General

Display: Upper display: 0.60" (15 mm) high. Lower display: 0.46" (12 mm) high. Both are 6 digits (-99999 to 999999), red LEDs.

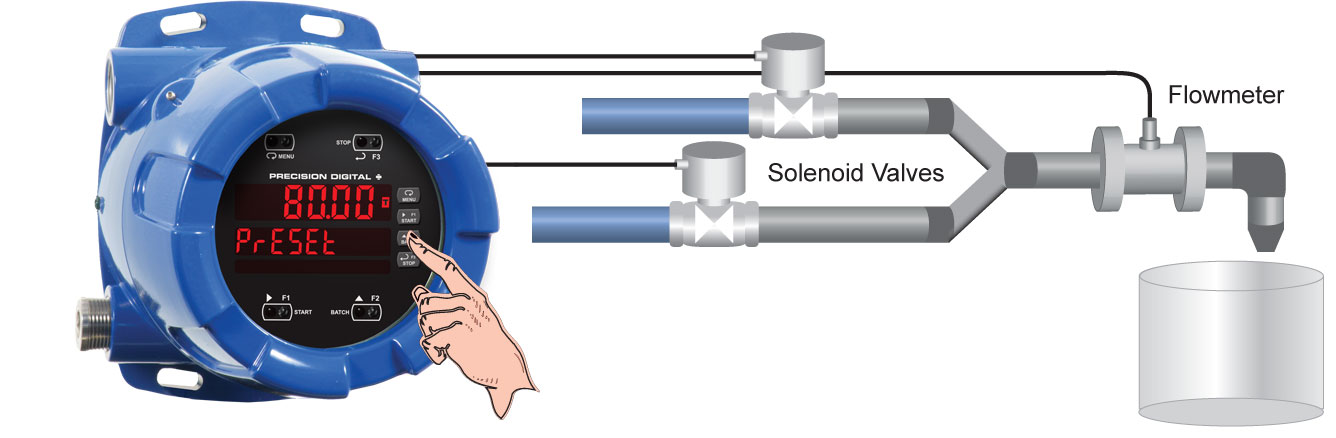

Default Display Assignment: The upper display shows batch total. The lower display shows rate with alternating units, and can be switched to show grand total, batch count, or preset with the STOP key.

Custom Display Assignment: The upper and lower displays may be assigned to rate, total, grand total, batch count, preset, set points, units (lower display only), alternating R & T, R & GT, preset & rate, max & min, or a Modbus display register. Any rate/total/grand total display may be programmed to alternate with a custom unit or tag.

Alternating Display: Displays alternate every 10 seconds when display is selected or the batch is paused.

Display Intensity: Eight user selectable intensity levels

Display Update Rate: 5/second (200 ms)

Overrange: Display flashes 999999

Underrange: Display flashes -99999

Programming Methods: Four front panel buttons, digital inputs, or PC and MeterView Pro software.

F4 Digital Input Contacts: 3.3 VDC on contact. Connect normally open contacts across F4 to COM.

F4 Digital Input Logic Levels: Logic High: 3 to 5 VDC; Logic Low: 0 to 1.25 VDC

Noise Filter: Programmable from 2 to 199 (0 will disable filter)

Filter Bypass: Programmable from 0.1 to 99.9% of calibrated span.

Recalibration: Recommended at least every 12 months.

Max/Min Display: Max (Peak) / min (Valley) readings reached by the process are stored until reset by the user or until power is cycled.

Password: Three programmable passwords restrict modification of programmed settings and two prevent resetting the totals.

Non-Volatile Memory: All programmed settings are stored in non-volatile memory for a minimum of ten years if power is lost.

Power Options: 85-265 VAC 50/60 Hz, 90-265 VDC, 20 W max, or optional model with 12-24 VDC ±10%, 15 W max.

Fuse: Required external fuse: UL Recognized, 5 A max, slow blow; up to 6 controllers may share one 5 A fuse.

Isolated Transmitter Power Supply: Terminals P+ & P-: 24 VDC ± 10%. Isolated from the input at >500 V. Jumper selectable for 24, 10, or 5 VDC supply (internal jumper J4). All models transmitter supply rated @ 25 mA max.

Normal Rejection Mode: Greater than 60 dB at 50/60 Hz

Isolation: 4 kV input/output-to-power line. 500 V input-to-output or output-to-P+ supply.

Overvoltage Category: Installation Overvoltage Category II: Local level with smaller transient overvoltages than Installation Overvoltage Category III.

Environmental:T6 Class operating temperature range: Ta = -55 to 60°C

T5 Class operating temperature range: Ta = -55 to 65°C

Storage temperature range: -55 to 85°C (-67 to 185°F)

Relative humidity: 0 to 90% non-condensing

Max Power Dissipation: Maximum power dissipation limited to 15.1 W

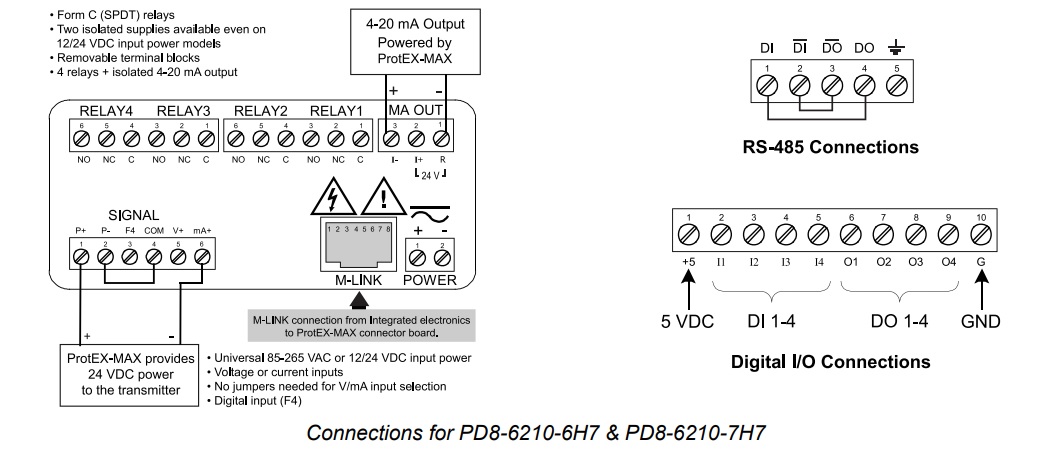

Connections: Removable screw terminal blocks accept 12 to 22 AWG wire, RJ45 for external relays, digital I/O, and serial communication adapters.

Weight: Aluminum: 14.7 lbs (6.67 kg); Stainless Steel: 23.5 lbs (10.66 kg)

Warranty: 3 years parts & labor

USB Connection: Compatibility: USB 2.0 Standard, Compliant

Connector Type: Micro-B receptacle

Cable: USB A Male to Micro-B Cable

Driver: Windows 98/SE, ME, 2000, Server 2003/2008, XP 32/64-Bit,

Vista 32/64-Bit, Windows 7 32/64-Bit, Windows 10 32/64-Bit

Power: USB Port

Analog Input

Inputs: Field selectable: 0-20, 4-20 mA, ±10 VDC (0-5, 1-5, 0-10 V), Modbus PV (Slave)

Accuracy: ±0.03% of calibrated span 1 count, square root & programmable exponent accuracy range: 10-100% of calibrated span

Temperature Drift: 0.005% of calibrated span/°C max from 0 to 65°C ambient, 0.01% of calibrated span/°C max from -40 to 0°C ambient

Signal Input Conditioning: Linear, square root, programmable exponent, or round horizontal tank volume calculation.

Multi-Point Linearization: 2 to 32 points

Programmable Exponent: 1.0001 to 2.9999

Low-Flow Cutoff: 0-999999 (0 disables cutoff function)

Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd.

Calibration Range:| Input Range | Minimum Span Input 1 & 2 |

| 4-20 mA | 0.15 mA |

| 10 V | 0.10 V |

An error message will appear if input 1 and input 2 signals are too close together.Input Impedance: Voltage ranges: greater than 1 MΩ.

Current ranges: 50 - 100 Ω (depending on resettable fuse impedance).

Input Overload: Current input protected by resettable fuse, 30 VDC max. Fuse resets automatically after fault is removed.

HART Transparency: Analog input will not interfere with existing HART communications on the wired 4-20 mA signal

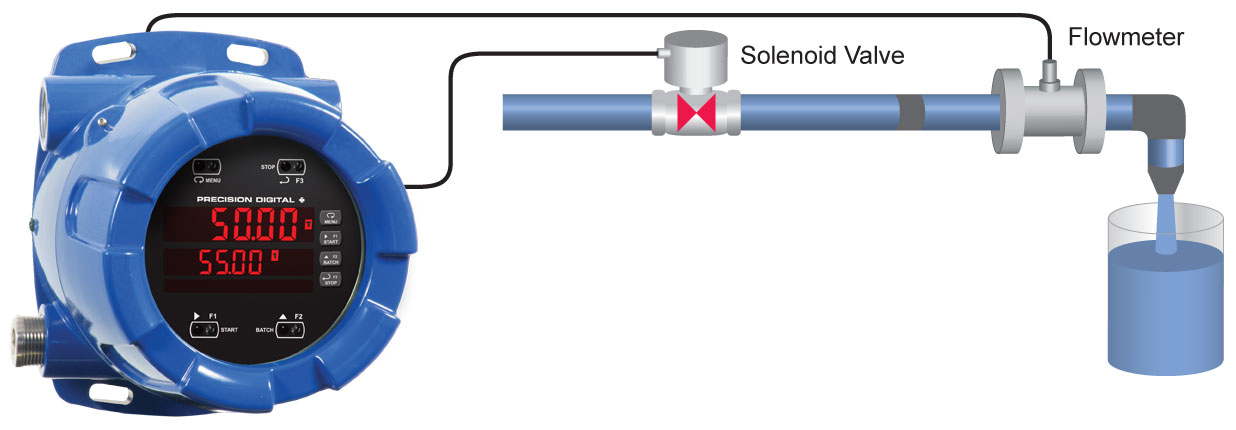

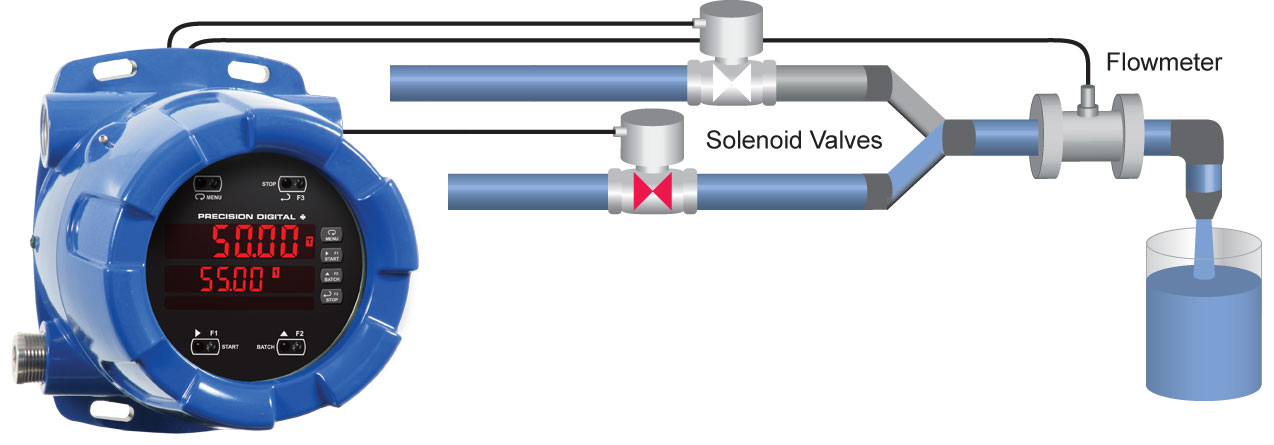

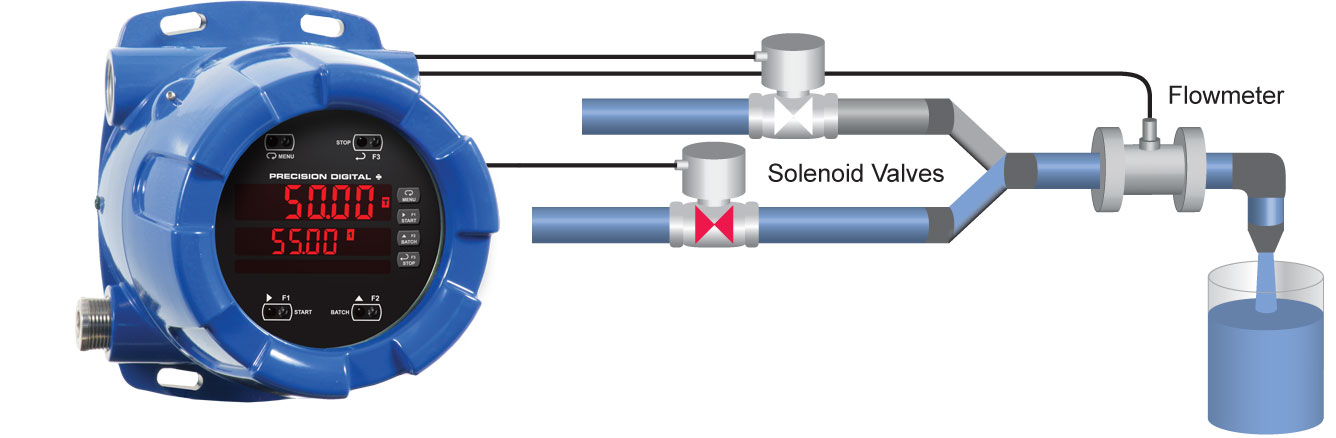

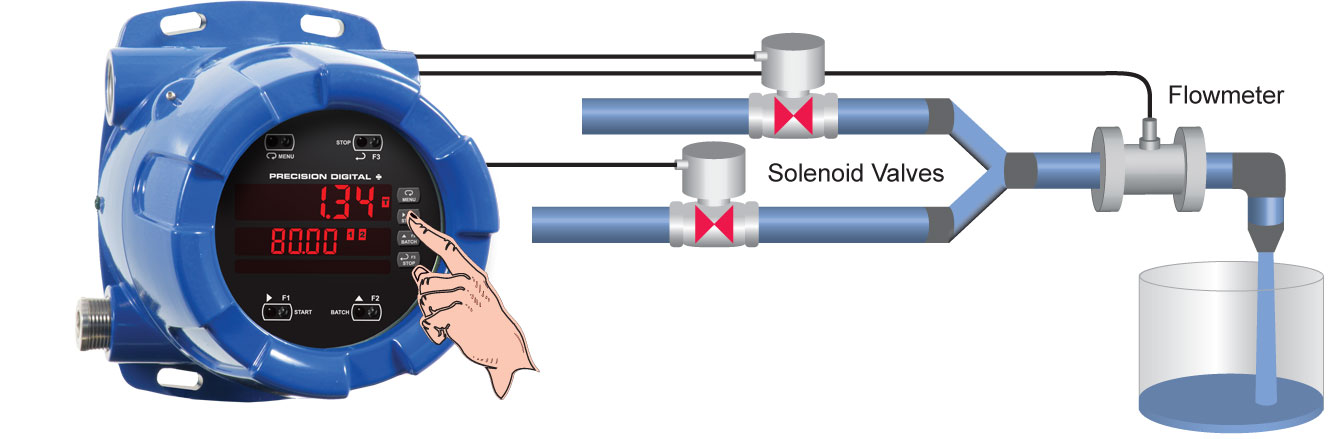

Batch Controller

Rate Display Indication: 0 to 999999, lead zero blanking. "R" LED illuminates while displaying rate.

Total Displays & Grand Total Overflow: 0 to 999,999; automatic lead zero blanking. "T" LED is illuminated while displaying batch total and "GT" for grand total. Up to 999,999,999 with total-overflow feature. "

" is displayed to the left of grand total overflow and

LED is illuminated.

Batch Total Decimal Point: Up to five decimal places or none: d.ddddd, dd.dddd, ddd.ddd, dddd.dd, ddddd.d, or dddddd. Total decimal point is independent of rate decimal point.

Totalizer: Calculates total based on rate and field programmable multiplier to display total in engineering units. Time base must be selected according to the time units in which the rate is displayed.

Total Conversion Factor: 0.00001 to 999,999

Batch Preset: 0.00001 to 999,999 based on batch total decimal point.

Automatic Batch Restart Delay: 00000.1 to 999.9 seconds. The batch will automatically restart after completion of the last batch.

Grand Total Rollover: Totalizer rolls over when display exceeds 999,999,999. Relay status reflects the display value.

Grand Total Alarms: Up to seven, user selectable under Setup menu. Any set point can be assigned to grand total and may be programmed anywhere in the range of the controller for grand total alarm indication.

Note that Relay 1 should always be assigned to batch control (total).

Grand Total Reset: Via front panel button, external contact closure on digital inputs, automatically via user selectable preset value and time delay, or through serial communications.

Grand Total Reset Password: A grand total password may be entered to prevent resetting the grand total from the front panel.

Non-Resettable Grand Total: The grand total can be programmed as a non-resettable total by entering the password "050873".

Caution: Once the Grand Total has been programmed as "non-resettable" the feature cannot be disabled.Relays

Rating: 4 SPDT (Form C) internal and/or 4 SPST (Form A) external; rated 3 A @ 30 VDC and 125/250 VAC resistive load; 1/14 HP (≈ 50 W) @ 125/250 VAC for inductive loads

Noise Suppression: Noise suppression is recommended for each relay contact switching inductive loads.

Relay Assignment: Relays may be assigned to batch control, sampling, rate, or grand total alarms.

Preclose: 0-100% of batch size, individually user programmable for each additional batch control relay beyond the first.

Alarm Deadband: 0-100% of span, user programmable

High or Low Alarm: User may program any alarm for high or low trip point. Unused alarm LEDs and relays may be disabled (turned off).

Batching Relay Operation: Single or (2 to 8) multi-relay batching with optional preclose for multi-stage operation. Each additional relay may be programmed with an individual preclose value.

Alarm Relay Operation: Automatic (non-latching), latching (requires manual acknowledge), sampling (based on rate or grand total), pump alternation control (2 to 8 relays), off (disable unused relays), and manual on/off control mode. Alarms are active only when the batch is running.

Alarm Relay Reset: User selectable via front buttons, digital inputs, or PC

1. Automatic reset only (non-latching), when input passes the reset point or total is reset to zero.

2. Manual reset only, when batch is stopped (latching).

3. Manual reset only after alarm condition has cleared (latching)

Note: Front panel button or digital input may be assigned to acknowledge relays programmed for manual reset. This replaces one of the standard batch control function keys. Only the PAUSE/STOP key function is possible during a batch process, so manual reset may only be done when thecontroller is in STOP mode.Deadband: 0-100% of span, user programmable

Time Delay: 0 to 999.9 seconds, on & off relay time delays. Programmable and independent for each relay.

Fail-Safe Operation: Programmable and independent for each relay.

Note: Relay coil is energized in non-alarm condition. In case of power failure, relay will go to alarm state.Auto Initialization: When power is applied, relays will reflect the state of the input. Alarms are active only when the batch is running.

Isolated 4-20 mA Transmitter Output

Output Source: Rate/process, total, grand total, max, min, set points 1-8, manual control setting, or Modbus input

Scaling Range: 1.000 to 23.000 mA for any display range

Calibration: Factory calibrated: 4.000 to 20.000 = 4-20 mA output

Analog Output Programming: 23.000 mA maximum for all parameters: Overrange, underrange, max, min, and break

Accuracy: ±0.1% FS ±0.004 mA

Temperature Drift: 0.4 µA/°C max from 0 to 65°C ambient, 0.8 µA/°C max from -40 to 0°C ambient Note: Analog output drift is separate from input drift.

Isolated Transmitter Power Supply: Terminals I+ & R: 24 VDC ± 10%. Isolated from the input at >500 V. May be used to power the 4-20 mA output or other devices. All models @ 25 mA max.

External Loop Power Supply: 35 VDC maximum

Output Loop Resistance:| Power supply | Minimum | Maximum |

| 24 VDC | 10 Ω | 700 Ω |

| 35 VDC (external) | 100 Ω | 1200Ω |

Serial Communications

Compatability: EIA-485

Connectors: Removable screw terminal connector

Max Distance: 3,937' (1,200 m) max

Status Indication: Separate LEDs for Power (P), Transmit (TX), and Receive (RX)

Protocol: Modbus® RTU

Controller Address/Slave ID: 1 - 247

Baud Rate: 300 - 19,200 bps

Transmit Time Delay: Programmable between 0 and 199 ms or transmitter always on for RS-422 communication

Data: 8 bit (1 start bit, 1 or 2 stop bits)

Parity: Even, odd, or none with 1 or 2 stop bits

Byte-to-Byte Timeout: 0.01 - 2.54 seconds

Turn Around Delay: Less than 2 ms (fixed)

Note: Refer to the PD6000/PD7000 Modbus Register Tables located in the documentation section of this page.

Digital Inputs and Outputs

Channels: 4 digital inputs & 4 digital outputs per module

System: One expansion module may be added for a total of 8 inputs & 8 outputs

Note: The jumper located between the RJ45 connectors must be removed on the expansion module. Digital Input Logic: High: 3 to 5 VDC;

Low: 0 to 1.25 VDC

Digital Output Logic: High: 3.1 to 3.3 VDC;

Low: 0 to 0.4 VD

Source Current: 10 mA maximum output current

Sink Current: 1.5 mA minimum input current

+5 V Terminal: To be used as pull-up for digital inputs only. Connect normally open pushbuttons across +5 V & DI 1-4.

Warning: DO NOT use +5 V terminal (pin 1) to power external devices.

Function Assignment: The on-board digital inputs (1-4) are designed to mimic the behavior of the front panel buttons (Menu, F1, F2, & F3). If you wish to change their behavior, re-assign F1-F3 to the desired function, then change the corresponding digital input to match.

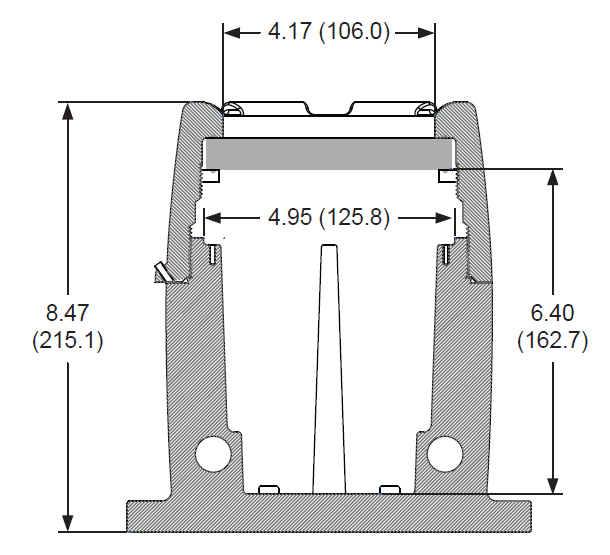

Enclosure

| Material | -AL Models: ASTM A413 LM6 die-cast aluminum, copper-free, enamel coated

-SS Models: ASTM A743 CF8M investment-cast 316 stainless steel |

| Gasket | Fluoroelastomer |

| Rating | NEMA 4X, IP68 Explosion-proof |

| Color | -AL: Blue

-SS: Silver |

| Window | Borosilicate glass |

| Conduits | Four ¾" NPT threaded conduit openings |

| Conduit Stopping Plugs | Sold separately |

| Flanges | Two built-in flanges for wall and pipe mounting. |

| Tamper-Proof Seal | Cover may be secured with tamper-proof seal. |

| Overall Dimensions | 6.42" x 7.97" x 8.47" (W x H x D)

(163 mm x 202 mm x 215 mm) |

| Weight | AL: 14.7 lbs (6.67 kg)

SS: 23.5 lbs (10.66 kg) |

| ATEX | Flameproof

II 2GD II 2GD

Ex db IIC Gb

Ex tb IIIC Db

IP66/IP68

Tamb: -55°C to +85°C

Certificate No.: Sira 19ATEX1252U |

| IECEx | Flameproof and dust protection

Ex db IIC Gb

Ex tb IIIC Db

IP66/IP68

Tamb: -55°C to +85°C

Certificate No.: IECEx SIR 19.0075U |

| CSA | Class I, Division 1, Groups A, B, C, D

Class II, Division 1, Group E, F, G

Class III

Ex db IIC Gb

Ex tb IIIC Db

Class I, Zone 1, AEx db IIC Gb

Zone 21, AEx tb IIIC Db

IP66/IP68/TYPE 4X

Tamb: -55°C to +85°C

Certificate No.: 80011200 |

| UL | Class I, Division 1, Groups A, B, C, D

Class II, Division 1, Groups E, F, G

Class III

Class I, Zone 1, AEx db IIC Gb

Zone 21, AEx tb IIIC

Ex db IIC Gb

Ex tb IIIC Db

IP66/IP68/TYPE 4X

Tamb: -55°C to +85°C

Certificate Number: E518920 |

| Note: The above approvals are for the enclosure only. See below for approvals on the entire instrument. |

General Compliance Information

Electromagnetic Compatibility

| Emissions | EN 55022

Class A ITE emissions requirements |

| Radiated Emissions | Class A |

| AC Mains Conducted Emissions | Class A |

| Immunity | EN 61326-1

Measurement, control, and laboratory equipment

EN 61000-6-2

EMC heavy industrial generic immunity standard |

| RFI - Amplitude Modulated | 80 -1000 MHz 10 V/m 80% AM (1 kHz)

1.4 - 2.0 GHz 3 V/m 80% AM (1 kHz)

2.0 - 2.7 GHz 1 V/m 80% AM (1 kHz) |

| Electrical Fast Transients | ±2kV AC mains, ±1kV other |

| Electrostatic Discharge | ±4kV contact, ±8kV air |

| RFI - Conducted | 10V, 0.15-80 MHz, 1kHz 80% AM |

| AC Surge | ±2kV Common, ±1kV Differential |

| Surge | 1KV (CM) |

| Power-Frequency Magnetic Field | 30 A/m 70%V for 0.5 period |

| Voltage Dips | 40%V for 5 & 50 periods

70%V for 25 periods |

| Voltage

Interruptions | <5%V for 250 periods |

| Note: Testing was conducted on meters with cable shields grounded

at the point of entry representing installations designed to optimize

EMC performance. |

Product Ratings and Approvals

| CSA | Class I, Division 1, Groups B, C, D

Class II, Division 1, Groups E, F, G

Class III, Division 1

Class I Zone 1 Ex db IIC

Zone 21 Ex tb IIIC T90°C

-55°C < Tamb. < +60° C; Temperature Code T6

-55°C < Tamb. < +65° C; Temperature Code T5

Enclosure Type 4X & IP66 / IP68

Certificate Number: 2531731 |

| ATEX | II 2 G D

Ex db IIC T* Gb

Ex tb IIIC T90°C Db IP68

Ta = -55°C to +*°C

*T6 = -55°C to +60°C

*T5 = -55°C to +65°C

Certificate Number: Sira 12ATEX1182X

|

| IECEx | Ex db IIC T* Gb

Ex tb IIIC T90°C Db IP68

Ta = -55°C to +*°C

*T6 = -55°C to +60°C

*T5 = -55°C to +65°C

*T5 = -55°C to +65°C

Certificate Number: IECEx SIR 12.0073X

|

ATEX/IECEx Specific Conditions of Use:- The equipment label and epoxy coating may

generate an ignition-capable level of electrostatic

charges under certain extreme conditions. The

user should ensure that the equipment is not

installed in a location where it may be subjected

to external conditions (such as high-pressure

steam) which might cause a build-up of

electrostatic charges on non-conducting

surfaces. Additionally, cleaning of the equipment

should be done only with a damp cloth.

- Flameproof joints are not intended to be repaired.

- All entry closure devices shall be suitably certified

as “Ex d”, “Ex t” and “IP66/68” as applicable.

Suitable thread sealing compound (non-setting,

non-insulating, non-corrosive, not solvent based,

suitable for the ambient rating) must be used at

the NPT conduit entries to achieve the IPx8

rating while maintaining the Ex protection

concept.

Year of ConstructionThis information is contained within the serial number

with the first four digits representing the year and

month in the YYMM format.

For European Community:The ProtEX-MAX must

be installed in accordance with the ATEX directive

2014/34/EU, and the product certificate Sira

12ATEX1182X.