Few things are as ubiquitous in the process control industry as the need to measure the level of a process material in a container. Whether that material is water, waste water, petroleum, sugar, or any other form of liquid or solid, level measurement accuracy can be a determining factor in both profit margins and safety.

On December 11th 2005, malfunctioning level gauges were partially responsible for a massive explosion at the Hertfordshire Oil Storage Terminal in Hertfordshire, England. According to the Health and Safety Executive that investigated the blast, "the tank was full, but gauges and safety devices did not work."1 A high level switch that should have detected the petrol level and cut off flow to the tank failed to operate and workers didn't notice that the tank was overflowing2. This resulted in a 32-hour inferno which injured 43 people and left many families homeless.

Because of the importance of accurate level measurement and the myriad of different process materials requiring level measurement, an almost equal number of unique methods for detecting level have been developed. Selecting the correct level measurement technique for a particular application can seem like a daunting task in the face of so many options. All level measurement systems rely upon certain characteristics of the process material, such as density, capacitance, temperature, etc., and each has its own particular advantages and disadvantages. It is important to understand the fundamental mechanics of the level measurement technologies being considered in order to correctly specify the appropriate method (or methods in the case of redundant systems) for the application.

Categorizing Level Measurement Technologies

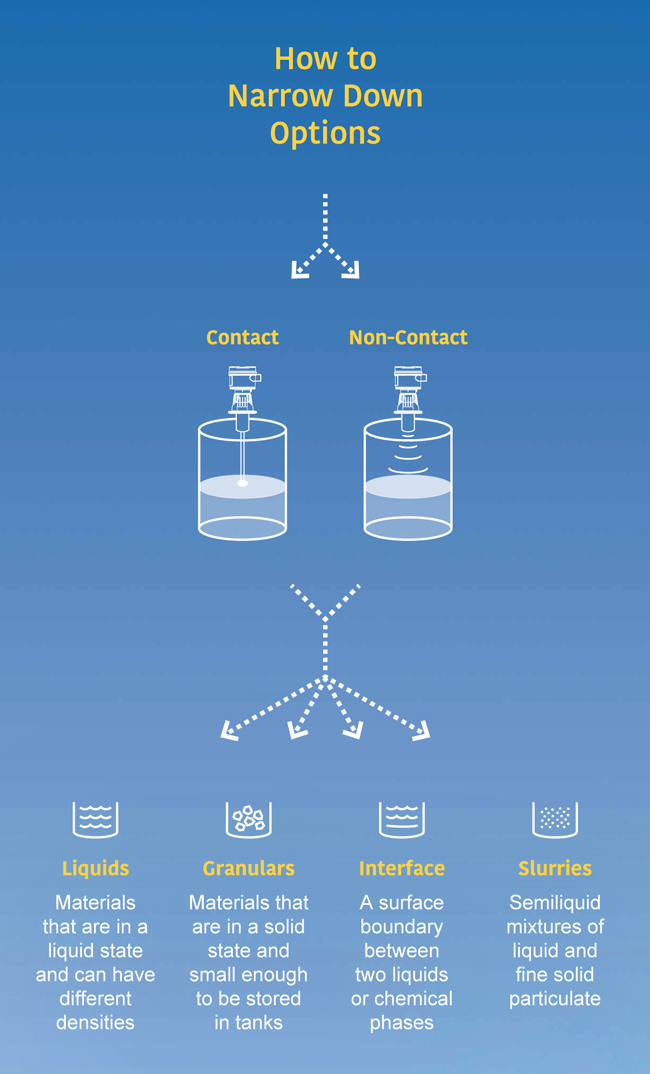

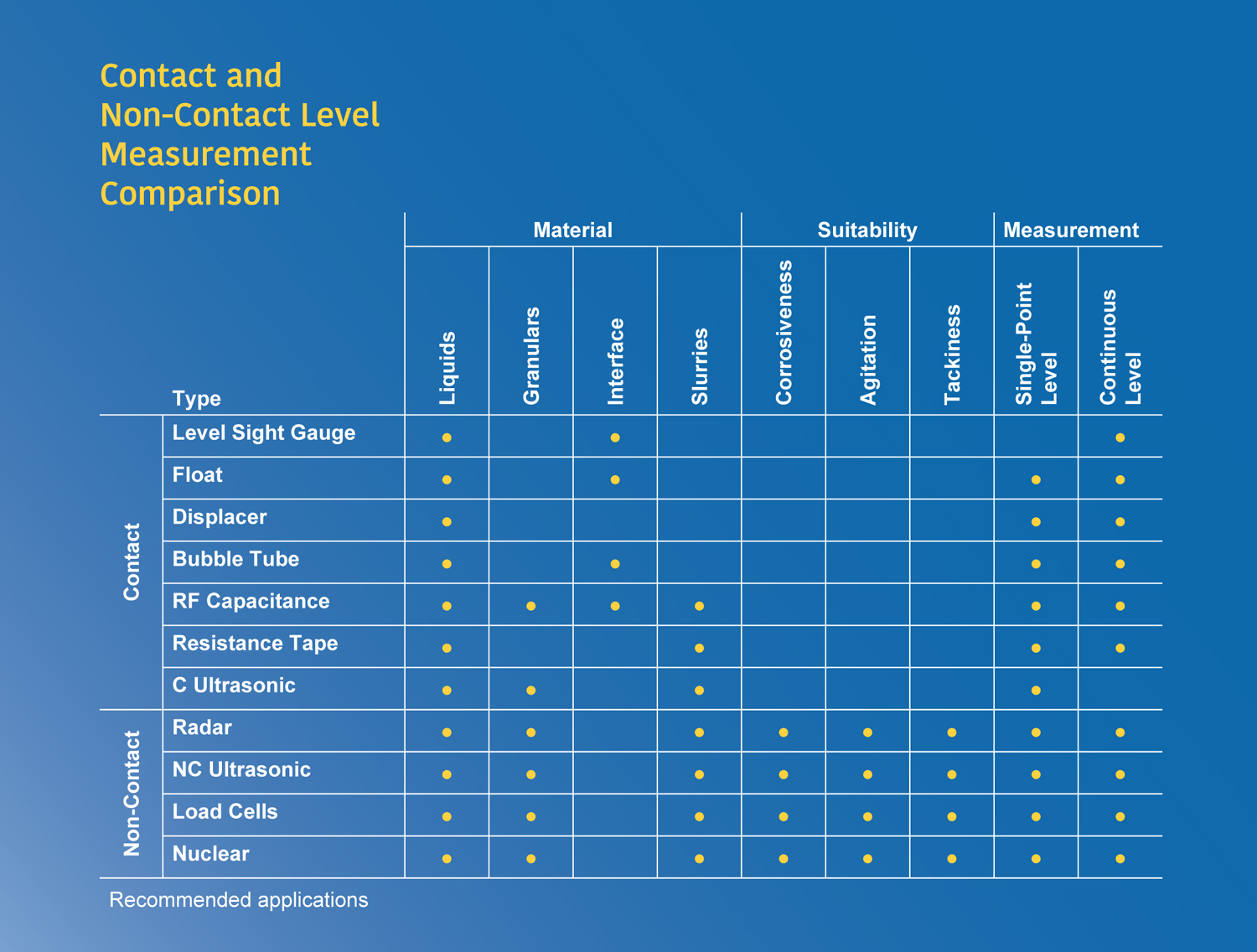

A good way to reduce the number of level measurement options is to categorize them into two broad categories: contact and non-contact. Then you can filter choices by the type of material they can measure.

The characteristics of the process material being measured, such as tank size and shape, the pressure and temperature that the process requires, amount of material agitation, available power, etc., must be taken into accountwhen determining if a contact or noncontact approach is the right option. One must consider whether the material is corrosive or tacky and could possibly cause damage to the measuring device, whether it is volatile and a contact sensor might create a safety hazard, whether the agitation, temperature, or pressure of the process material could affect the reading of or damage the contact sensor, and any other troublesome possibility. On the other hand, non-contact solutions may be outside of the budgetary constraints of the project or not provide the necessary level of precision.

Process materials that need level measurement can generally be classified as liquids, granular solids, slurries, and interfaces. Liquids vary greatly in density and can be under a wide range of pressures and temperatures, depending on the process. These factors influence the types of level sensors that can be used. Interface level, or the point at which two liquids of different densities meet,,requires special consideration over typical liquid level measurement. A lot of the sensor technology that can be successfully employed in measuring liquid will be unwieldy or simply unusable when measuring granules such as loam and stone dust, or slurries such as cement. For these reasons, it is important to understand the type of process material (at all stages of the process) you are dealing with prior to looking into level measurement options.

An Overview of Level Measurement Technologies

Because for the sheer number of level measurement technologies, the following overview is not meant to be all-inclusive nor is it meant to cover every intricacy of the technology in question. It is meant instead to give a very high-level synopsis of some of the different types of technology available and how each functions as a measurement device. More detailed information regarding a specific measurement device can be found in the manufacturer's documentation and should always be consulted prior to purchase as every device uses level measurement methodology differently. That being said, a broad understanding of how each technology category is meant to function will give you a proper head start when specifying level measurement sensors.

Contact Sensors

The first type of level measurement device to be considered here is also the simplest. A level sight gauge typically consists of a tube connected at openings near the top and bottom of the tank. The tube has a transparent face so an operator can see the level of the process material. This is technically a non-contact measurement because there is no sensor making contact with the process material. However, many of the same concerns about contact sensors should be taken into account, such as agitation, corrosiveness, tackiness, temperature, pressure, etc., which could damage or obscure the viewing area. Though this method of level measurement may be considered the most trustworthy because the material level can actually be seen by the operator, pressure or temperature differentials between the tank and the viewing area can have an effect on measurement accuracy3. When measuring an interface, the top opening of the gauge must be submerged at the level of the top liquid and the bottom opening must be at the level of the denser liquid or else the level measurement will be incorrect. Level sight gauges can only be used when measuring liquids, as granules and slurries cannot move fluidly through the gauge. There is also no way to incorporate any type of automation into the process using this type of measurement device.

Other devices, such as floats anddisplacers, rely on the material's specificgravity (density) to measure level. They often use a gauge similar to the sight level (a tube connected to the side of the tank towards the top and bottom). Magnetic floats, a specific type of float level sensor, typically rely on reed relays placed lengthwise within the tube. When the float passes these relays the magnetic field trips them. Therefore, the accuracy of such a sensor is limited by the number of reed relays placed in the gauge. Other float sensor types rely on the measurement of the extension and retraction of a connected cable. This type of sensor, in principle, requires no power to operate but is susceptible to failure from float jamming or clinging.

Displacers are dissimilar from float devices in that they are denser than the process fluid and suspended by a spring. They rely on Archimedes' Principle to detect changes in buoyancy force, which is equal to the weight of the displaced fluid, caused by a rise or fall in level. A sensor at the top of the gauge measures the change in apparent weight of the displacer body. The level measurement is therefore a product of the length of the displacer body covered by the process material and the specific gravity of the material4. Both displacers and floats require much of the same considerations as mentioned previously with level sight gauges and special considerations for interface measurement.

Bubble tube level measurement relies on the specific gravity of the process material as well. With this type of contact sensor, a tube is submerged into the process fluid and air or nitrogen is pumped through the opening, near the bottom of the tank. The resulting back pressure is proportional to the liquid level and density5. In instances where submerging a tube into the process liquid is impractical, air can be pumped in through an entry at the side of the tank. This type of sensor can only be used to measure the level of liquids. If the process liquid in which the tube is submerged remains at a constant level, any change in backpressure is due to a change in density or interface level, thus allowing for measurement of these variables6.

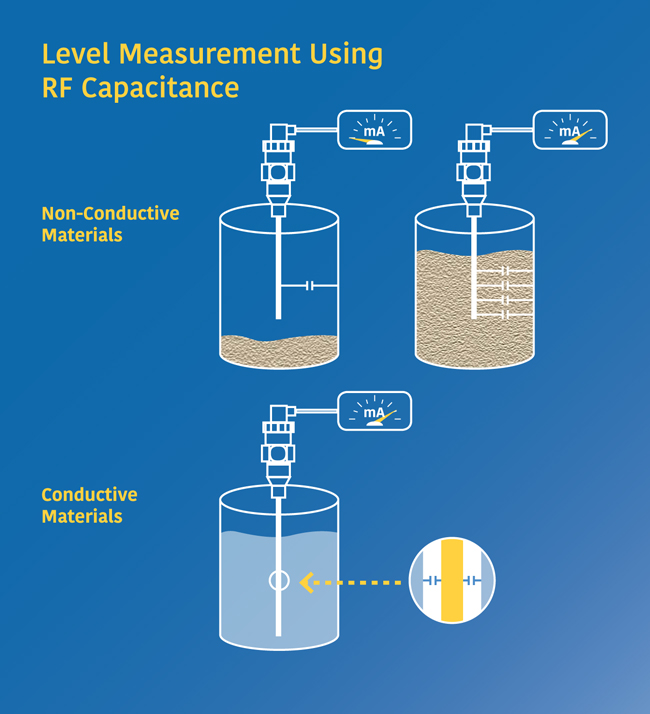

RF Capacitance level sensors use the same operating principle as an electronic capacitor in order to gauge level. An electronic capacitor consists of two conductive metal plates separated by some kind of insulating material. Capacitance is the measurement of the amount of energy a capacitor can store. Using a method that is very similar to that of an electronic capacitor, the capacitance of a process material can also be measured and then correlated to the level. If measuring a non-conductive material, that material is used as the insulator part of the capacitor and the tank wall acts as the second conductive plate; if measuring a conductive material, the probe body is shielded with an insulator and the material acts as the other conductive plate7. In either case, a rise in the level will correlate with an increase in the measured capacitance (over that of air). This technology can be used for either point-measurement level switches or continuous level measurement. Variations of this technique can be used to measure liquids, granular solids, slurries, and interface levels8.

The mechanical force of a process liquid can be used to measure level using what is known as resistance tape. Two wires, one attached to a voltage source and the other to a precision resistor, are contained within a shielded, flexible probe. Hydrostatic pressure pushes on the probe body and shorts out the submerged length of wire. The change in resistance is correlated with the level of the process liquid. These types of contact probes tend to be very delicate and changes in density can have a minor effect. They are typically used to measure liquids and slurries9.

Vibrating or ultrasonic level switches work under the principle that the sensor will vibrate at its resonant frequency when not submerged in process material. If the frequency is dampened, the material has reached the level of the switch. This technique works with liquids, slurries, and granules, although consideration should be made for coating or corrosive materials. Vibrating level switches will typically only be used for point level measurement, as opposed to continuous level measurement, and trigger high and/or low alarms. The sensors themselves tend to be fragile because of the level of precision necessary10.

Radar is a technology which was first extensively developed and deployed during the second World War as a means of detecting aircraft, ships, and other large objects. Since the technology was introduced to the civilian sector, many peacetime usages of the technology have been established, including level measurement. Radar typically works by emitting electromagnetic pulses in the direction of an object, waiting for that pulse to reflect off the object and return to the source, and measuring its time-of-flight. The distance between the pulse source and the object can be calculated as the product of one-half the time-of-flight and the speed of light. For use in level measurement, a radar transceiver is suspended from the top of the tank and measures the distance to the top of the process material. The overall length of the tank body can then be used to calculate the level. As a non-contact sensor, radar has the distinct advantage of not being affected by the process material's state, such as agitation, corrosiveness, tackiness, temperature, pressure, etc. Radar can be used to measure liquids, slurries, and granular solids. However, materials with high conductivity tend to be better candidate for radar level measurement because they reflect more of the emitted radio signal. As such, conductive materials other than the process material within the tank, such as agitators, can cause interference with the radar signal.

Non-contact ultrasonic level sensors use a very similar method as radar sensors to measure level. However, instead of using radio waves they use sound waves and the distance is calculated as the product of one-half the flight time and the speed of sound. Unlike the speed of light, the speed of sound is temperature dependent, so the temperature of the tank must also be measured and taken into account11. Like radar, they can also be used to measure liquids, slurries, and granular solids. Process materials that produce a stronger sonic reflection are more applicable to this type of measurement. Condensation, dust buildup, and presence of additional objects within the tank can all cause measurement inaccuracies12.

Load cells, sensors normally used to measure weight, can be used to gauge tank level. These sensors are attached to the support columns of a tank and measure the downward force applied on them by the mass of the container above. By taking into account the weight of the tank when empty and assuming that the tank has straight sides, any change in the weight measured by the load cell can be correlated with a change in level. Load cells can be used to detect the level of liquids, slurries, and granular solids, but require the process material to be of constant density. Load cells typically are not used to measure interface level.

Nuclear type level sensors use radioactive isotopes, typically either cobolt-60 or caesium-137, to emit gamma radiation into a storage container and sensors on the opposite side to measure the attenuation, or change in frequency modulation, of that radiation. Isotopes are atoms that have the same chemical behavior as one another but a different number of neutrons. Radioactive isotopes are those isotope variations which are unstable under normal conditions and decay into other elements. When these atoms decay, they emit three different kinds of radiation (alpha, beta, and gamma) which can be picked up and measured by special sensors. Gamma radiation is used for the purposes of level measurement because, of all three kinds, it is the best at penetrating materials13.

This technology can be used in both single-point and continuous level applications. In single-point measurement, such as high and low alarms, a sensor is typically installed parallel to the source of radiation on the opposite side of the tank and any change in frequency modulation over a certain threshold triggers an alarm. Since radiation is released from all directions from a radioactive element, continuous level measurement involves using sensors along the length of the tank on the opposite side. Using the attenuation detected through an empty tank as a baseline, any change detected by a sensor is attributed to the level being at or above that sensor. Though this technique is affected little by the physical state and properties of the material, it is typically only used when all other options have been exhausted due to the dangers and expense of using radioactive material and the stigma associated with it.

Summary

The technologies described here barely scratch the surface of those available to the industry (not to mention variations of these technologies). Due to the nearly countless number of process materials and conditions in all of the industries that require level measurement for their processes, an almost equal number of methods for measuring level have been devised. However, understanding the differences between and limiting factors attributed to contact and non-contact sensors, as well as the fundamental operating

principles of some of the more common level sensor technologies, should help when specifying what technique is best suited for a particular application. Instances of level measurement and control failure, such as the events that unfolded at the Hertfordshire Oil Storage Terminal, can lead to tragic and costly consequences that could have been avoided. A level perspective is vital to maintaining accurate process control and ensuring continuous safety.

by Simon Paonessa - Technical Writer, Precision Digital Corporation

References

- Buncefield tank 'was overflowing', BBC News, 9 May 2006, http://news.bbc.co.uk/2/hi/uk_news/4752819.stm

- How Buncefield fire unfolded, BBC News, 13 July 2006, http://news.bbc.co.uk/2/hi/4525504.stm

- Lipták, Béla G., et al., Instrument Engineers' Handbook, Fourth Edition, Volume One: Process Measurement and Analysis, CRC Press, 2003, 413

- Ibid., 465

- Ibid

- Foxboro, Bubble Tube Installations for Liquid Level, Density, and Interface Level Measurements, September 1988, http://resource.invensys.com/instrumentation/documentation/eib/mi/mi020328.pdf

- Magnetrol, Kotron® RF Capacitance, 2009, http://www.magnetrol.com/v2/pdf/MII/50-100.pdf

- Lipták, 430

- Lipták, 526

- Ibid., 413

- Magnetrol, Ultrasonic Non-Contact Transmitters, <us.magnetrol.com/Technologies_Individual.aspx?id=23

- Lipták, 412

- Ibid., 515