root function can be used to linearize the signal from a differential pressure transmitter and display flow rate in engineering units. These meters will display flow rate only. To display both flow rate and total use the PD6622 or PD6624.

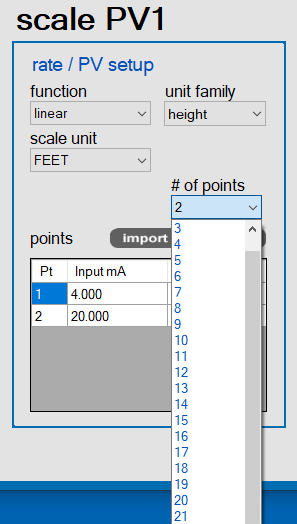

Multi-Point Linearization

Meters are set up at the factory for linear function with 2-point linearization. Up to 32 linearization points can be selected for the scaled value under the linear function. Multi-point linearization can be used to linearize the input so the meter can display volume from non-linear tanks or to convert level to flow using weirs and flumes with complex equations.

MeterView XL software makes it easy to program up to 32 points.

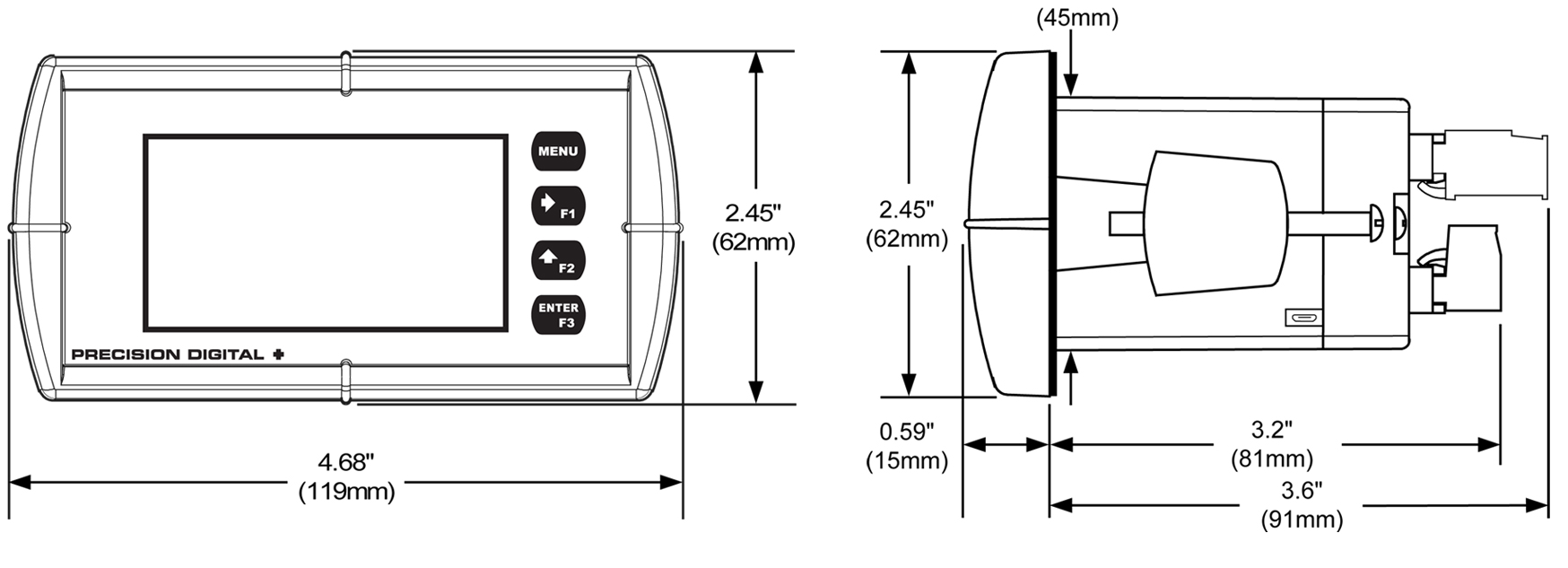

Physical Features

The Loop Leader is designed for ease-of-use in industrial applications. Considerations include a NEMA 4X front panel, wide operating temperature range, removable screw terminal connectors, snap in place mounting brackets, forgiving panel cutout requirement, and UL Listing for electrical safety. All of these features are backed by a 3-year warranty.

Type 4X / NEMA 4X Front Panel

Not only does the Loop Leader’s front panel UL Type 4X approval indicate it is waterproof, it also indicates it is rugged. Part of the UL Type 4X test is to drop a 2 inch, 1 lb solid stainless steel ball from 4 feet on top of the meter’s faceplate.

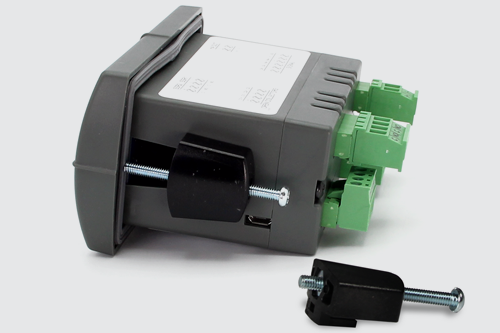

Removable Screw Terminal Connectors

Industrial applications require screw terminal connections for easy field wiring and the Loop Leader goes one step further in convenience by making them removable also.

Forgiving Panel Cutout Requirement

The Loop Leader’s bezel has been oversized to allow for not perfectly executed panel cutouts where NEMA 4X seal is not required.

Wide Operating Temperature Range

The Loop Leader can operate from -40 to 75°C (-40 to 167°F). This means it can be installed in a wide variety of indoor and outdoor industrial applications. And over this range, the Loop Leader will drift no more than 0.003% of calibrated span/°C from -40 to 75°C ambient.

Secured-in-Place Rugged Mounting Brackets

If you’re installing the Loop Leader outdoors in the hot or cold weather, the last thing you want to do is fumble around with mounting brackets that don’t stay in place. The Loop Leader’s mounting brackets can be easily secured into place and then screwed down to the panel. These brackets are rugged so they can be tightened to the panel to provide a solid NEMA 4X seal.

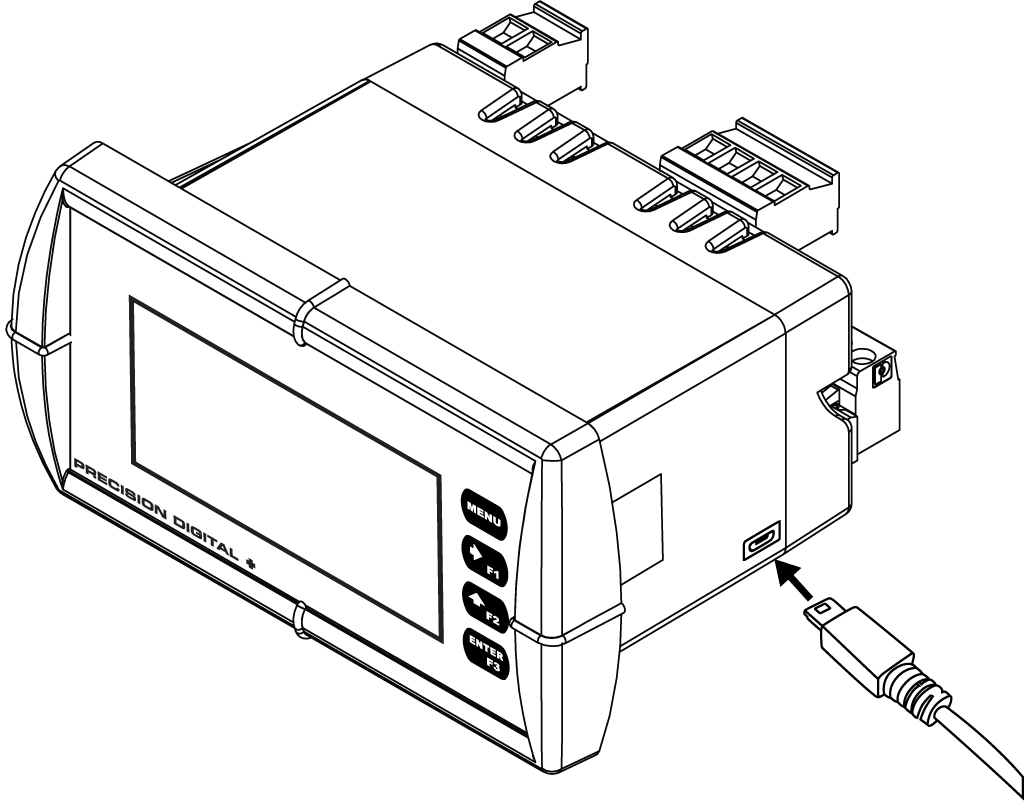

USB Port

A USB port located on the side of the meter allows it to be connected to a PC for use with free MeterView XL software. The meter is powered by the USB connection during programming, if a 4-20 mA loop is not connected.

Operational Features

There are two ways the user can interact with the Loop Leader to perform a variety of useful functions: programmable function keys and the digital input.

Programmable Function Keys

The three front panel buttons labeled F1, F2, and F3 can be programmed as function keys to perform a variety of meter functions simply by pressing the button. These include operation of the tare function, resetting the tare, resetting the meter’s relays or open collectors, starting and stopping timers, and displaying max/min values. The default settings for the function keys are:

| Button | Description (Default Settings) |

| Press to display max/min readings. |

| Press to reset max/min readings. |

| Press to acknowledge all manually resettable relays or open collectors. Press to lock/unlock the display value after pressing the F1 key. |

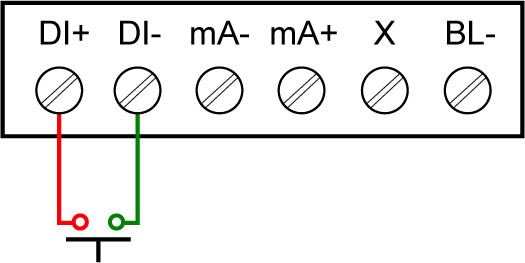

On-Board Digital Input

A digital input is standard on the meter. This digital input is programmed identically to the function keys. The input is triggered with a contact closure between DI+ and DI-, or with an active low signal. For a complete list of Digital Input settings, see the instruction manual.

Remote Operation of Meter

The meter is equipped with a digital input that can be programmed to perform various functions. Common uses for this digital input would be for resetting the meter’s relays or open collectors, starting and stopping timers, and displaying max/min values. For a complete list of Digital Input settings, see the instruction manual. The digital input could be connected to a PDA2361-R single button remote control station as illustrated in the following diagram.

For more information about control stations, please see PDA2360 Plastic Control Stations.