The PD662 NEMA 4X, CSA Certified loop-powered meter is perfect for applications where a simple, inexpensive display is required and AC power is not available. The PD662 derives all its power from the 4-20 mA loop, including its backlight feature. It can be easily scaled in the field using four push buttons; with or without applying an actual calibration signal. The PD662’s display will read up to 2999; we call this 3½+ digits! The PD662 is housed in a rugged NEMA 4X enclosure and is provided with one ½" NPT pipe conduit hole.

Features

- NEMA 4X, IP66 Loop-Powered Field-Mount Process Meter

- 4-20 mA Input

- 1.7 Volt Drop (3.7 Volt Drop with Backlight)

- Easy Field Scaling in Engineering Units without Applying an Input

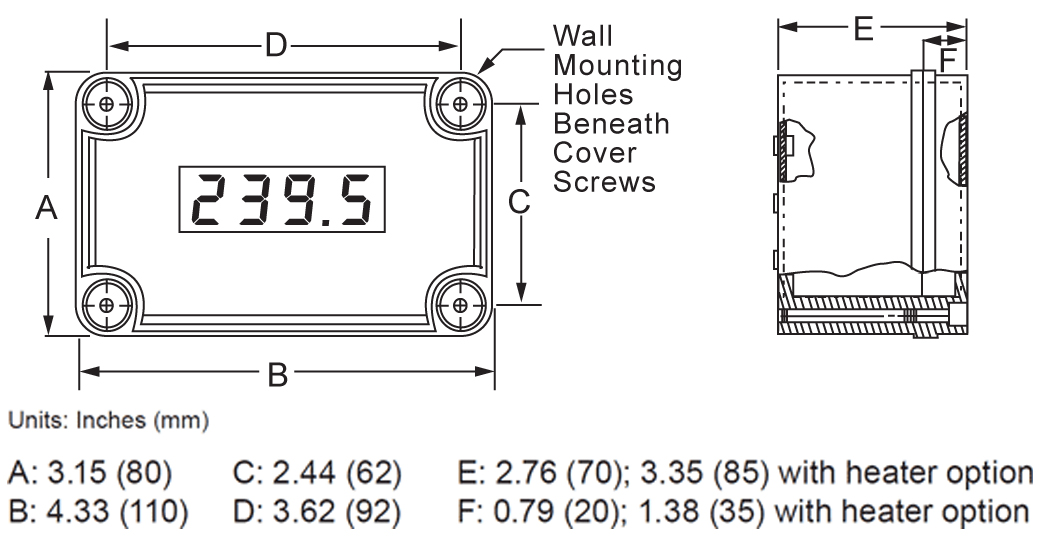

- 0.6" (15.2 mm) 3½+ Digits LCD Display; -1999 to 2999

- HART® Protocol Transparent

- Loop-Powered Backlight

- CSA Certified Operating Temperature Range: -40 to 75°C (-40 to 167°F)

- Four Internal Buttons for Easy Field Scaling

- Max/Min Display

- Programmable Noise Filter

- 32-Point Linearization & Square Root Extraction

- Plastic NEMA 4X, IP66 Enclosure

- Conformal Coated PCBs for Dust and Humidity Protection

- One ½" Conduit Hole in Enclosure

- Stainless Steel Pipe & Panel Mounting Kits Available

- Stainless Steel Tag Available

- 3-Year Warranty

Why Use Loop-Powered Meters?

The most basic decision a user wishing to display a 4-20 mA signal on a digital display has to make is: should the meter be powered by line voltage or should it be powered by the 4-20 mA loop?

There are three main benefits of using loop-powered devices:

- No additional power required

- Easy wiring

- Additional digital displays can easily be added in the same loop

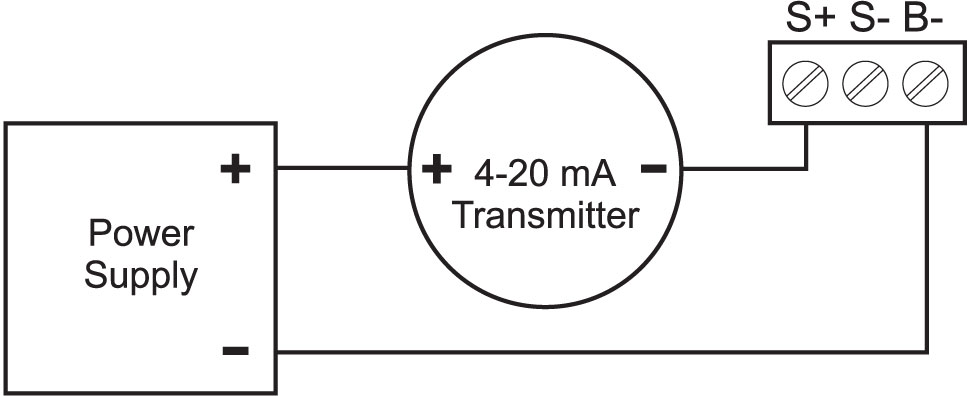

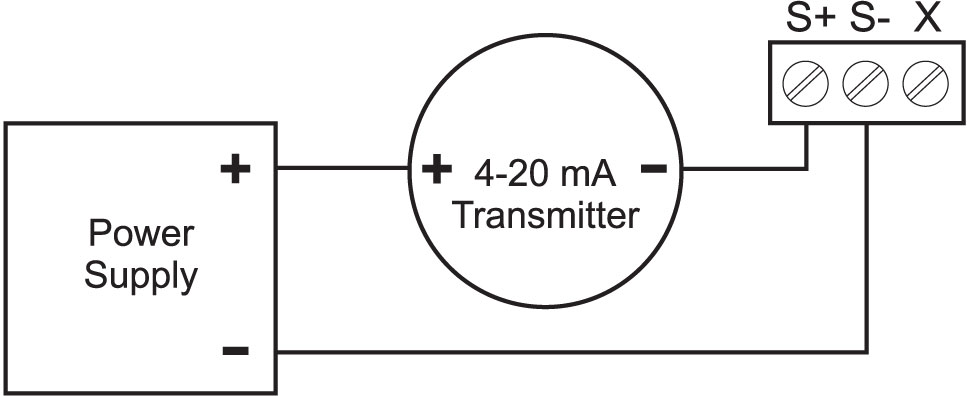

The following diagram illustrates how a loop-powered meter is wired. Notice there are only two connections made to the meter.

For more information on loop-powered meters, check out Fundamentals of Loop-Powered Devices and Loop-Powered vs Line-Powered Meters white papers.