Overview

The PD685 is an easy to use, loop-powered indicator, certified by CSA, ATEX and IECEx as intrinsically safe. The PD685 carries international certifications under both the Class/Division System and Zone System, and is thereby suitable for use in gas and dust hazardous areas worldwide. For Division 2 applications where intrinsically safe interfaces are not needed, the PD685 is able to be installed without barriers! To achieve this ability, the PD685 underwent a special 'nonarcing assessment' under the UL 121201 and CSA C22.2 No. 213 standards, and was determined to be a device incapable of causing an ignition on its own. The PD685 is wellsuited for both indoor and outdoor applications and carries a variety of environmental ratings, including Type 4X and IP67.

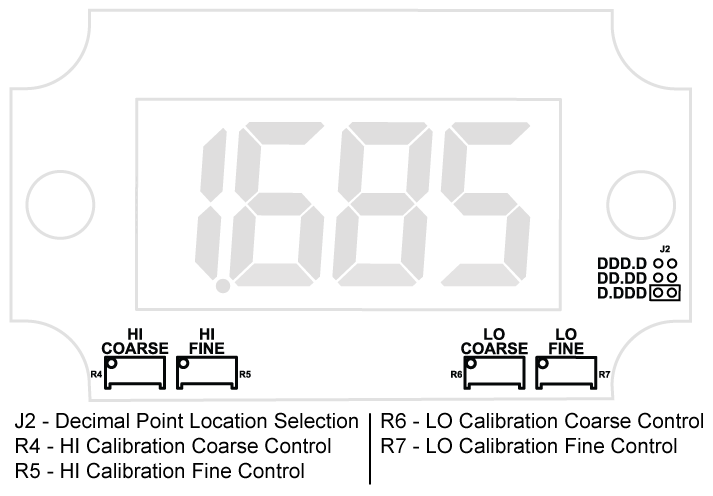

The PD685 can be seen from considerable distance in bright sunlight or dimly lit areas when the standard backlight feature is activated. The fact that this meter is loop-powered means that there is no need to run additional, costly power lines into a hazardous area. The meter gets all of the power it needs from the 4-20 mA loop and its 1 V (4 V with backlight) drop results in a minimal burden on the loop. The meter features a wide -40 to 75°C operating temperature range and is available with a ½" conduit hole in a location of your choice for easy installation. Calibration is a quick two-step process involving the adjustment of only two sets of coarse and fine, non-interacting potentiometers.

Features

- Type 4X, IP67 Loop-Powered Field-Mount Process Meter

- 4-20 mA Input

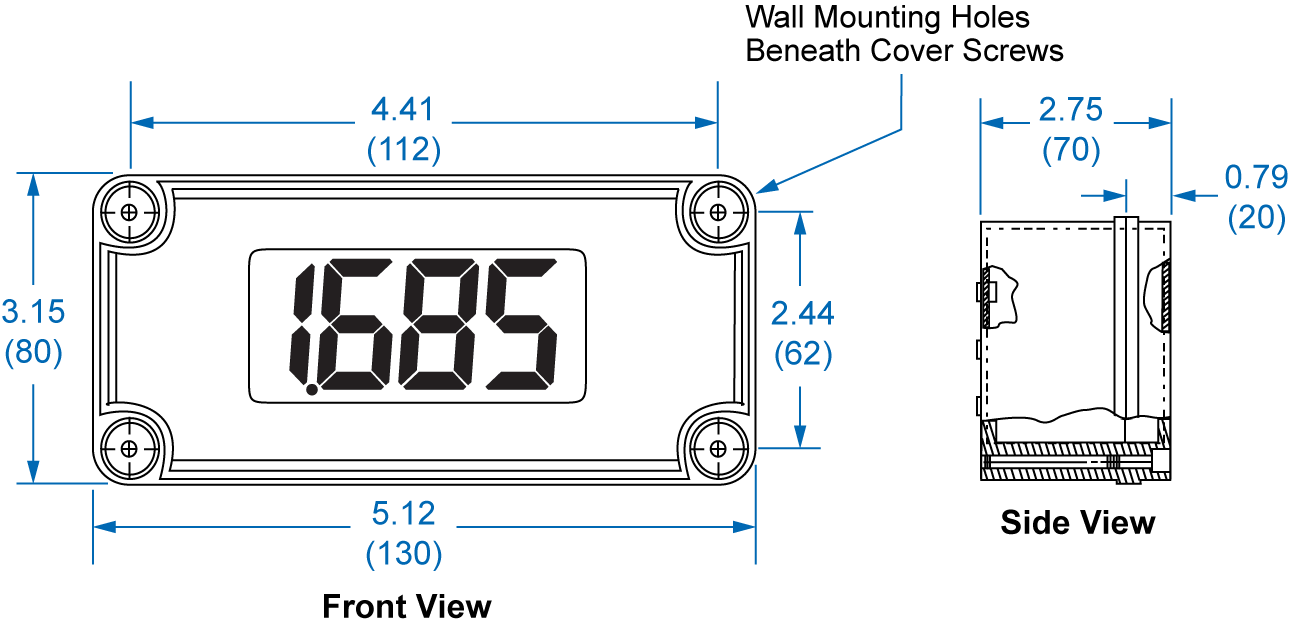

- 1.1" (28 mm) 3½ Digits LCD Display; -1999 to 1999

- 1 V Drop (4 V Drop with Backlight)

- HART® Protocol Transparent

- Loop-Powered Backlight Standard

- Operates from -40 to 75°C (-40 to 167°F)

- Coarse and Fine Zero & Span Potentiometer Adjustments for Easy Field Scaling

- Plastic Type 4X, IP67 Enclosure

- CSA, ATEX and IECEx Certified as Intrinsically Safe

- CE Marked

- Conformal Coated PCBs for Dust and Humidity Protection

- One ½" Conduit Hole (Rear, Top, Bottom or None)

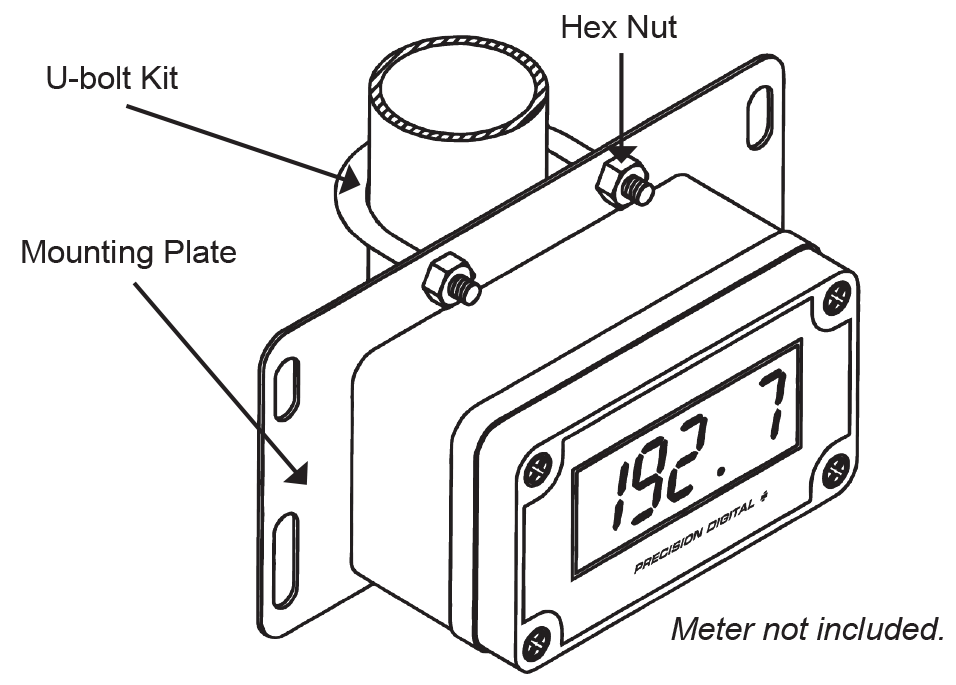

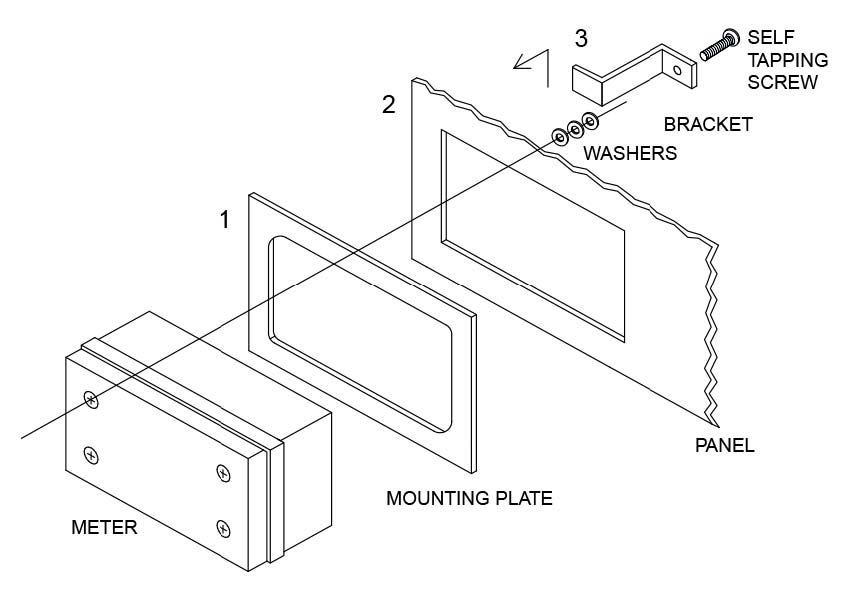

- Pipe & Panel Mounting Kits

- Stainless Steel Tag Available

- 3-Year Warranty

Why Use Loop-Powered Meters?

The most basic decision a user wishing to display a 4-20 mA signal on a digital display has to make is: should the meter be powered by line voltage or should it be powered by the 4-20 mA loop?

There are three main benefits of using loop-powered devices:

- No additional power required

- Easy wiring

- Additional digital displays can easily be added in the same loop

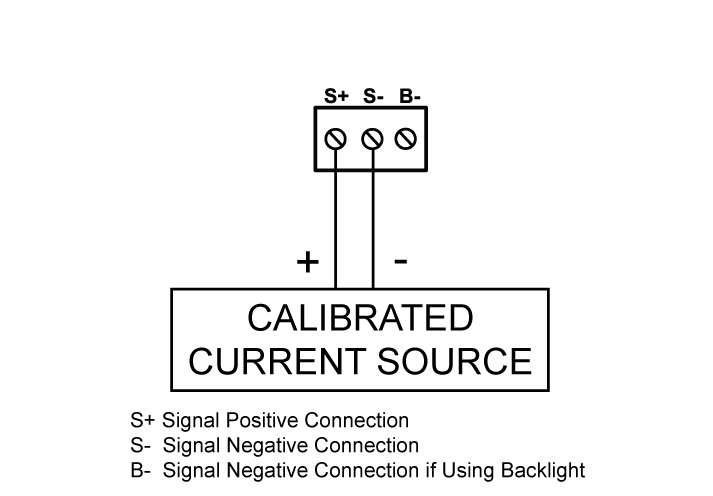

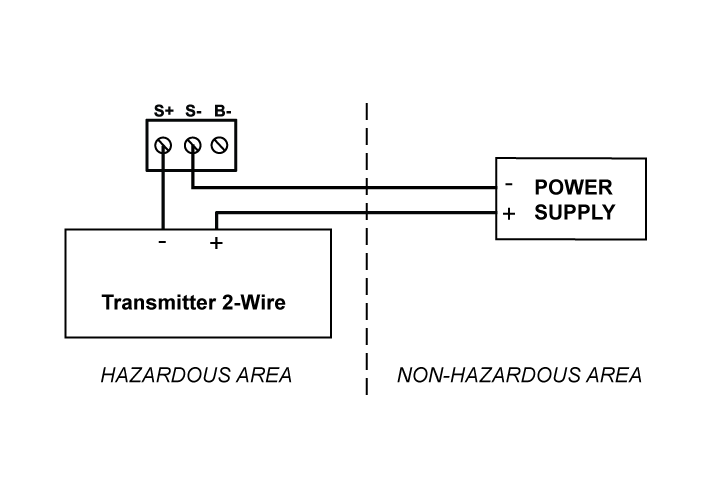

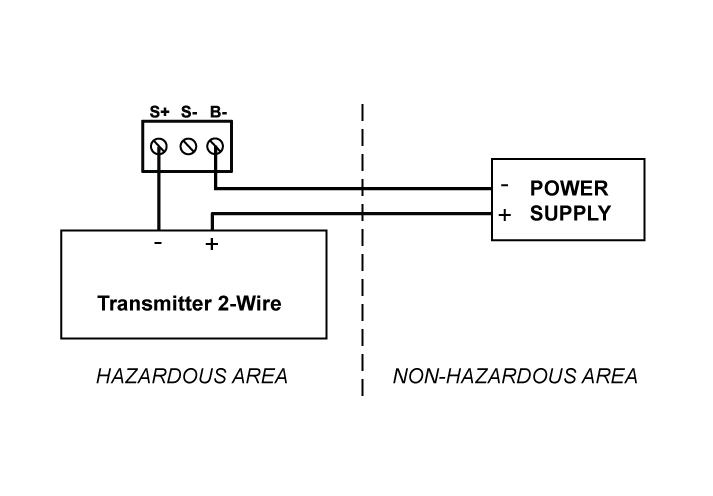

The following diagram illustrates how a loop-powered meter is wired. Notice there are only two connections made to the meter.

For more information on loop-powered meters, check out Fundamentals of Loop-Powered Devices and Loop-Powered vs Line-Powered Meters white papers.

Figure 3: Control Loop Connections (2-Wire)

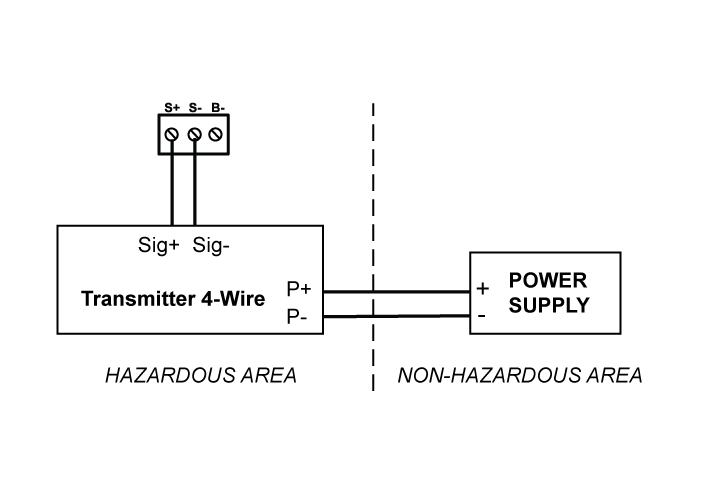

Figure 3: Control Loop Connections (2-Wire) Figure 4: Control Loop Connections

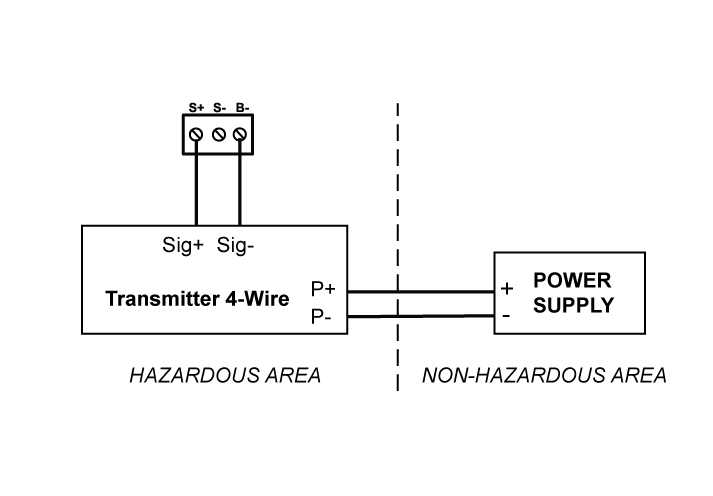

Figure 4: Control Loop Connections Figure 5: Control Loop Connections (4-Wire)

Figure 5: Control Loop Connections (4-Wire) Figure 6: Control Loop Connections

Figure 6: Control Loop Connections