Features

- 100A, 200A, 400A, 600A, and 1000A Ranges

- 0-5A Output

- Split Core Convenience

- Compact Design

- 1% Accuracy

- UL recognized for US and Canada (E341727)

Overview

The PDA6405 Current Transformers convert the high current flowing through a cable or wire to a 0-5 A output and are available in ranges of 100, 200, 400, 600, and 1000 Amps. These nonintrusive devices feature split core convenience for easy installation and are a cost-effective solution for monitoring load or proof of operation. These current transformers are ideal for monitoring current loads on pumps, driving fans and blowers, and sensing the status of heating coils and lighting.

IMPORTANT: The PDA6405 current transformer is intended to provide an input to equipment under normal operating conditions. Where failure or malfunction of the current transformer could lead to personal injury or property damage to the controlled equipment or other property, additional precautions must be designed into the control system. Incorporate and maintain other devices, such as supervisory or alarm systems or safety or limit controls, intended to warn or protect against failure or malfunction of the current transducer device.

Installation

WARNING: Risk of Electrical Shock. Disconnect the power supply before making electrical connections. Contact with components carrying hazardous voltage can cause electric shock and may result in severe personal injury or death.

Wiring

- Disconnect the conductor cable from the power source.

- Snap the split core around the power conductor cable and close the core until the core snaps shut.

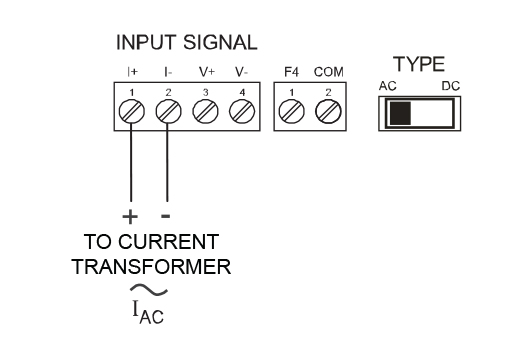

- Wire the output leads to desired device per Figure 2

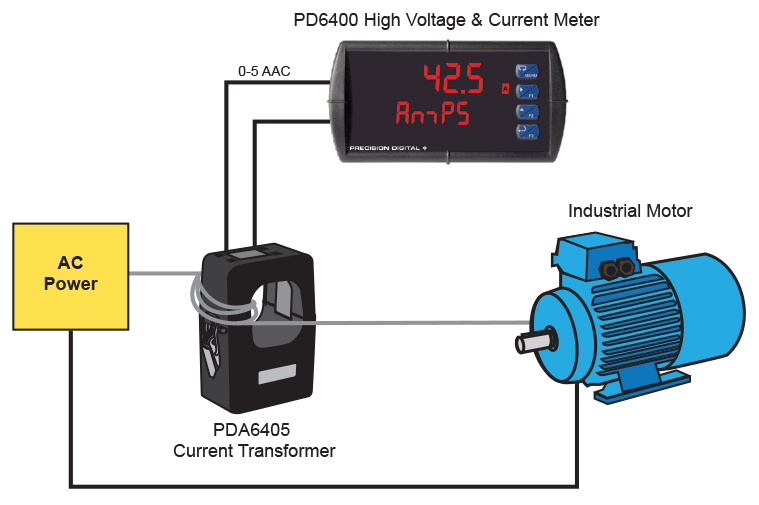

- Reconnect the power conductor cable. See Figure 3 for a wiring example.

If the measured current is too low to be detected or it is higher than the maximum current rating of the transformer, use the following methods to increase or decrease the current:

If Measured Current is Too Low to Be Detected

Wrap the conductor (wire) through the sensing hole and around the current transformer body to produce multiple turns to increase the measured current. The measured current is equal to the actual current multiplied by the number of turns. See Figure 1.

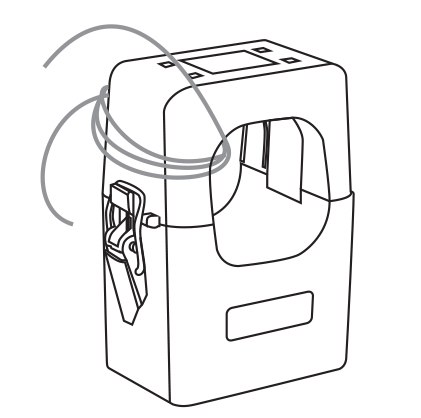

Figure 1: PDA6405 Current Transformer Shown with Four Turns

The controller must be scaled to account for the extra turns. If four turns pass through the transducer as shown in gure 1, the normal controller reading must be divided by 4.IMPORTANT: Failure to derate the current capacity could result in damage to the current transformer when using multiple turns to increase the measured current. Use the following formula to determine the new maximum current:

Example: If the maximum current rating of the CT is 100 A and the number of turns used is 4, then:

Maximum Line Current: 100 A / 4 = 25 A

The new maximum current is equal to the current transformer current rating divided by the number of turns.

Connections

Figure 2: Current Input Applications Example

Figure 3: Current Input Wiring Example with AC Switch Selected

ProVu PD6400 High Voltage & Current Digital Panel Meter

The PD6400 is a member of the ProVu series of 1/8 DIN digital panel meters that accepts a high voltage (0-300 VAC/ VDC) and high current (0-5 AAC/ADC) input simultaneously. It is ideal for measuring direct voltage and current or the output from voltage shunts and current transformers.