Quick & Easy Scale & Programming Methods

The Helios can be programmed either via the front panel push buttons or free, PC-based MeterView Pro software. MeterView Pro is resident on the Helios and is accessed by a provided USB cable, so it is by far the easiest way to program the Helios. The Helios can be calibrated either by applying a known signal or scaled by entering a desired value with the front panel buttons or MeterView Pro software. Most customers will use the scaling method because it is simpler and does not require a calibrated signal source. Selecting the input to be current or voltage is done with the front panel buttons or MeterView Pro software. Once programming is completed it can be locked with a password.

Free PC-Based MeterView Pro USB Programming Software & Cable

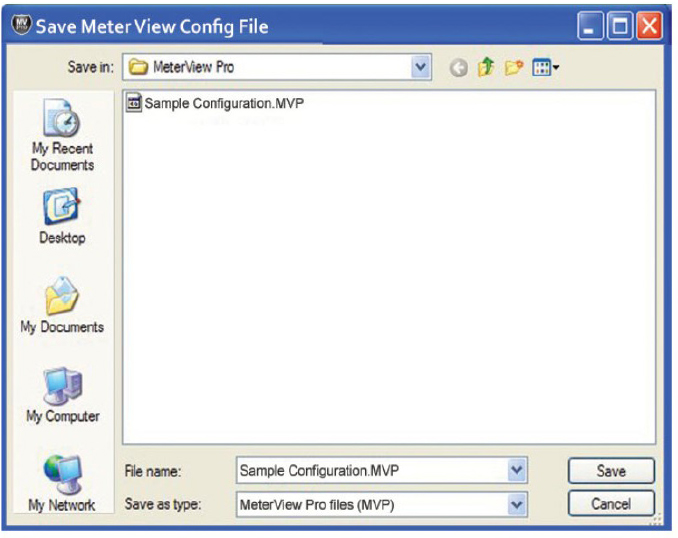

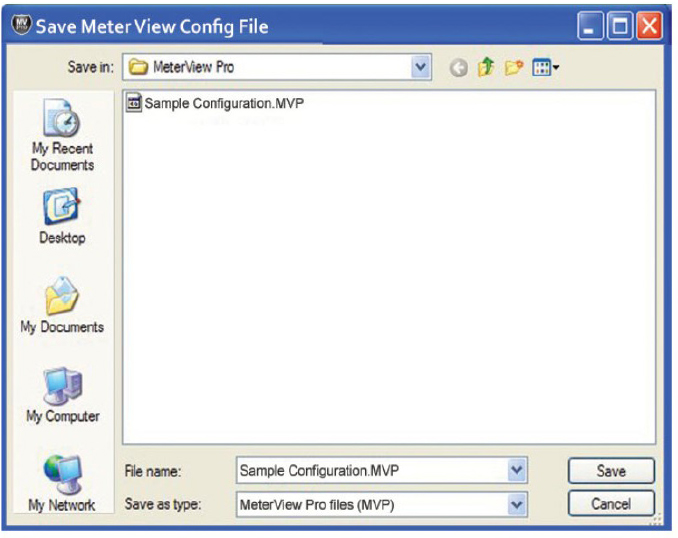

The Helios comes preloaded with free MeterView Pro programming software that connects and installs directly to your PC with a standard USB cable, also provided free with each instrument. This eliminates the need to insert CDs, install drivers, or download software from the internet. When you connect your Helios to your PC, MeterView Pro is downloaded to your PC, the software automatically selects the model you are programming, and you’re ready to start programming immediately. Further simplifying the programming process, the Helios can be powered from the USB port, so no need to apply external power while programming your meter. In addition to programming, the software will also allow you to monitor, and datalog a Helios using your PC. You can also generate and save programming files for later use.

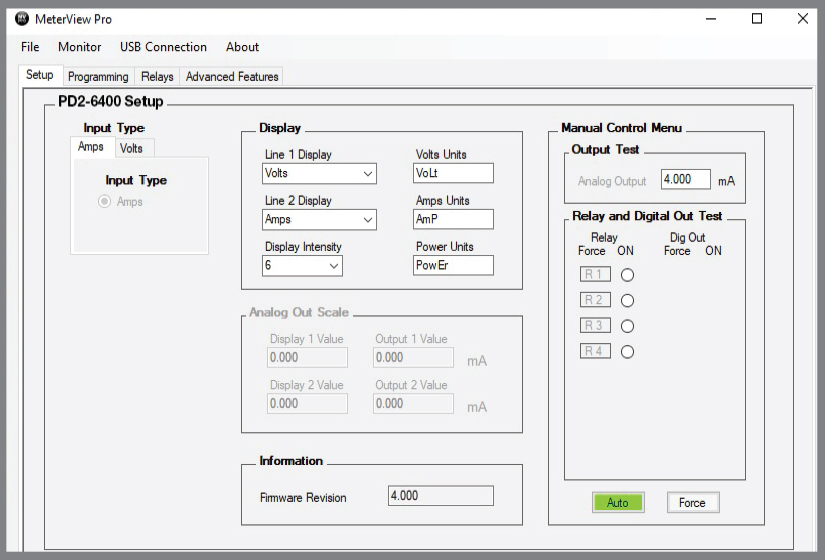

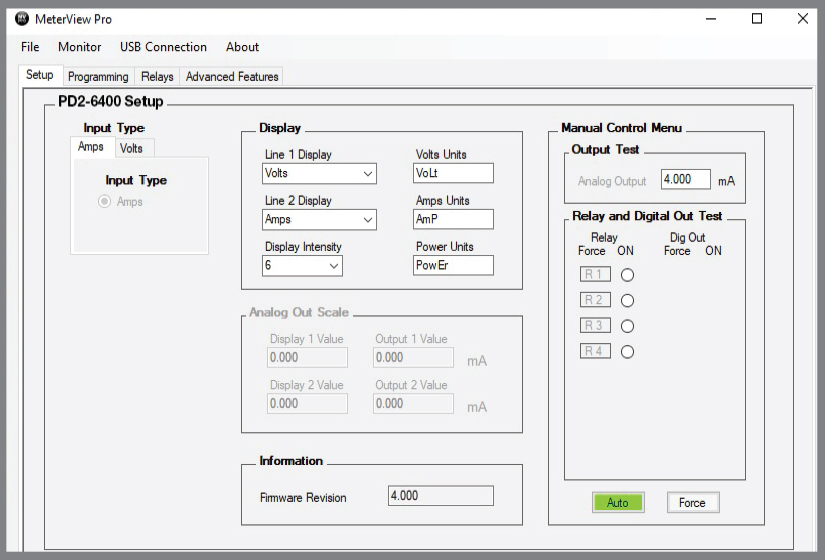

Setup Screen

- Select Voltage or Current Input

- Activate Dual-Scale (Level) Function

- Select Decimal Point

- Set Line 1 Display Parameters

- Set Line 2 Display Parameters

- Set Analog Output Values

- Enable Manual Control

- Test Relays & Digital Outputs

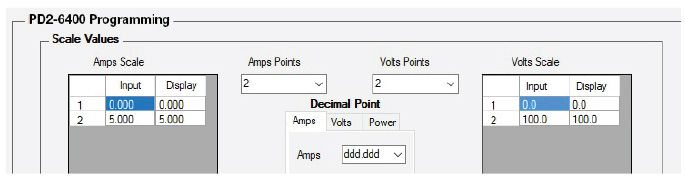

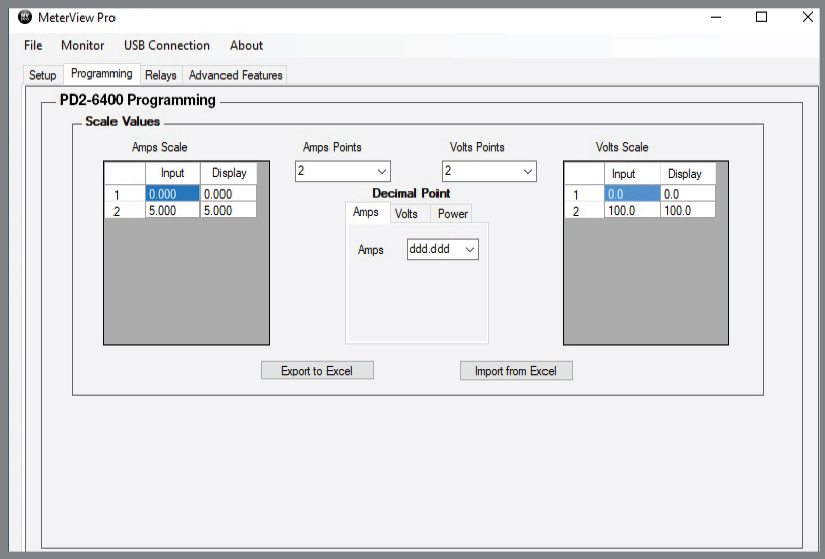

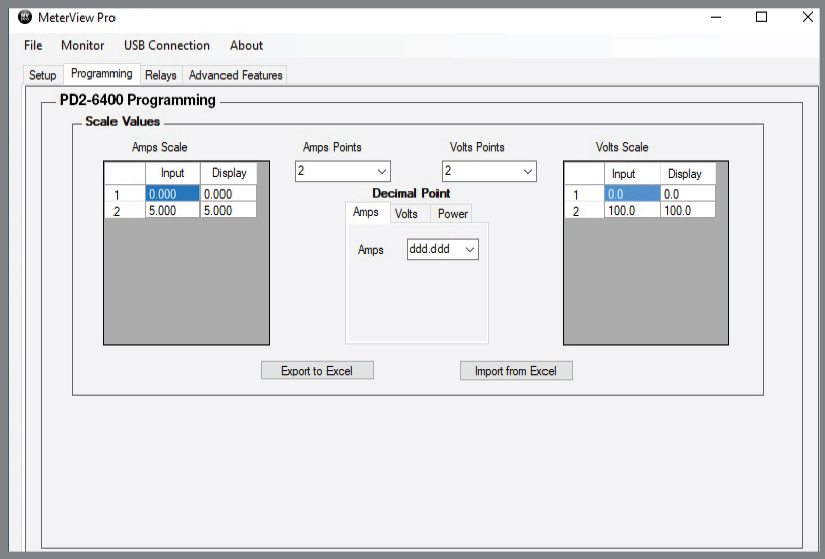

Programming Screen

- Set Scale Values

- Set the Number of Points (up to 32)

- Import from Excel

- Export to Excel

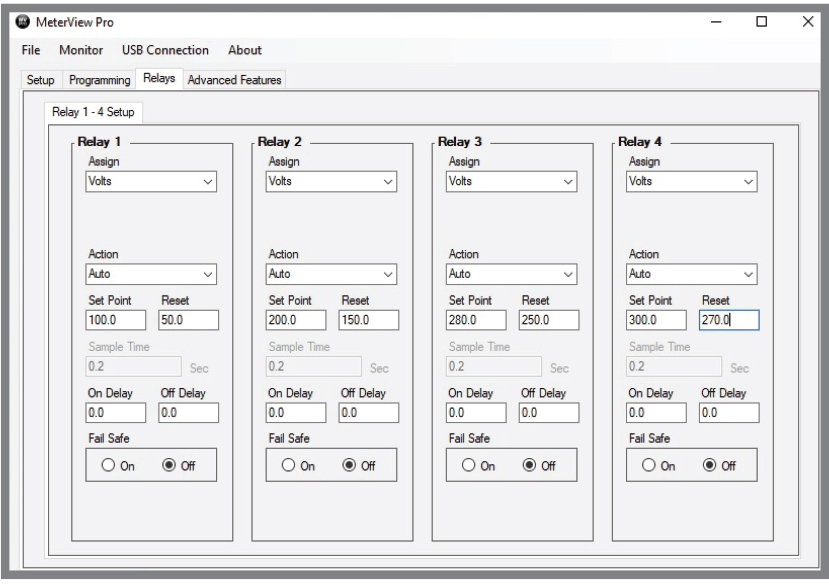

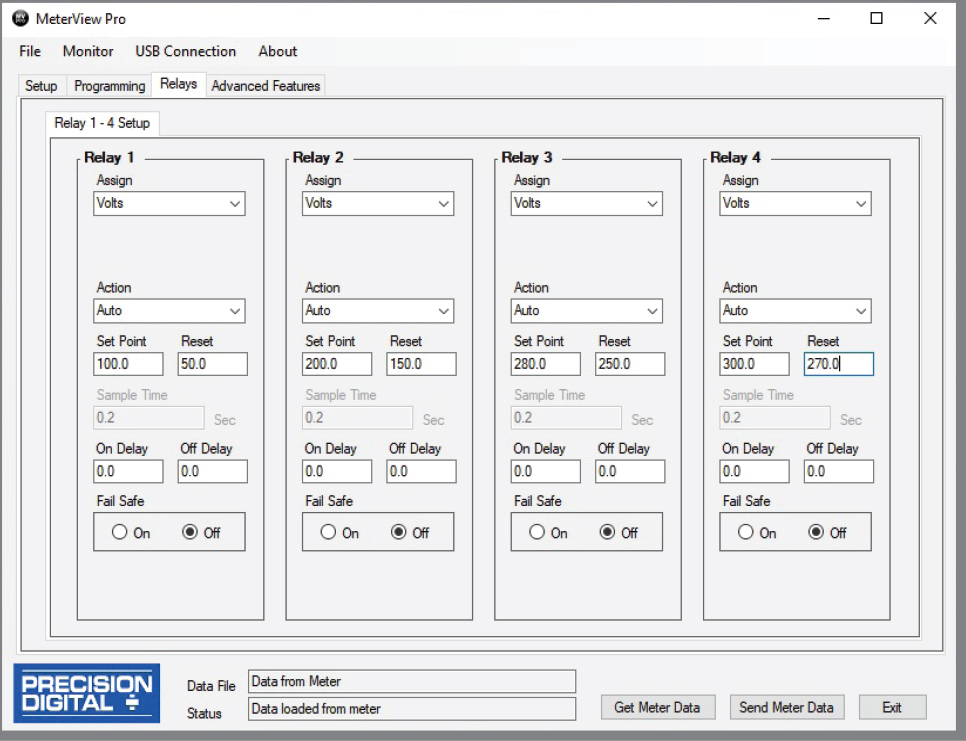

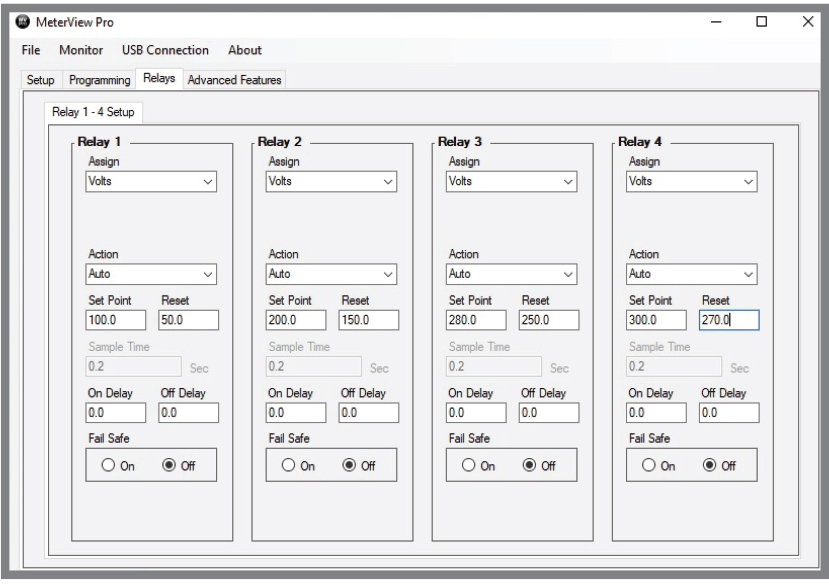

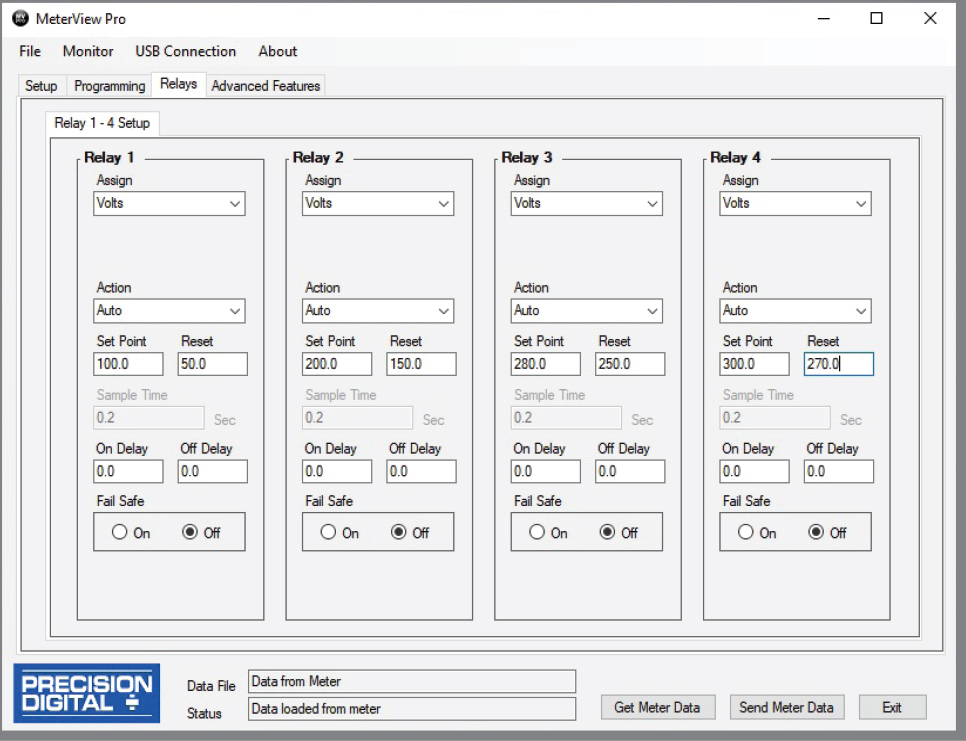

Relays Screen

- Greatly Simplifies Programming a Variety of Relay Features

- Set Relay Action

- Set Sampling Time

- Set Set & Reset Points

- Set On/Off Time Delays

- Set Fail Safe Operation

- Set Input Break Relay Action

Save/Open Configuration

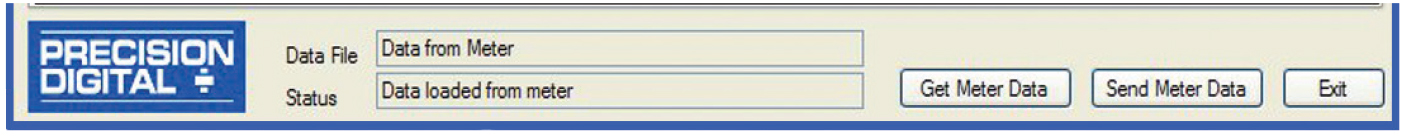

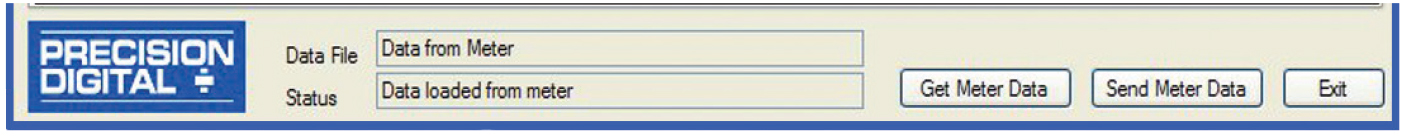

At the bottom of most MeterView screens are two tabs:

- Get Meter Data: This reads the programming of the meter that is currently connected to the PC.

- Send Meter Data: Clicking this button, sends current MeterView programming to the meter.

The configuration file can be sent, or retrieved, from the directory of your choice. This makes it very easy to program multiple meters with the same programming. It is also a great backup utility as well.

Specifications

System Requirements:

Microsoft® Windows® XP/Vista/7/8/10

Communications:

Onboard USB (firmware version 4.0 or higher),

RS-232 Adapter, or RS-485 Adapter

Meter Address: 1 - 247

Reports:

- Data logging: Save as CSV file format

- Configuration: Save as PDC file format or print configuration

Baud Rate: 300 - 19,200 bps

Configuration: One meter at a time

Protocol:Modbus RTU (requires Helios firmware version 4.0 or higher)

*Note: Windows® 32/64-bit operating systems

Password Protection

The Password menu is used for programming three levels of security to prevent unauthorized changes to the programmed parameter settings:

Pass 1: Allows use of function keys and digital inputs

Pass 2: Allows use of function keys, digital inputs and editing set/reset points

Pass 3: Restricts all programming, function keys, and digital inputs

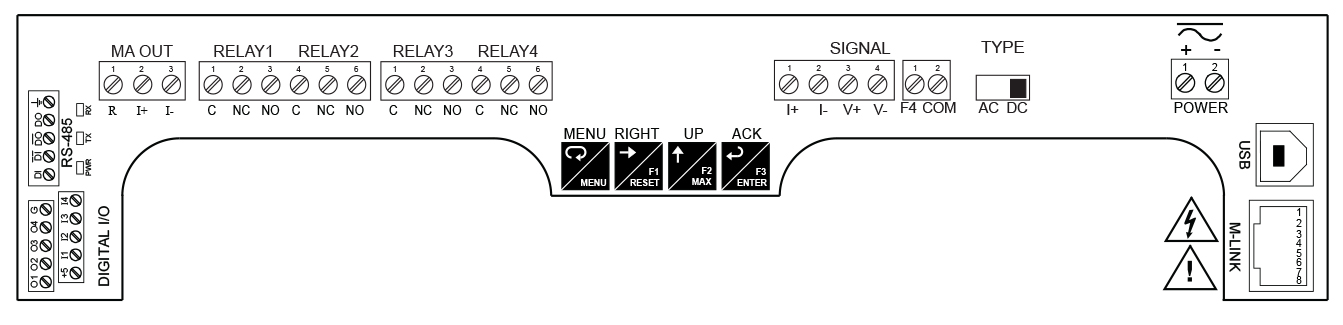

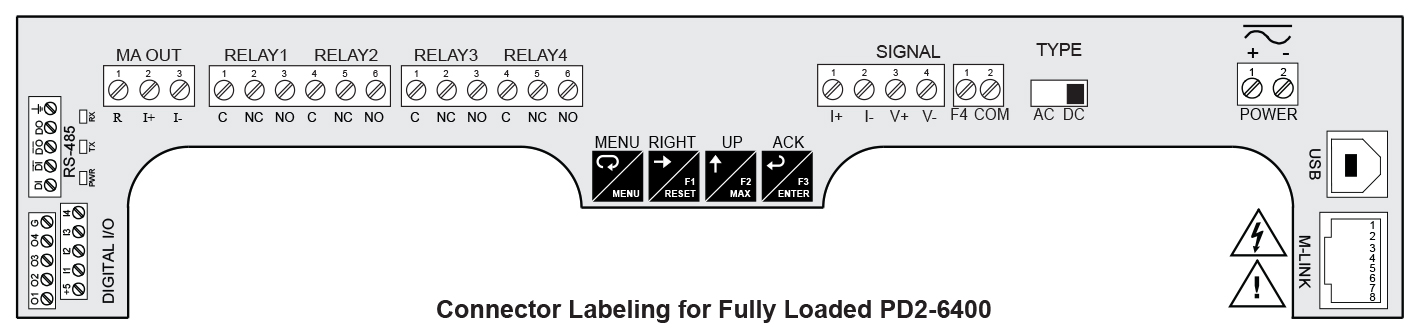

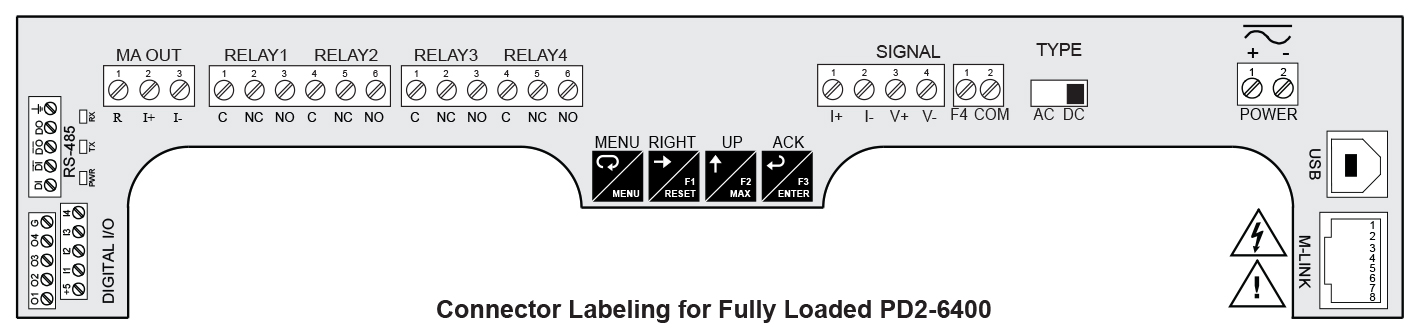

4-20 mA Output & Relay

4-20 mA Analog Output

The isolated analog output can be configured to represent the process variable (PV), maximum (peak) value, minimum (valley) value, the value for any of the eight relay set points, or Modbus input. While the output is nominally 4-20 mA, the signal will accurately accommodate under- and over-ranges from 1 to 23 mA.

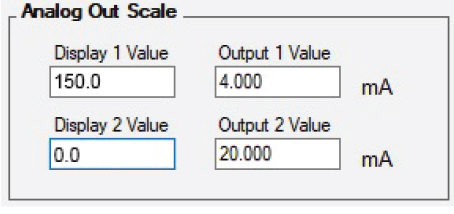

The 4-20 mA output can be reversed scaled such that 4 mA represents the high value and 20 mA represents the low value. For instance, a 4-20 mA output signal could be generated as the meter went from 100.0 to 0.0.

For applications where the input was linearized by the Helios, the 4-20 mA output will represent that linearized value.

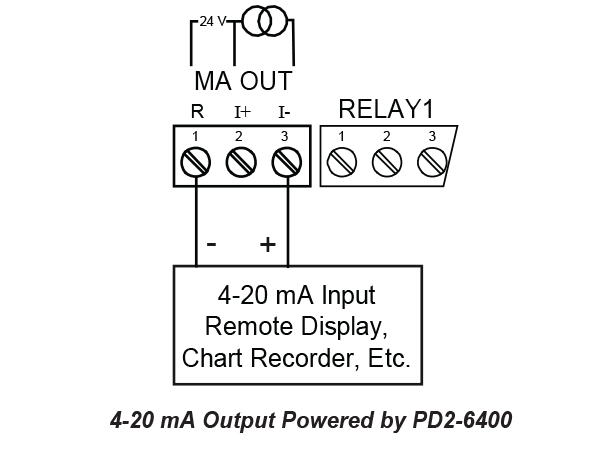

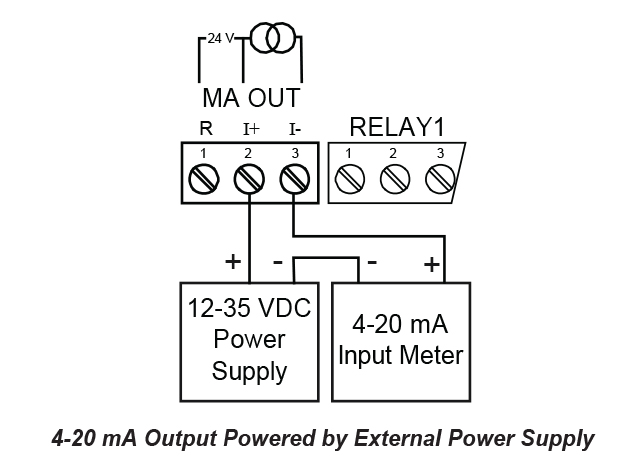

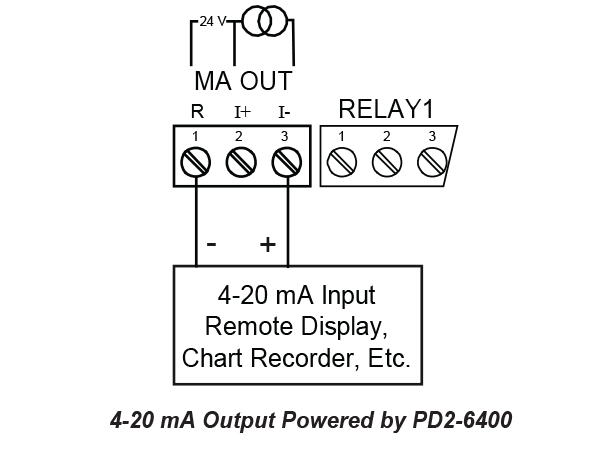

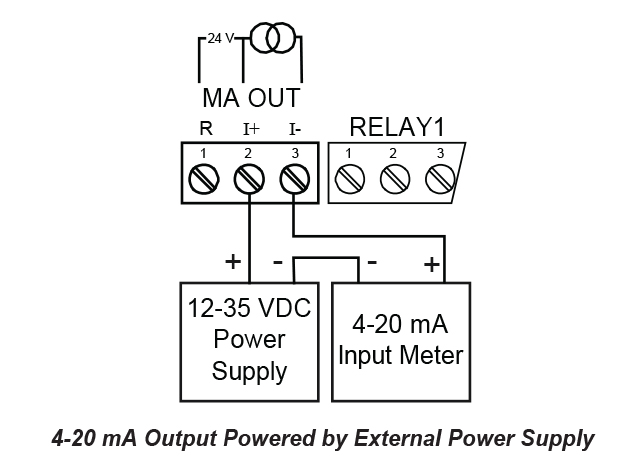

Connections

The Helios can provide 40 mA at 24 VDC to power the 4-20 mA output signal or an external power supply can be used:

The internal 24 VDC power supply powering the analog output may be used to power other devices, if the analog output is not used. The I+ terminal is the +24 V and the R terminal is the return.

The 4-20 mA output can either be programmed using the front panel push buttons or free MeterView Pro software.

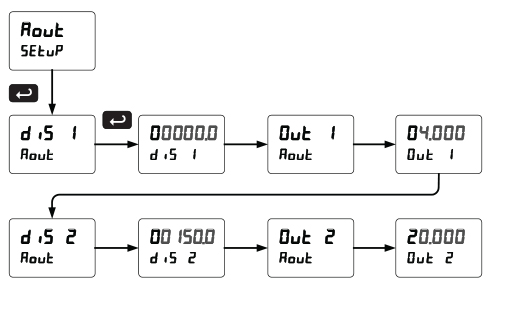

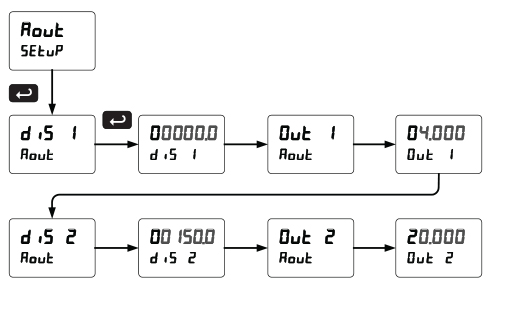

Front Panel Push Button Programming

The 4-20 mA analog output can be scaled to provide a 4-20 mA signal for any display range selected. No equipment is needed to scale the analog output; simply program the display values to the corresponding mA output signal. The Analog Output menu is used to program the 4-20 mA output based on display values.

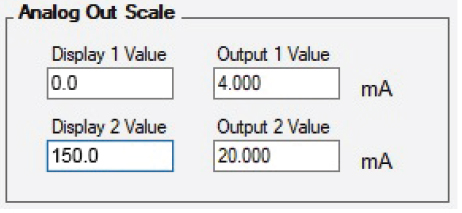

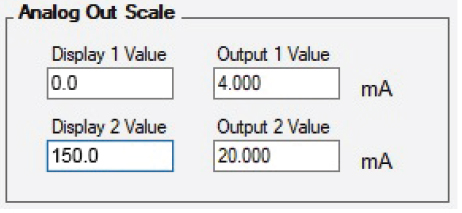

MeterView Pro Software Programming

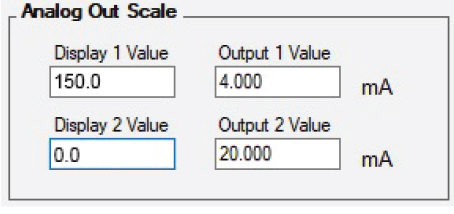

When a meter is programmed as shown below, the output will be 4.00 mA when the display reads 0 and the output will be 20.00 mA when the display reads 150.0.

The meter can be set up for reverse scaling as shown below: the output will be 4.00 mA when the display reads 150.0 and the output will be 20.00 mA when the display reads 0.

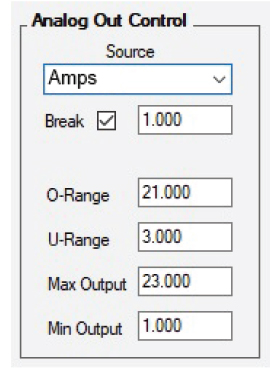

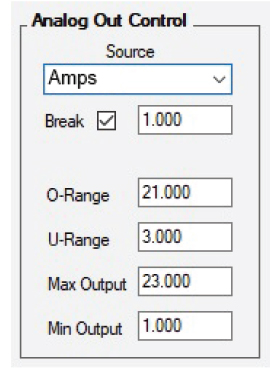

Source: Source for generating the 4-20 mA output (e.g. Amps)

Overrange: Analog output value with display in overrange condition

Underrange: Analog output value with display in underrange condition

Break: Analog output value when current input break is detected

Max: Maximum analog output value allowed regardless of input

Min: Minimum analog output value allowed regardless of input

Relays for Alarm & Control Applications

Adding relays to the Helios meter turns it into a sophisticated alarm device as well as a powerful, yet simple, alternative to a more complicated PLC system for control applications. The Helios can be equipped with four 3 A Form C (SPDT) internal relays. Relays are highly user-configurable as the following screen shot from MeterView Pro indicates:

*Values are intended to show programming choices. They are not intended to represent an actual application.

Setting Set and Reset Points (HI / LO Alarms)

All relays are independent of each other and may be programmed as high or low alarms with user desired set and reset points. Setting a set point above a reset point results in a high alarm and setting a set point below a reset point results in a low alarm. Alarms have 0 – 100% deadband and set and reset points may be set anywhere in the range of the meter.

Resetting the Relays (Action in MV Pro)

All relays are independent of each other and may be programmed to reset (Action in MV Pro) in the following ways:

- Automatic: Alarm will reset automatically once the alarm condition has cleared.

- Automatic/Manual: Alarm will reset automatically once the alarm condition has cleared but can also be reset at any time with a switch wired across terminals F4 and Common*.

- Latching: Alarm must be reset manually and can be done so at any time with a switch wired across terminals F4 and Common*.

- Latching with Reset after Cleared: Alarm must be reset manually and can only be done so after the alarm condition has cleared with a switch wired across terminals F4 and Common*.

* Or via one of the four digital inputs

Time Delay (On and Off)

In many applications it is desirable to wait before turning off or on a relay – such as waiting for a process to settle before taking action. Each relay on the Helios can be programmed with independent on and off time delays of 0 to 999.9 seconds to achieve this.

Relays Auto Initialization

When power is applied to the meter, the front panel LEDs and alarm relays will reflect the state of the input to the meter.

Signal Loss or Current Input Break Relay Operation

When the meter detects a break in the current input, the relay will go to one of the following selected actions:

- Turn On (Go to alarm condition)

- Turn Off (Go to non-alarm condition)

- Ignore (Processed as a low signal condition)

User Selectable Fail-Safe Operation

All relays are independent of each other and may be programmed for user selectable fail-safe operation. With the fail-safe feature activated, the relays will transfer to the alarm state on power loss to the meter.

Front Panel LEDs

The meter is supplied with four alarm points that include front panel LEDs to indicate alarm conditions. This standard feature is particularly useful for alarm applications that require visual-only indication.

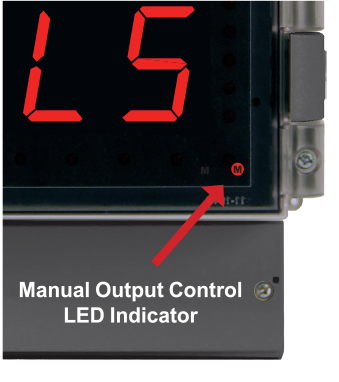

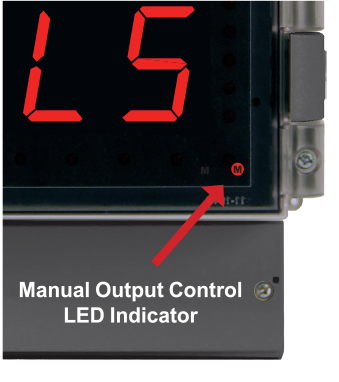

Manual Output Control

Take control of any output with this feature. All relays can be forced ON or OFF, and the 4-20 mA output signal can be set to any value within its range. When the relays and 4-20 mA output are controlled manually, an LED labeled “M” is turned on and the associated Alarm LEDs (1-8) flash every 10 seconds indicating that the meter is in manual control mode.

Sampling Function (PV Triggered Timed Relay)

The sampling function allows the operator to set a relay as a “sampling” relay. When the PV reaches that set point, it will close that relay’s contacts for a preset period of time (0.1 to 5999.9 seconds).

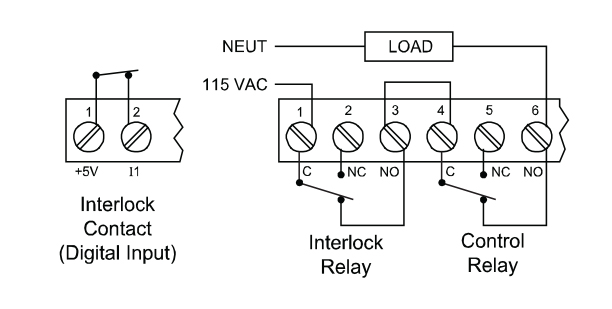

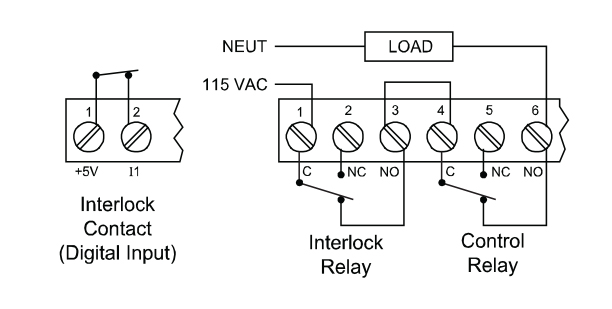

Interlock Relay(s)

This function allows a process to use one or more very low voltage input signals or simple switch contacts to control the state of one or more internal “interlock” relays. A violation (i.e. loss of input, open switch, or open circuit) forces one or more N/O interlock relay contacts to open. One input can be used in series with a number of interlock switches, or up to four inputs can be required to force-on one (or more) internal interlock relays. Please see Safety Interlock on the ProVu Series whitepaper on our website for more information.

Switching Inductive Loads

The use of suppressors (snubbers) is strongly recommended when switching inductive loads to prevent disrupting the microprocessor’s operation. The suppressors also prolong the life of the relay contacts. Precision Digital offers the PDX6901 Snubber with 0.01μF/470Ω flexible leads.

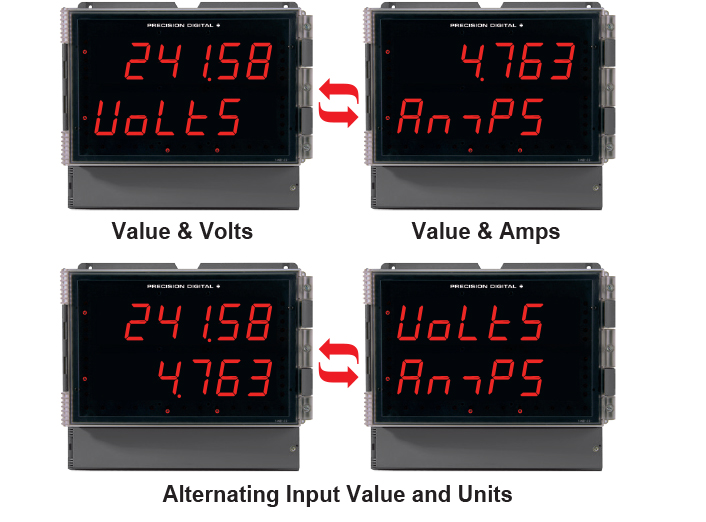

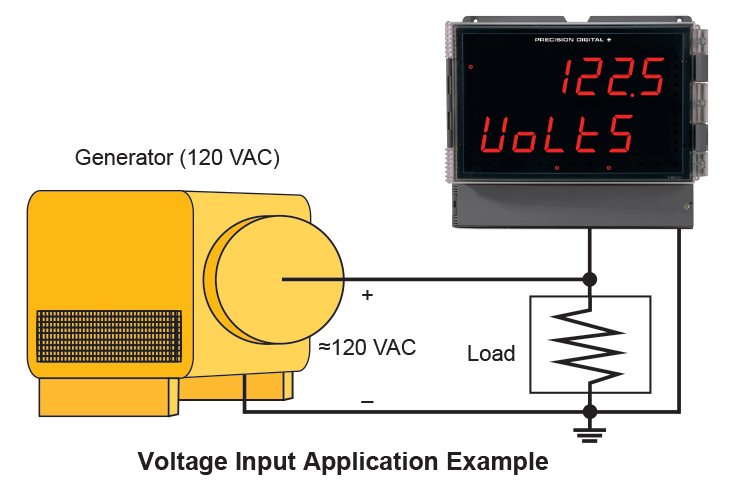

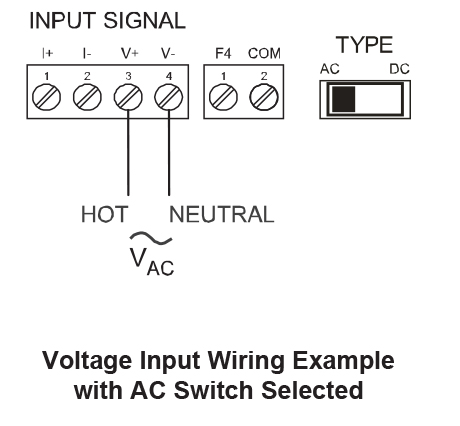

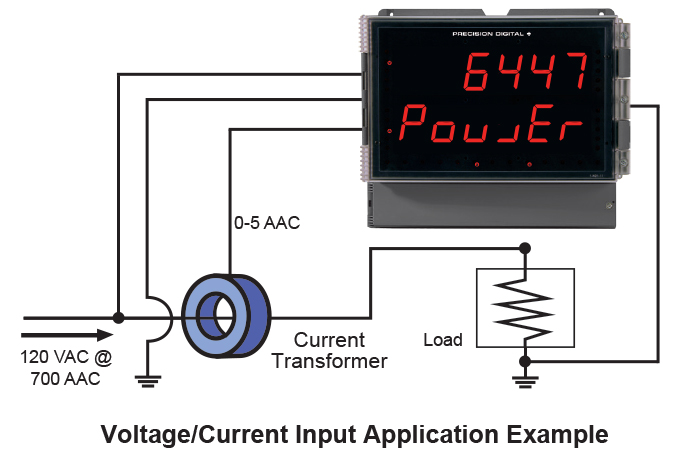

Application Examples

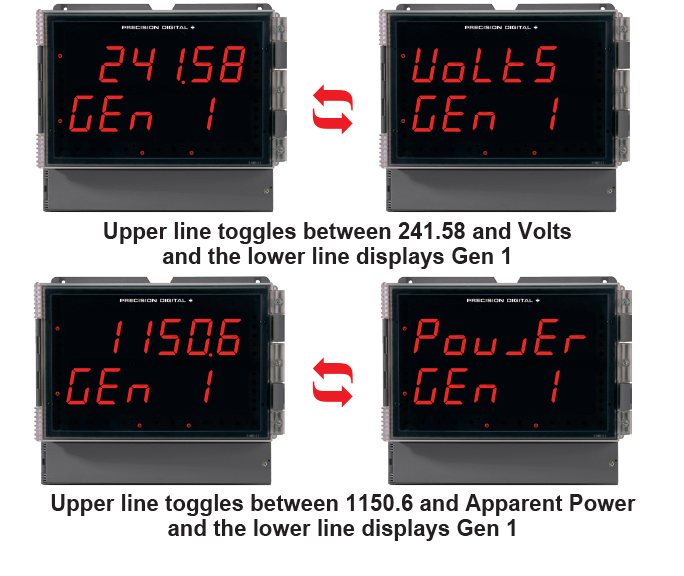

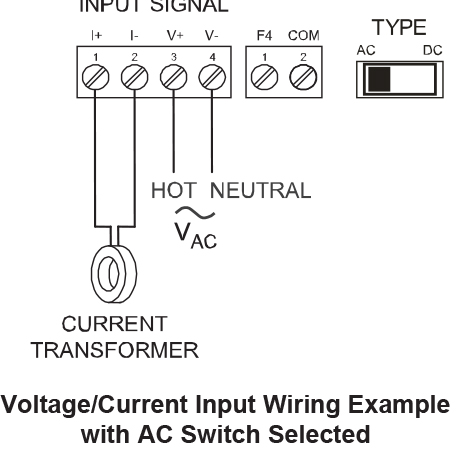

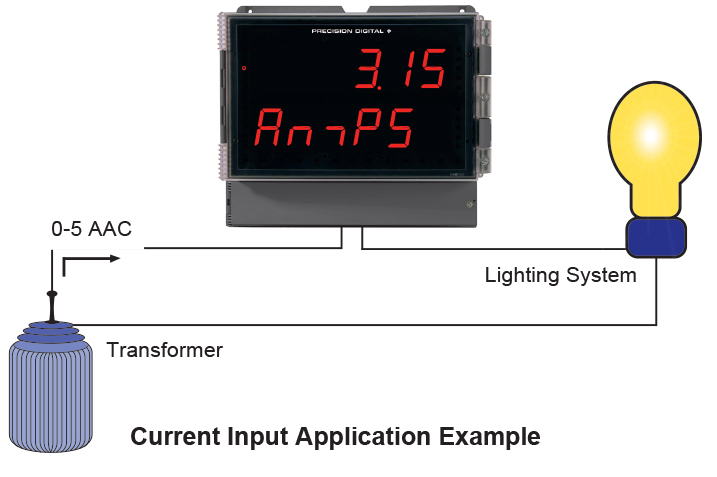

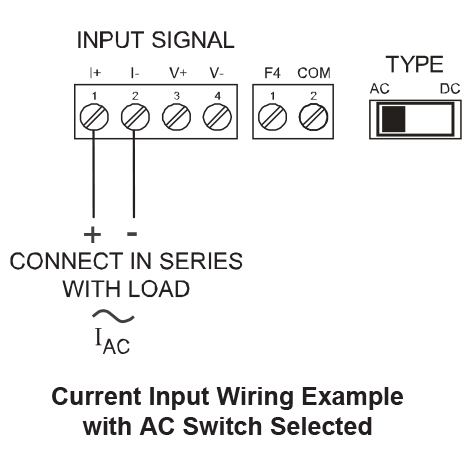

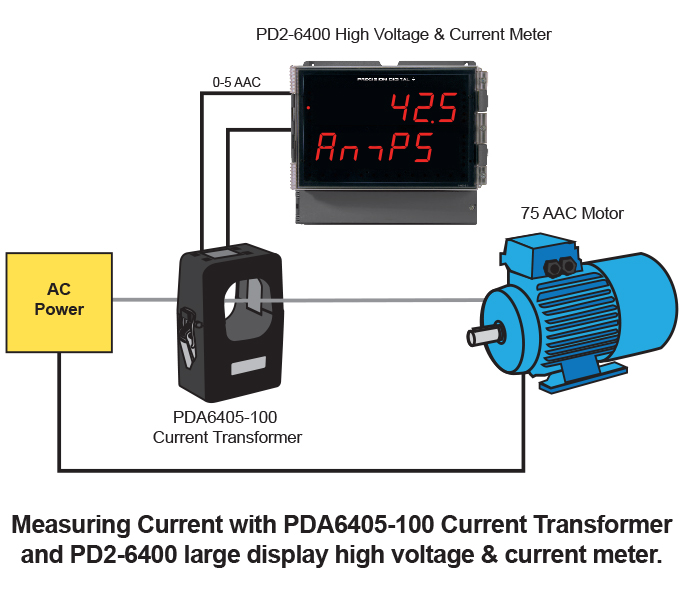

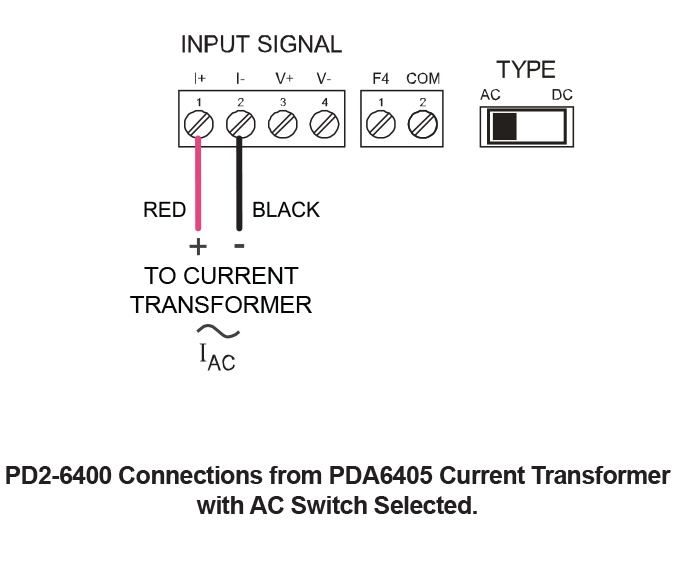

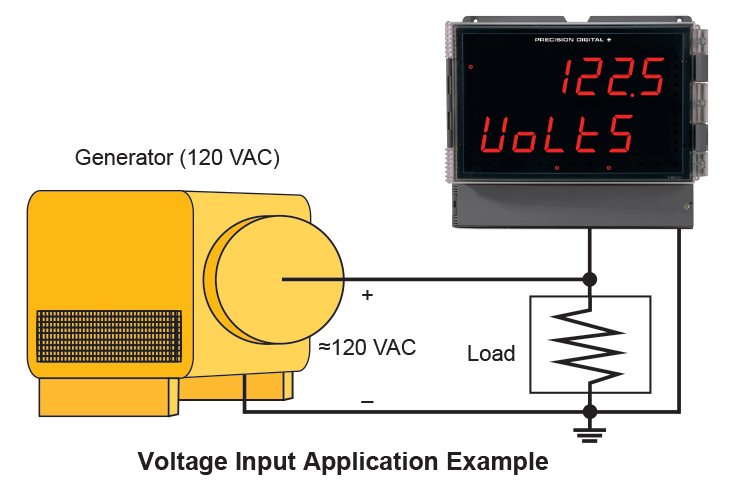

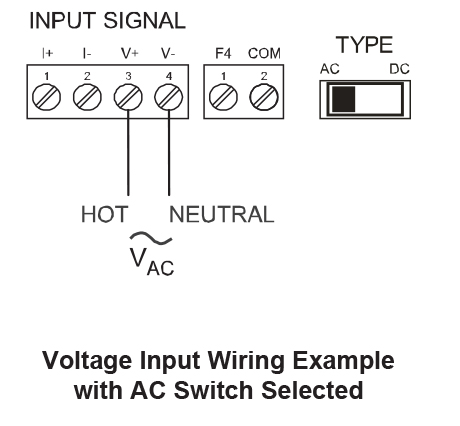

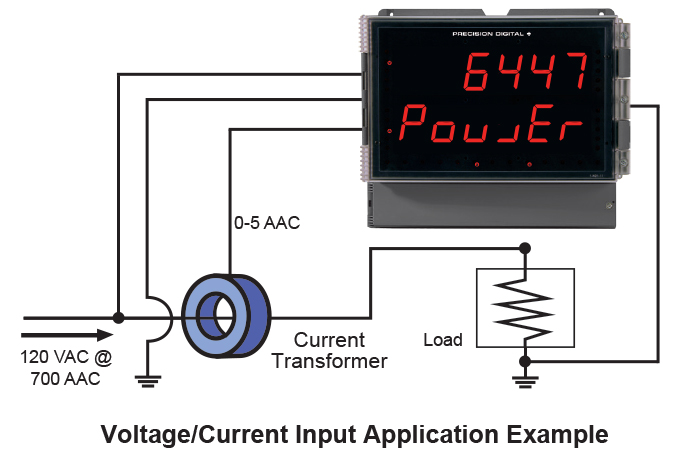

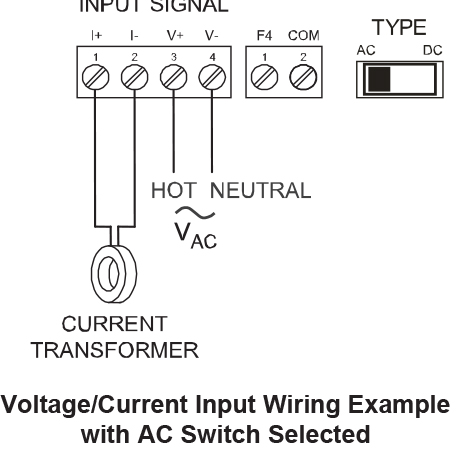

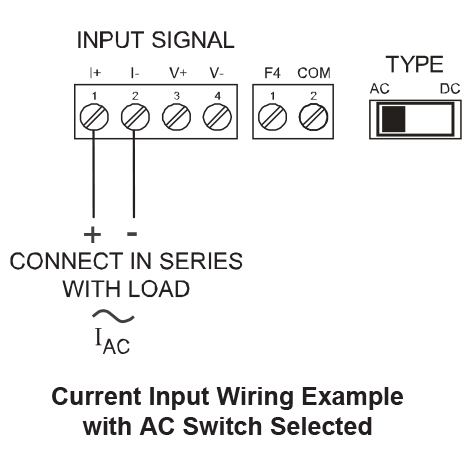

The PD2-6400 Helios can be used to display application data for voltage, current, or both. Each Channel, Voltage or Current, can be scaled independently. The following examples show just a few of the PD2-6400's application capabilities using generators and transformers. Each example is followed by a wiring diagram that shows proper switch position for the meter.

Voltage Measurement for a Generator Driving a Load

Apparent Power Measurement Using a Current Transformer

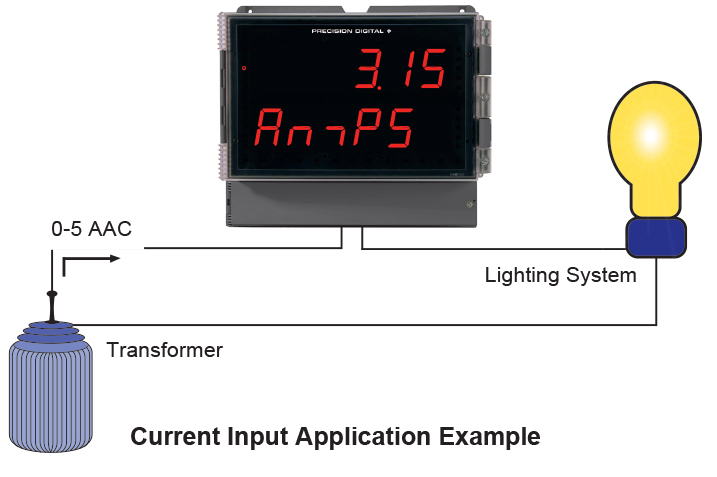

Current Measurement for a Lighting System

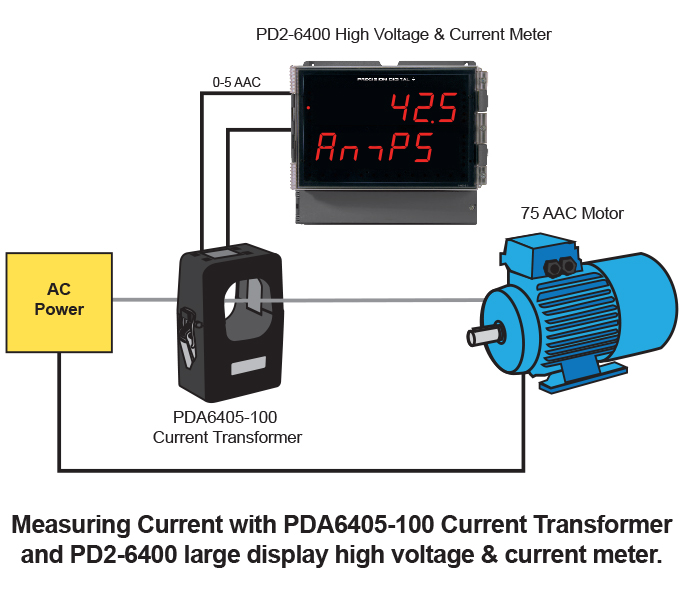

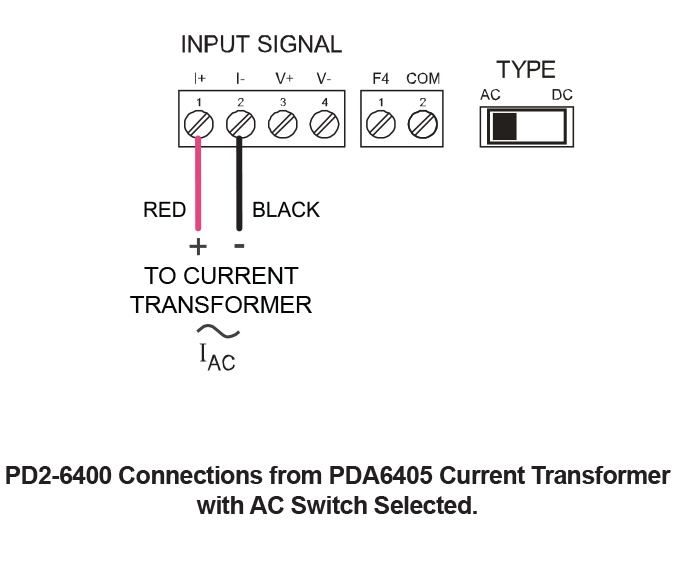

Converting High AC Current with the PDA6405 Split Core AC Current Transformer

PDA6405 Split Core AC Current Transformers

Precision Digital offers a line of split core AC current transformers that convert the high AC current flowing through a cable or wire to a 0-5 AAC output that can be displayed on a PD6400. The PDA6420 works with a PD6400 because it puts out a 4-20 mA signal. They are available in ranges of 100, 200, 400, 600, and 1000 AAC. These nonintrusive devices feature split core convenience for easy installation and are a cost effective solution for monitoring load or proof of operation. The PDA6420 current transformers are ideal for monitoring current loads on pumps, driving fans and blowers, and sensing the status of heating coils and lighting.

Specifications

Current Range: 100A, 200A, 400A, 600A, and 1000A (based on model)

Output: 0-5 A

Accuracy: +/- 1%

Burden: 2VA

Insulation Voltage: CAT IV 250 or CAT III 600VAC

Maximum Primary Voltage: 5000 VAC (Insulated Conductor)

Phase Angle: Less than 2 degrees at 50% of rated current

Frequency Range: 50/60 Hz

Operating Temperature: -40 to 55°C

Humidity: 0-95% RH non-condensing, Indoor use only

Pollution Degree: 2

Leads: 18AWG 1.0 m cable

UL File Number: UL recognized for US and Canada (E341727)

Digital Communications

Modbus® RTU Serial Communications

With onboard RS-485 serial communication, the PD2-6400 can communicate with any Modbus master device using the popular Modbus communications protocol that is included in every Helios. In addition to the typical Modbus capabilities of reading PVs and writing set points, below are some examples of other things that can be done with the meter’s Modbus communications:

- Send a 6-character message to the lower display upon an event

- Convert a digital value to a 4-20 mA signal

- Remoteusercontrol(i.e.changesetpoints,acknowledge alarms)

- Input a Modbus digital PV (in place of analog input)

- Remote override of any, or all, relays and analog outputs

Additional Communication Modules

In addition to RS-485 communications which is a standard feature, the Helios is available with serial communications modules for RS-232 and USB.

PDA7485-I

RS-232 to RS-422/485 Isolated Converter |  PDA8485-I

USB to RS-422/485 Isolated Converter |  |

*All adapters and connectors supplied with appropriate cables.

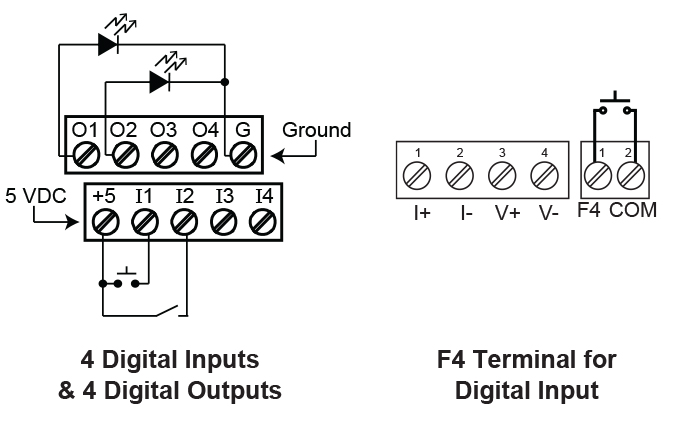

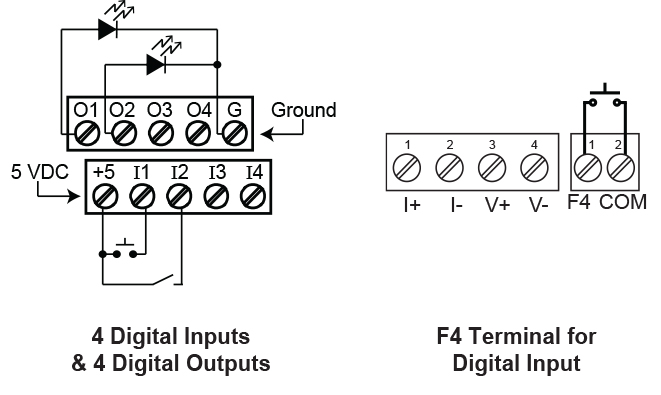

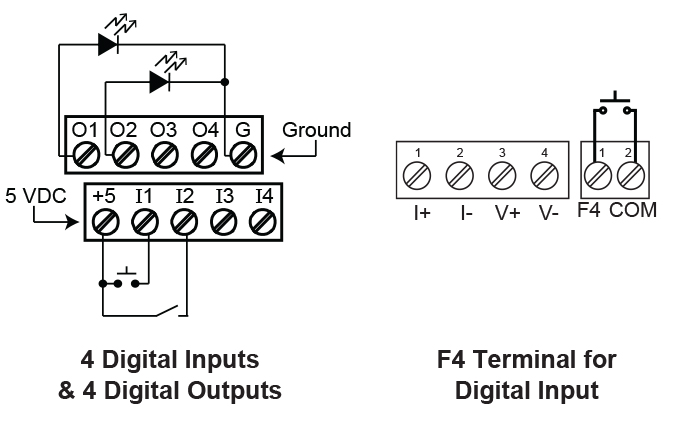

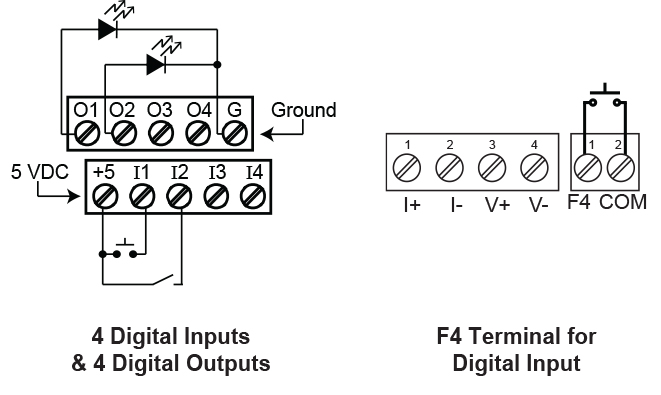

On-Board Digital Inputs and Outputs

The PD2-6400 includes five (5) digital inputs and four (4) digital outputs standard. Since the Helios is a large display meter it is often mounted in areas where it is not convenient to access the programming buttons. The digital inputs can be set up to mimic the four programming buttons on the Helios meter, thus making it possible to mount remote buttons for programming in a more convenient location. In addition, the digital inputs can also be used to reset the total, operate the tare feature, reset the tare, and more. The digital outputs can be used to drive alarming devices or as a means to communicate alarm conditions with a PLC.

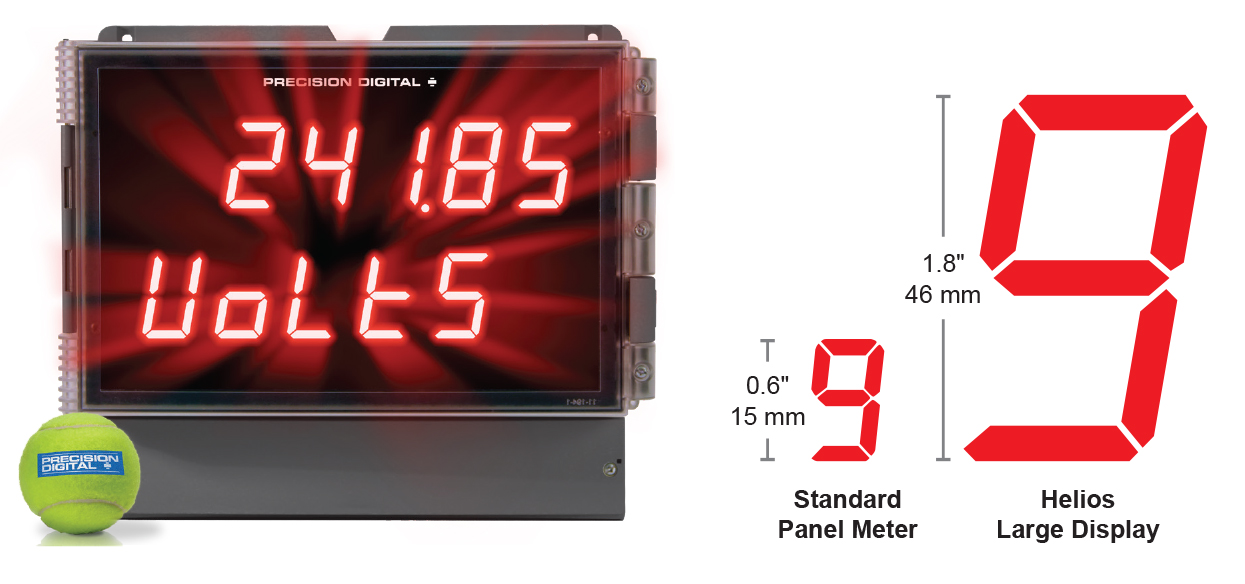

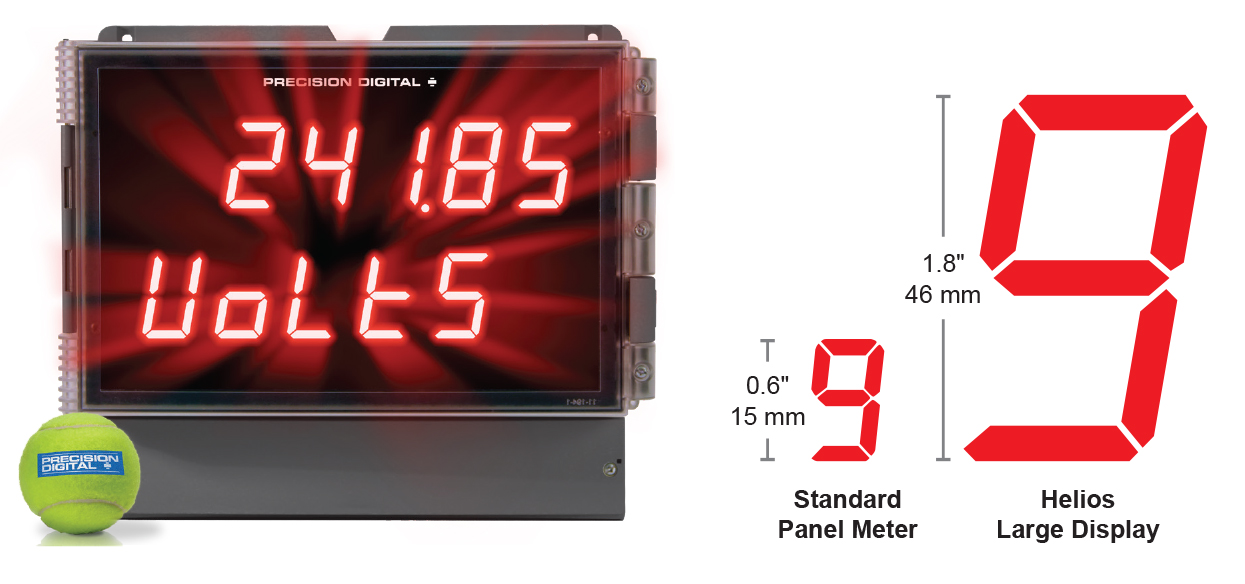

Physical Features

The most striking physical feature of the Helios meter is its dual-line 6-digit display with 1.8" high super-bright LEDs. These allow the display to be read from up to 100 feet away, even in bright sunlight.

The Helios is designed for ease-of-use in industrial applications where it will be exposed to wet, dusty, hot, cold and other adverse conditions. The Helios is housed in a rugged NEMA 4X enclosure, can operate over a wide temperature range, includes removable screw terminal connectors, and is UL Listed for electrical safety. All of these features are backed by a 3-year warranty.

Super-Bright 1.8" High LED Display

The Helios features super-bright 1.8" high LEDs; three times the height of standard digital panel meters.

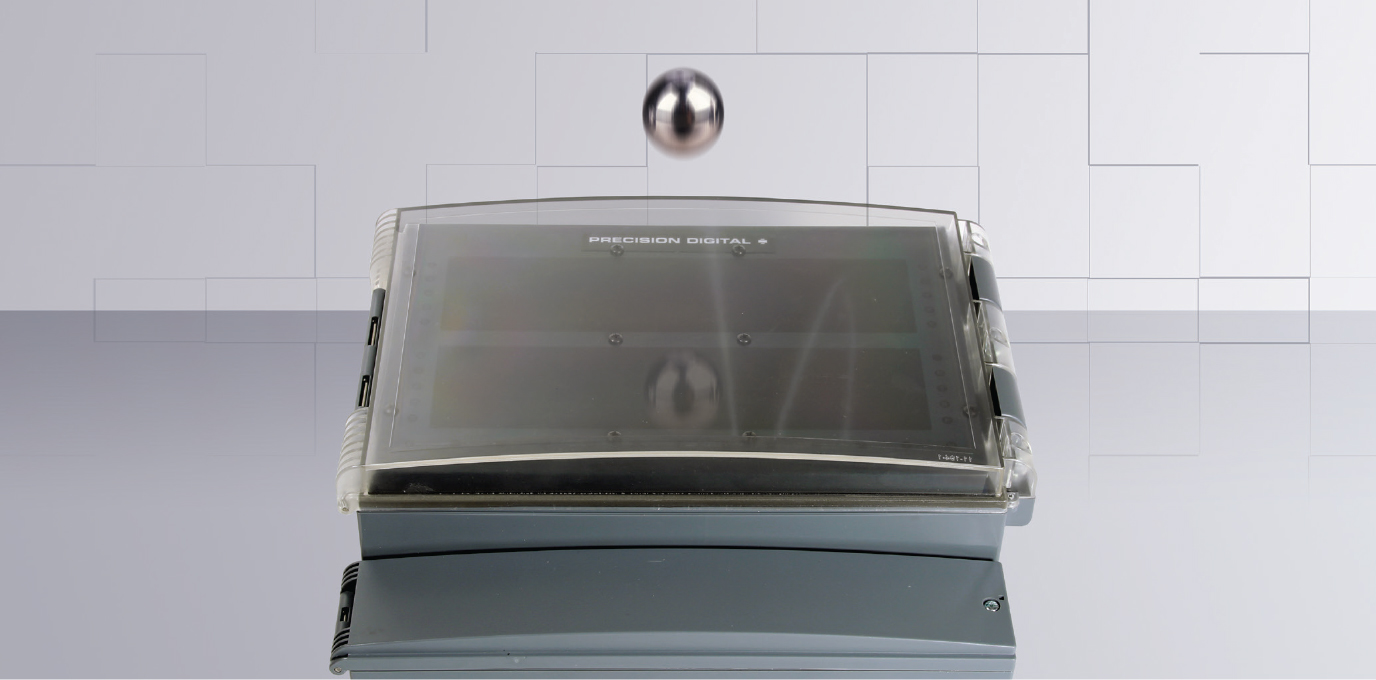

Type 4X / NEMA 4X Front Panel

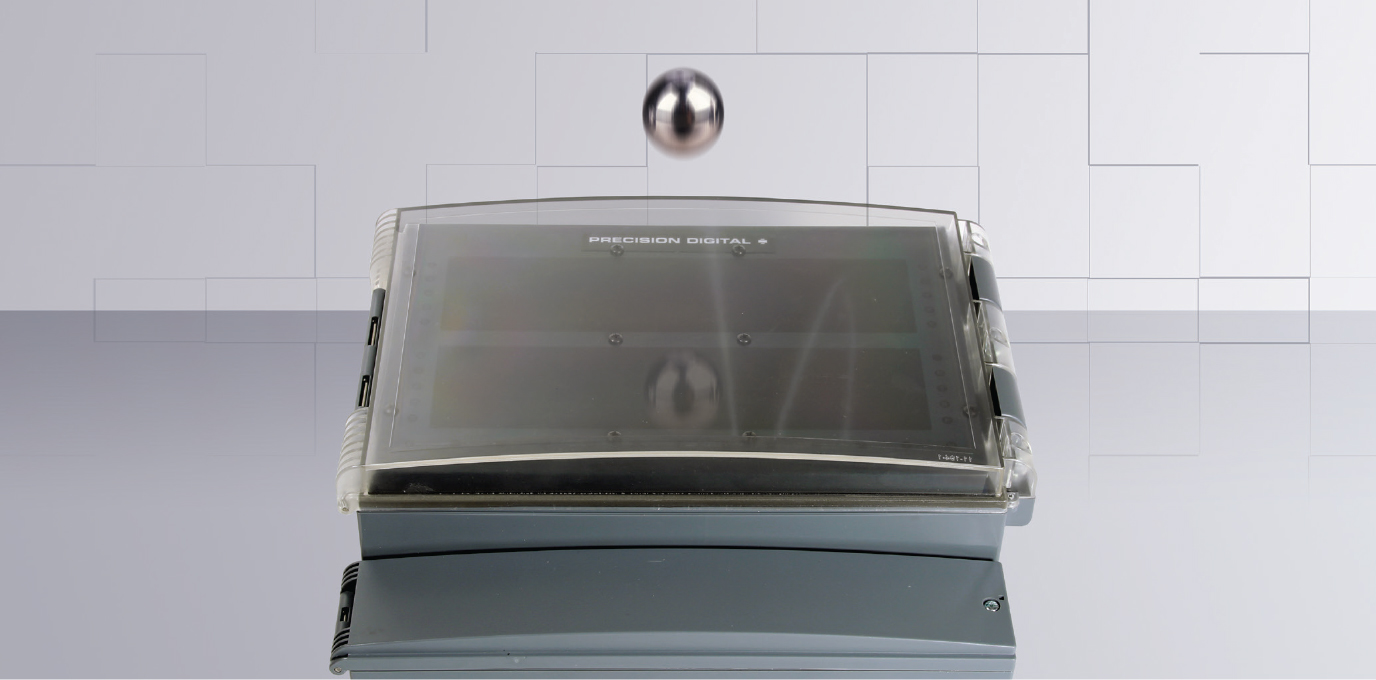

| Not only does the Helios’s front panel UL Type 4X approval indicate it is waterproof, but it also indicates it is rugged. Part of the UL Type 4X test is to drop a 2 inch solid stainless steel ball from 8 feet on top of the meter’s cover. |

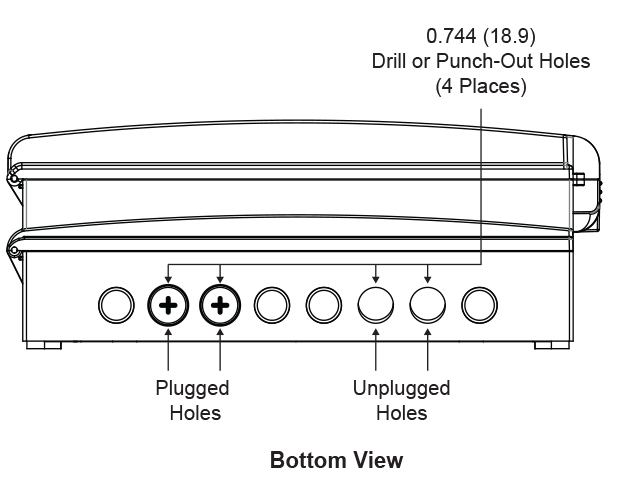

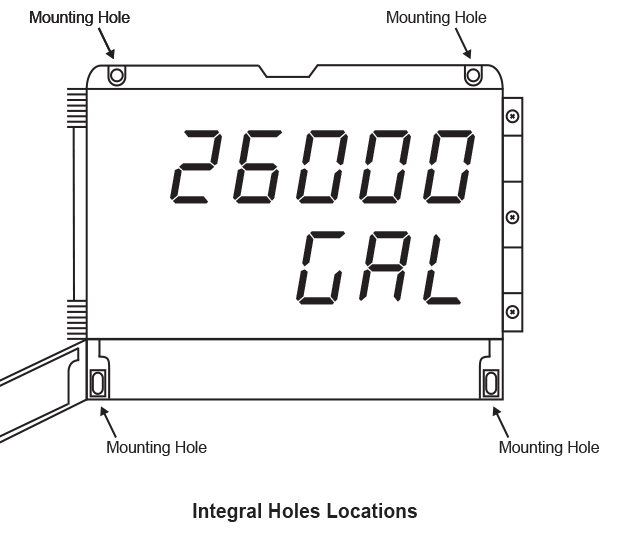

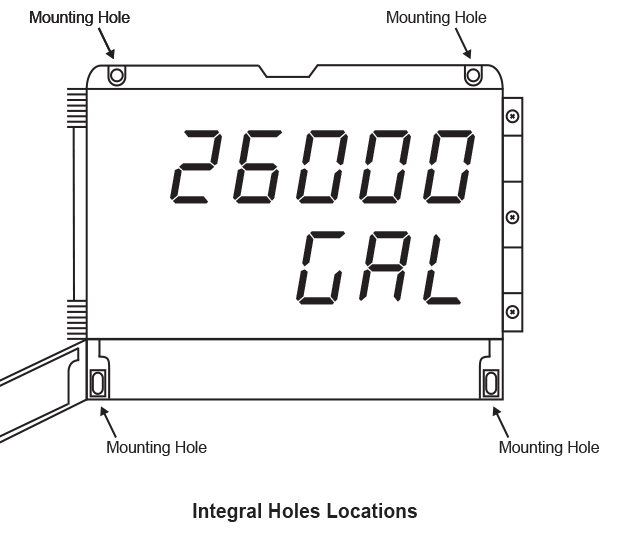

Integral Holes for Wall Mounting

The Helios’s back panel includes four holes for convenient wall mounting.

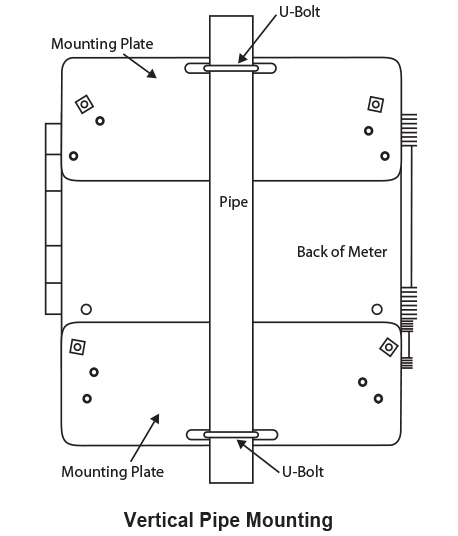

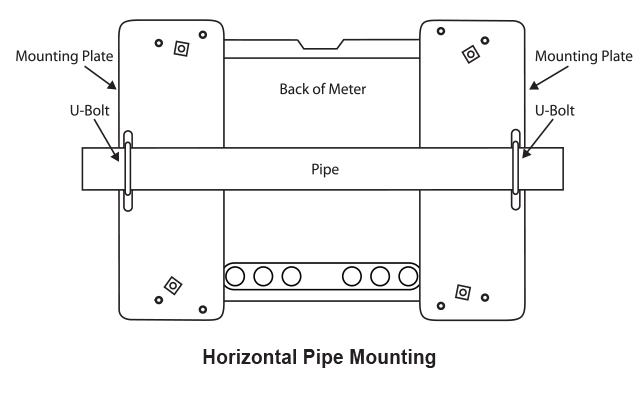

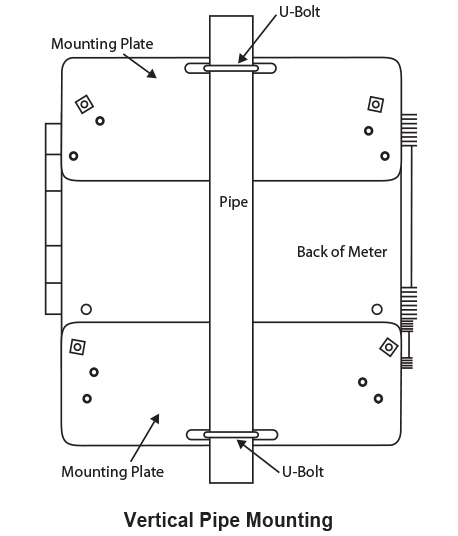

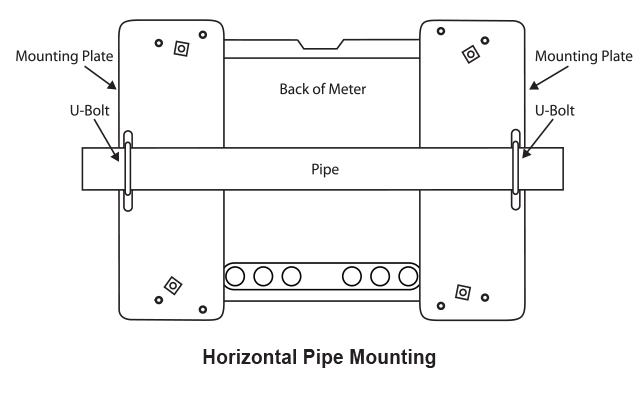

Pipe Mounting Kit

The meter can also be mounted to a pipe using the optional pipe mounting kit (PDA6260). This kit includes two mounting plates, two U-bolts, and the necessary nuts and bolts. See PD2-6400 manual for instructions.

USB Port for Easy Connection to MeterView Pro Free Software

Wide Operating Temperature Range

The Helios can operate from -40 to 65°C (-40 to 150°F) meaning it can be installed in a wide variety of indoor and outdoor industrial applications. And over this range the Helios will drift no more than 0.005% of calibrated span/°C max from 0 to 65°C ambient and 0.01% of calibrated span/°C max from -40 to 0°C ambient.

Removable Screw Terminal Connectors

Industrial applications require screw terminal connections for easy field wiring and the Helios goes one step further in convenience by making them removable also.

UL Listing for Electrical Safety

UL & C-UL Listed: USA & Canada

UL 508 Industrial Control Equipment

UL File Number: E160849

Front Panel: UL Type 4X, NEMA 4X, IP65

Low Voltage Directive:

EN 61010-1:2010. Safety requirements for measurement, control, and laboratory use.

Operational Features

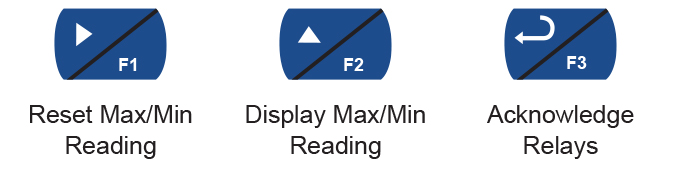

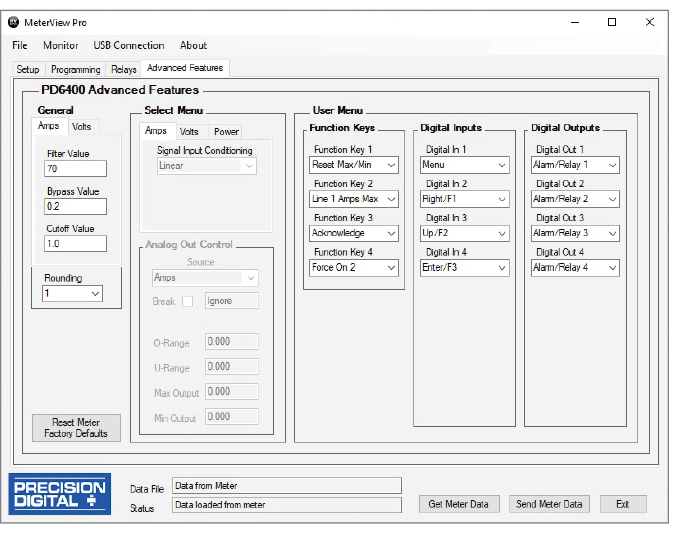

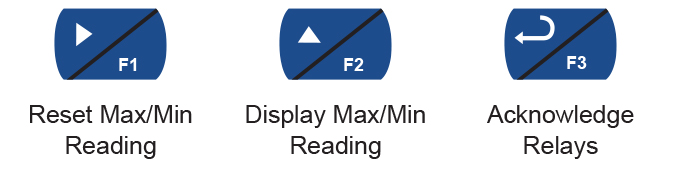

Function Keys, F4 Terminal, Digital Inputs

There are two ways the user can interact with the Helios to perform a variety of useful functions:

1. Three Buttons Under the Front Cover

The default settings for the function keys are:

2. Built-in Digital Inputs/Outputs

The Helios comes with five digital inputs and four digital outputs. The digital inputs can operate with the interlock relays feature, force relays on from a signal from a PLC or relay on other equipment, and much more. The digital inputs can also be used to mimic the programming buttons, which are located behind a door and generally not accessible during operation. The digital outputs can be used to send signals to PLCs and other devices.

Remote Operation of Front Panel Buttons

The Helios’s programming buttons are located behind a door and generally not accessible during operation. Digital inputs are provided that can be wired to remote buttons to operate the programming buttons in a convenient location. MeterView Pro provides an easy way to do this programming:

Max / Min Display

Max/Min (or Peak/Valley) is standard on the Helios PD2-6400. Either display can be configured to show either maximum or minimum excursion since last reset. The displays can also be configured to toggle between Max and Min values. Both values can be simply reset from the front panel.

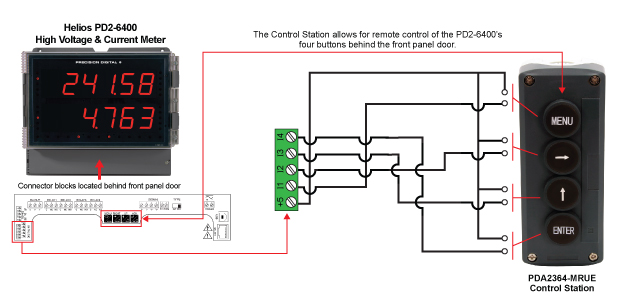

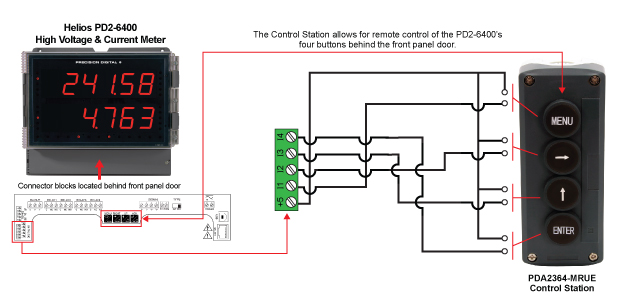

Remote Operation Using PDA2364-MRUE Control Station

The PD2-6400's four internal programming and operations buttons can be remotely controlled by using the PDA2364-MRUE 4-button control station accessory as shown in the diagram below.

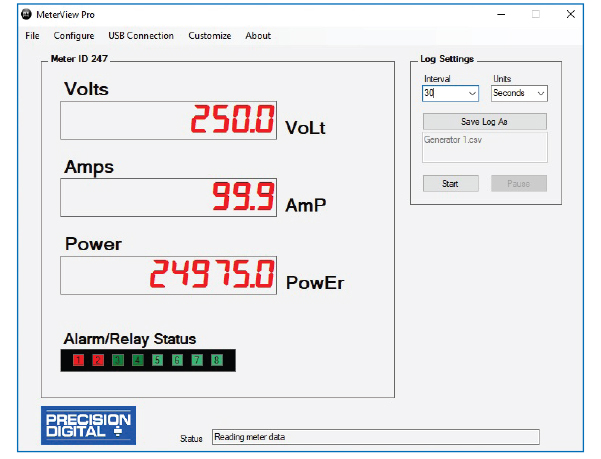

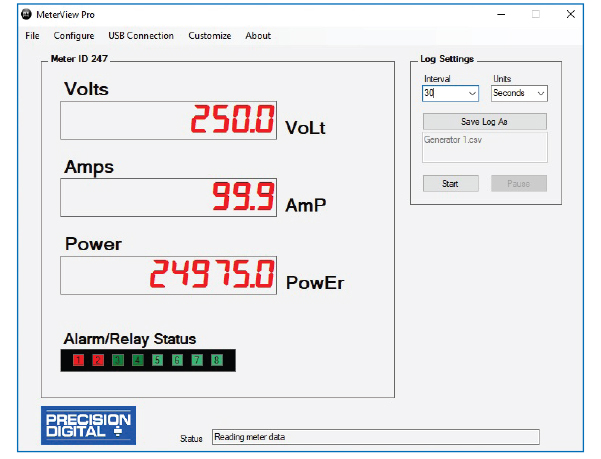

MeterView Pro Monitoring & Datalogging Software

Not only does free MeterView Pro software greatly simplify setup and programming of the Helios, it can also be used to monitor and datalog your process.

- Custom Tags: i.e. Power

- Custom Units: i.e. Amps, Volts

- Alarm Status Indicators

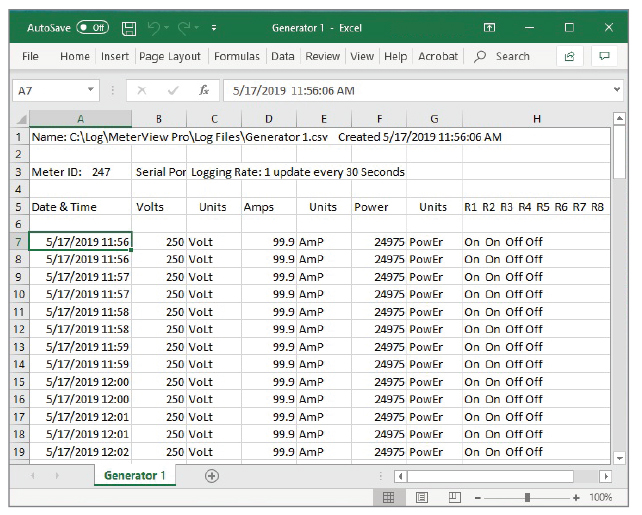

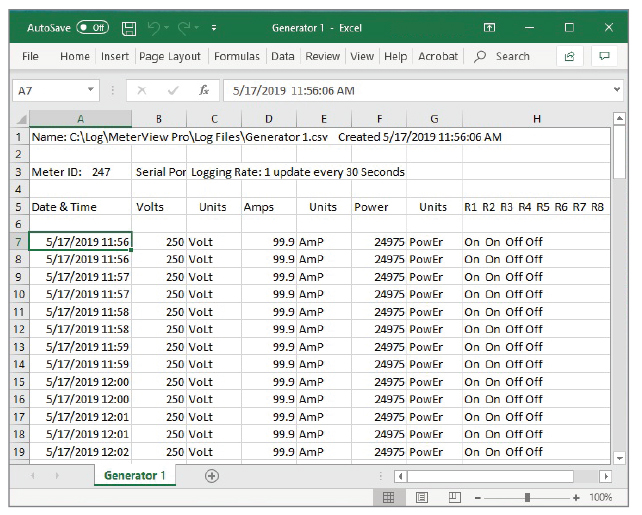

Datalog Report

Collected data logger information can be sent to a CSV file for importing into a spreadsheet program. Below is an example of one such file. Of course, once within the spreadsheet, much can be done to customize the data.

Relay Control

Relays can be controlled from MeterView Pro for testing purposes. This is commonly done to determine whether the relays are functioning properly. In the Setup window, under Relay and Digital Out Test you have the option of selecting the relays you want in an ON state or OFF state and also whether you want to leave the relays in manual control or to return them to automatic operation.

Plastic Control Stations For The Helios PD6400

The PDA2360 series of plastic control stations provide a convenient way to remotely control devices such as Precision Digital’s Helios PD2-6400. The PDA2364-MRUE four-position control station mimics the Helios’s four buttons behind the front panel door: Menu, Right Arrow, Up Arrow, and Enter. The PDA2360-E is an emergency stop button and the PDA2361-A is used to acknowledge an alarm.

- Complete Pre-Assembled Stations

- Normally Open (NO) Spring Return Plastic Bezel Pushbuttons

- Trigger Action Turn to Release Pushbutton (PDA2360-E only)

- IP65 / NEMA 4, 4X and 13 Rated

- Four-Position Control Station for Remote Operation of Helios Buttons

- Wall Mountable

| PDA2360 Series Control Stations |

| Model | Description |

| PDA2360-E | Emergency Stop Button |

| PDA2361-A | 1 Black Ack Button |

| PDA2364-MRUE | 4 Black Buttons: Menu, Right, Up, Enter |

Function Key, Digital Inputs, & Digital Outputs Descriptions

The following table describes the actions that Helios function keys and digital inputs can be programmed to perform. The table also describes how the digital outputs can be used to remotely monitor the Helios’s alarm relay states, or the states of a variety of actions and functions executed by the meter.

| Display | Description | Item |

| Reset the stored maximum display value | FK, DI, DO |

| Reset the stored minimum display value | FK, DI, DO |

| Reset the stored maximum & minimum display values | FK, DI, DO |

| Capture tare and zero the display | FK, DI, DO |

| Reset captured tare and resume normal operation | FK, DI, DO |

| Directly access the relay menu | FK, DI |

| Directly access the set point menu for relay 1 (*through 8) | FK, DI |

| Disable all relays until a button assigned to enable relays (Rly E) is pressed | FK, DI |

| Enable all relays to function as they have been programmed | FK, DI |

| Hold current relay states and analog output as they are until a button assigned to enable relays (Rly E) is pressed | FK, DI |

| Hold the current display value, relay states, and analog output momentarily while the function key or digital input is active. The process value will continue to be calculated in the background. | FK, DI |

| Display maximum display value on line 1 | FK, DI |

| Display minimum display value on line 1 | FK, DI |

| Display maximum & minimum display values on line 1 | FK, DI |

| Display maximum display value on line 2 | FK, DI |

| Display minimum display value on line 2 | FK, DI |

| Display maximum & minimum display values on line 2 | FK, DI |

| Force relay 1 (*through 4) into the on state. This is used in conjunction with a digital input expansion module to achieve interlock functionality. | FK, DI |

| Directly access the control menu | FK, DI |

| Disable the selected function key or digital I/O | FK, DI |

| Acknowledge all active relays that are in a manual operation mode such as auto-manual or latching | FK, DI, DO |

| Directly access the reset menu | FK, DI |

| Mimic the menu button functionality (digital inputs only) | DI |

| Mimic the right arrow/F1 button functionality (digital inputs only) | DI |

| Mimic the up arrow/F2 button functionality (digital inputs only) | DI |

| Mimic the enter/F3 button functionality (digital inputs only) | DI |

| Provide indication when alarm 1 (*through 8) has been triggered (digital outputs only) | DO |

FK: Function Keys DI: Digital Inputs DO: Digital Outputs

Connections

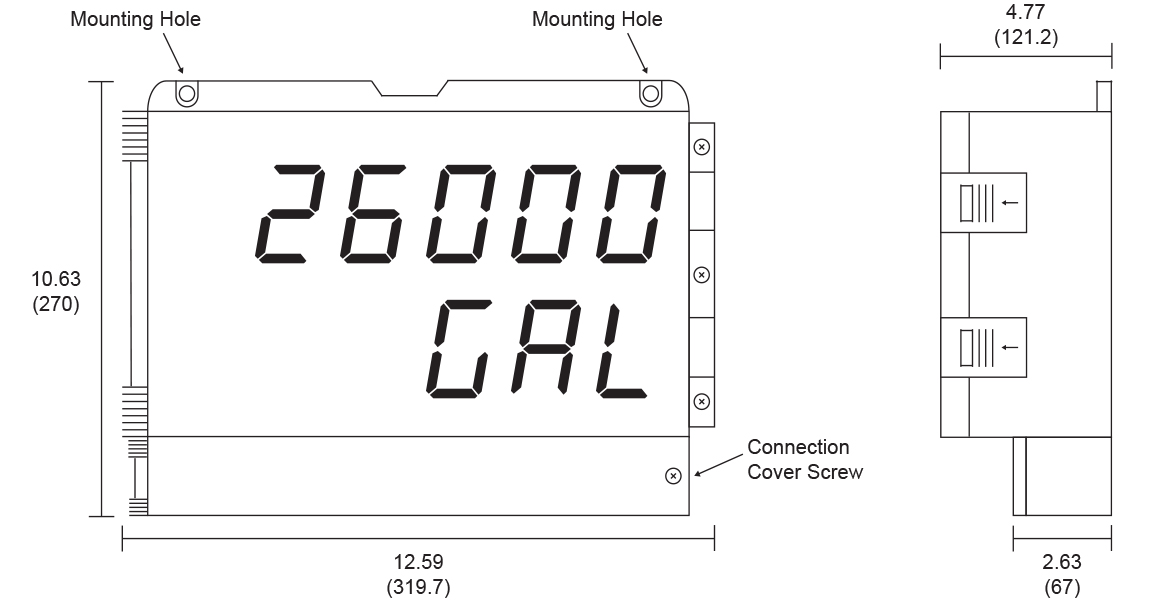

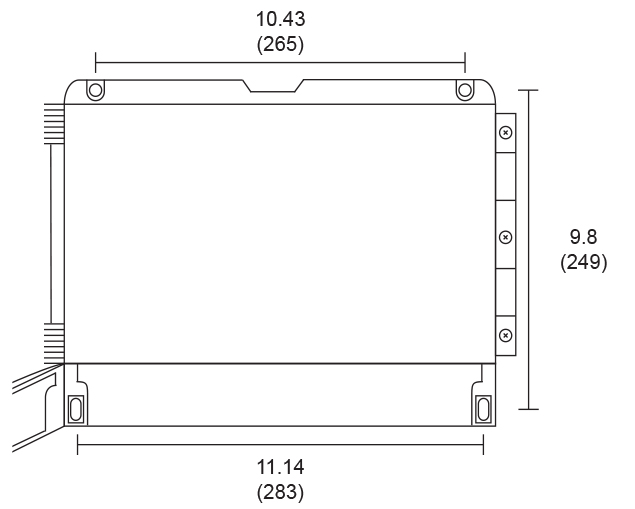

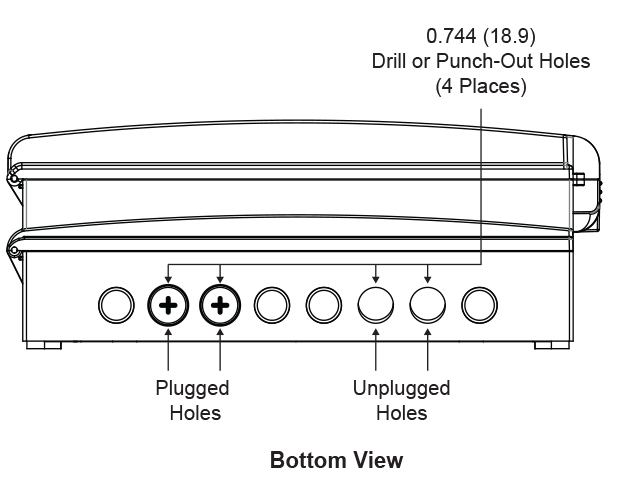

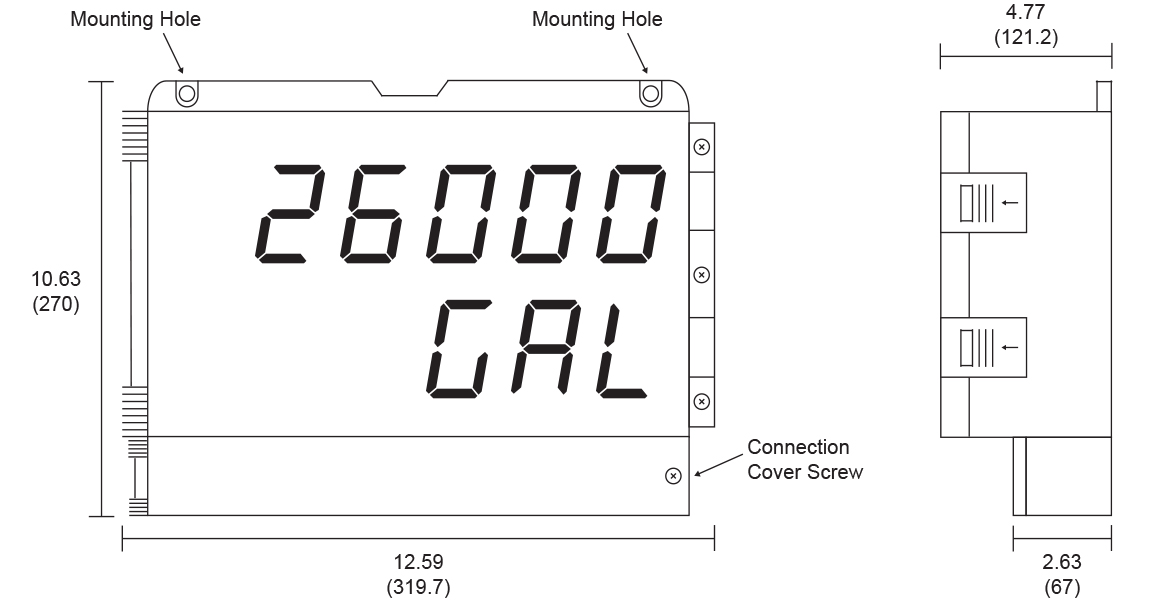

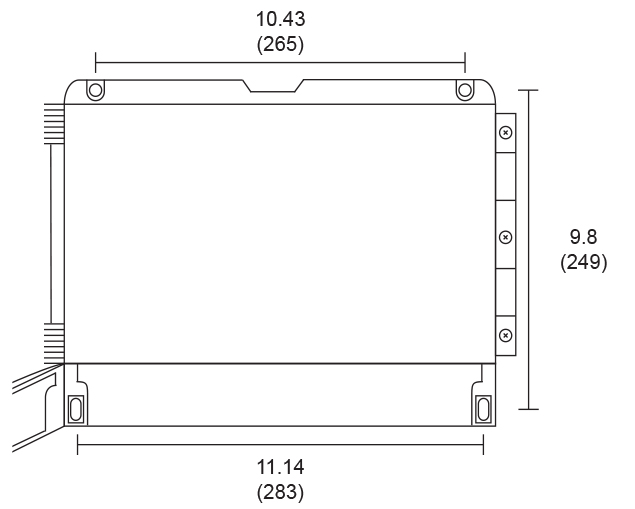

Dimensions Units: Inches (mm)

Front and Side View

Wall Mounting Holes Location

Conduit Holes Location