Features

- Fully-Approved Explosion-Proof Loop-Powered Meter

- 4-20 mA Input with ±0.03% Accuracy

- 3.0 Volt Drop (6.0 Volt Drop with Backlight)

- Easy Field Scaling in Engineering Units without Applying an Input

- 0.7" (17.8 mm) 5 Digits Main Display

- 0.4" (10.2 mm) 7 Alphanumeric Characters Secondary Display

- Display Mountable at 0°, 90°, 180°, & 270°

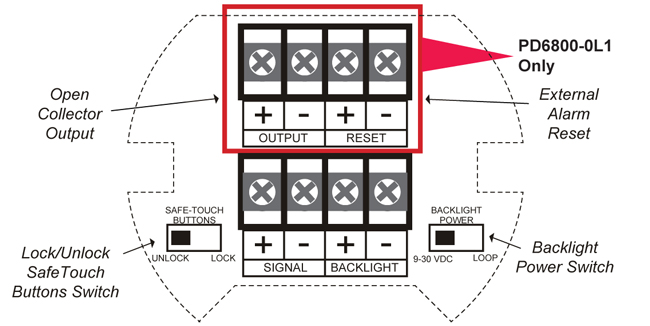

- SafeTouch Through-Glass Button Programming

- HART® Protocol Transparent

- Loop or External DC-Powered Backlight Standard

- Operating Temperature Range: -40 to 75°C (-40 to 167°F)

- Installation Temperature Range: -55 to 75°C (-67 to 167°F)

- CSA Certified as Explosion-Proof / Dust Ignition-Proof / Flame-Proof

- ATEX and IECEx Certified as Explosion-Proof

- Conformal Coated PCBs for Dust and Humidity Protection

- Password Protection

- 32-Point Linearization, Square Root Extraction and Programmable Exponent Function

- Wide Viewing Angle

- Built-In Flange for Wall or Pipe Mounting

- Explosion-Proof, IP68, NEMA 4X Die-Cast Aluminum & Stainless Steel Enclosures

- Two 3/4" NPT or M20 Conduit Openings

- 2" U-Bolt Kit Available

- 3-Year Warranty

Why Use Loop-Powered Meters?

The most basic decision a user wishing to display a 4-20 mA signal on a digital display has to make is: should the meter be powered by line voltage or should it be powered by the 4-20 mA loop?

There are three main benefits of using loop-powered devices:

- No additional power required

- Easy wiring

- Additional digital displays can easily be added in the same loop

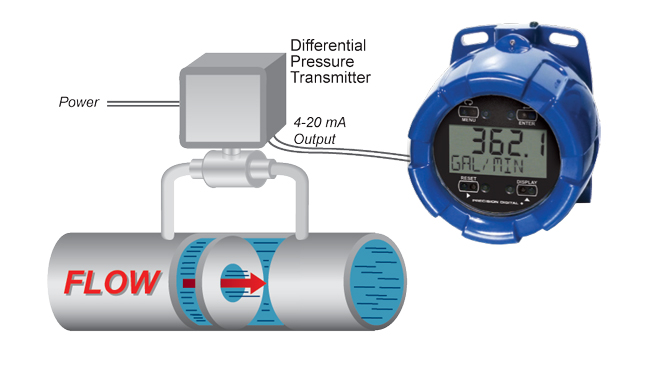

The following diagram illustrates how a loop-powered meter is wired. Notice there are only two connections made to the meter.

For more information on loop-powered meters, check out Fundamentals of Loop-Powered Devices and Loop-Powered vs Line-Powered Meters white papers.

Overview

Hazardous Area Loop-Powered Meter

The PD6800 is a rugged, full-featured, explosion-proof loop-powered meter ideal for demanding applications in hazardous areas or in the harshest environmental conditions.

The product is CSA Certified as Explosion-Proof / Dust Ignition-Proof / Flame-Proof and ATEX & IECEx Certified as Explosion-Proof. It is available in either an aluminum or stainless steel enclosure with ¾" or M20 conduit connections. It will operate down to -40°C and is approved for installation in areas where the temperature gets as cold as -55°C, however the display will cease functioning.

The meter derives all of its power from the 4-20 mA loop, thus making installation a simple matter of wiring the instrument into the existing loop. No external power is required. Programming is performed using the four SafeTouch through-glass buttons and can be done without removing the cover. In addition, the meter can be scaled with or without a calibration signal.

The backlit LCD display consists of two lines with the addition of a 20-segment bargraph on the PD6800-0L1. The main line of the display has five full digits and is used to display the process variable. The secondary line has seven alphanumeric characters and is used for a tag, engineering units, or displaying the input in different units (for the PD6800-0L1). For instance, on the PD6800-0L1, the top line could display the height of the tank in feet and the bottom line could display the same input in gallons. The bargraph provides a quick visual of the current state of the process variable. The backlight makes the display visible under any lighting condition and can be powered from either the 4-20 mA loop or from a separate DC power supply.