The SuperNova PD500 Series of PID Process & Temperature Controllers are a complete line of PID and on/off controllers. Available in popular 1/4, 1/8 (V), and 1/16 DIN sizes, and with a shallow depth behind panel of only 2.5" (63 mm) they are easy to fit into almost any panel, product, or enclosure.

Voltage, current (with external resistor), and direct temperature thermocouple and RTD inputs make them an excellent choice for any control application requiring easy to change, visible set points.

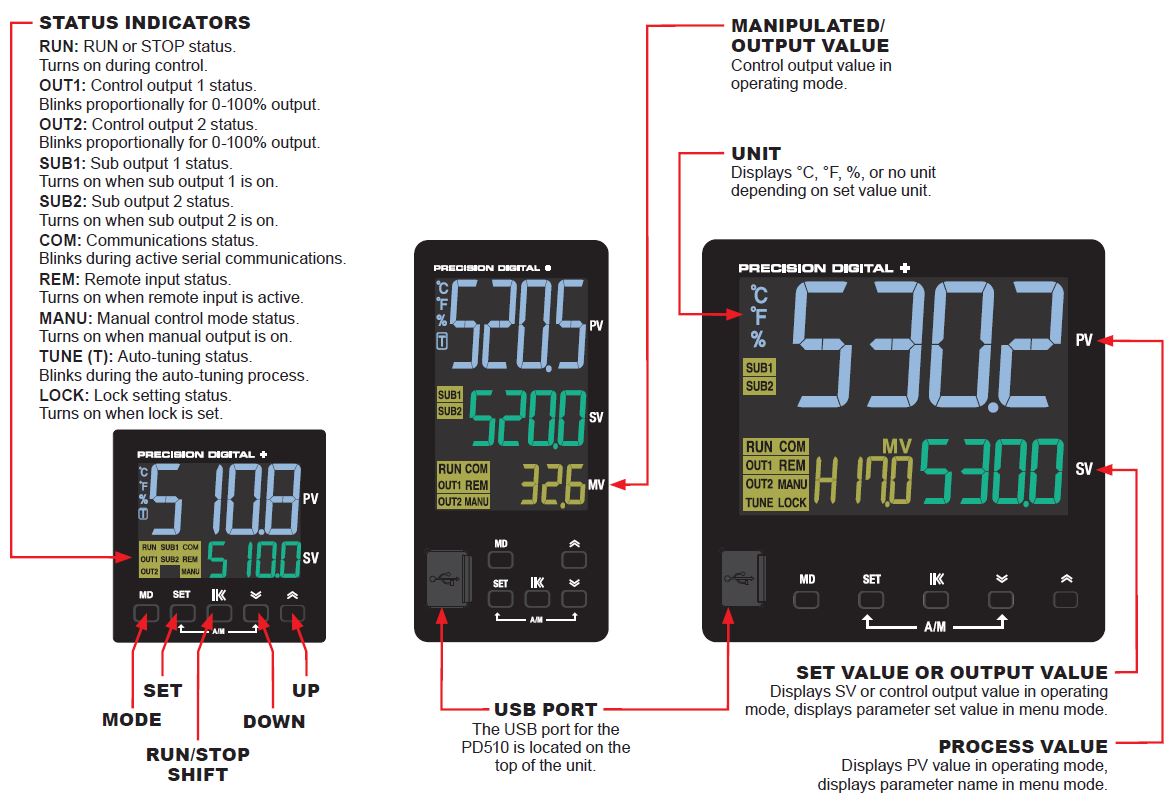

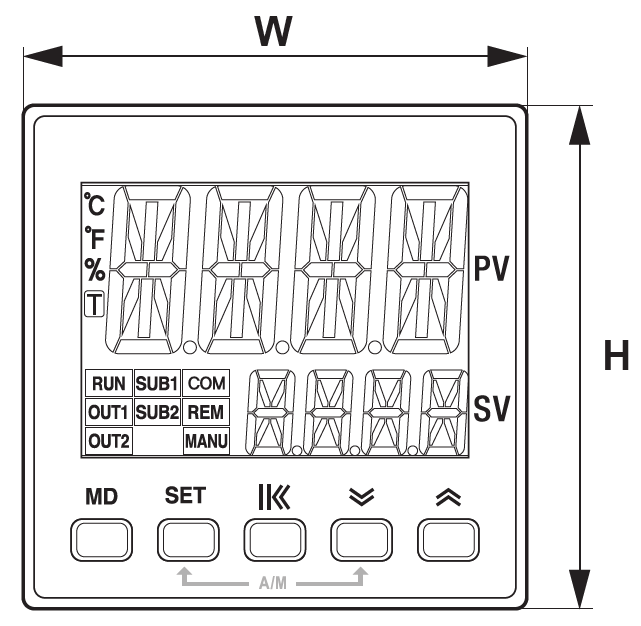

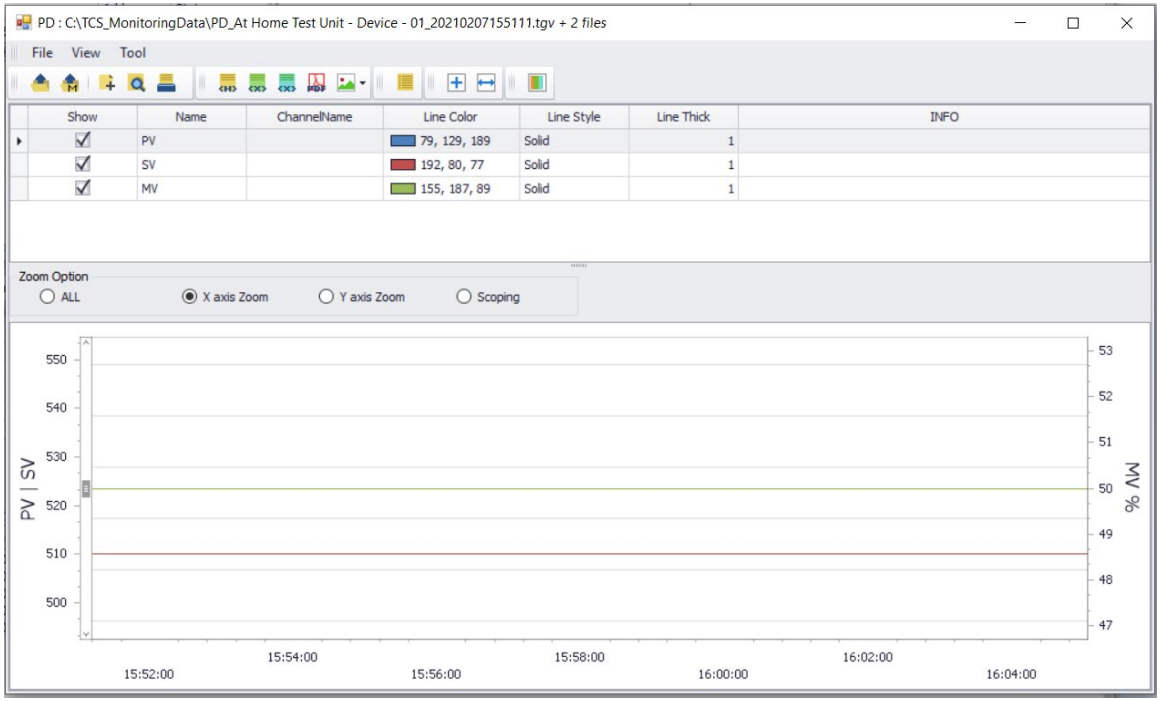

This modern line of controllers shows the process variable (PV), set value (SV), and manipulated value (output level%, MV) on a striking reverse polarity LCD screen. The front panel has indicators for RUN, COM, OUT 1 & 2, REM, MANU, TUNE, and LOCK. Indicators for units (˚C, ˚F, %, or none) can also be displayed.

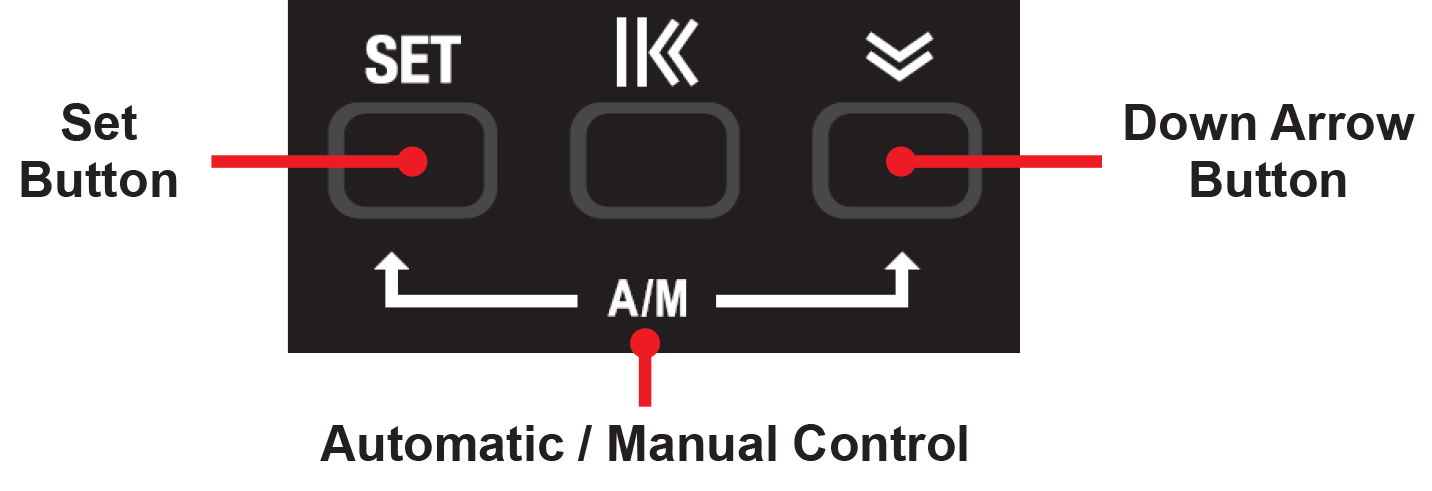

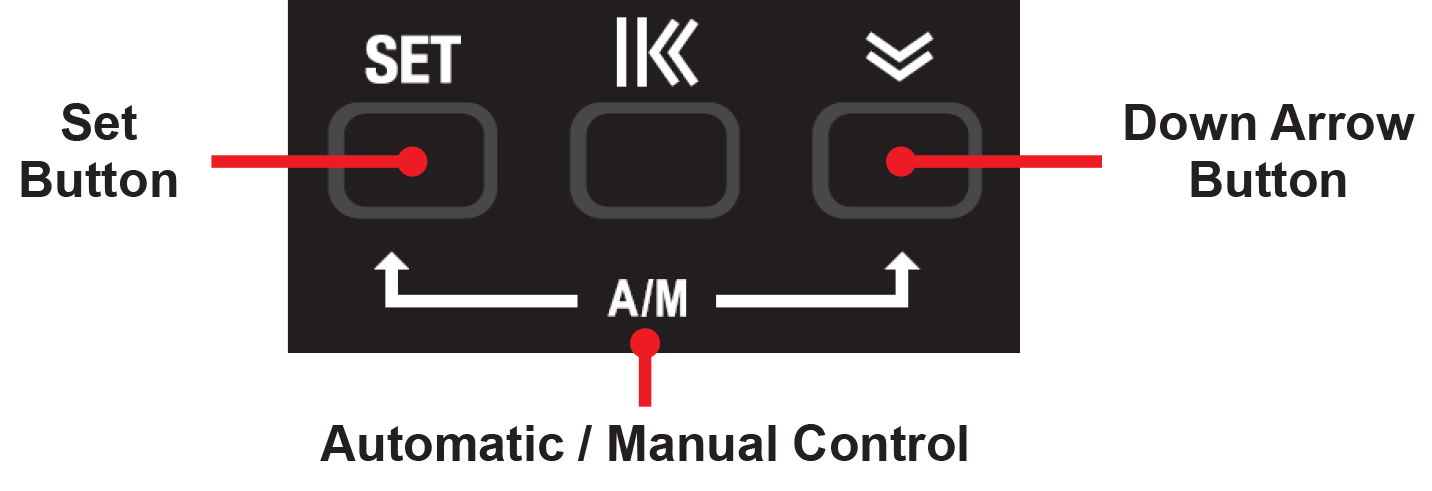

. A graphic on the front panel indicates that these buttons

control the Auto/Manual (A/M) function:

. A graphic on the front panel indicates that these buttons

control the Auto/Manual (A/M) function:

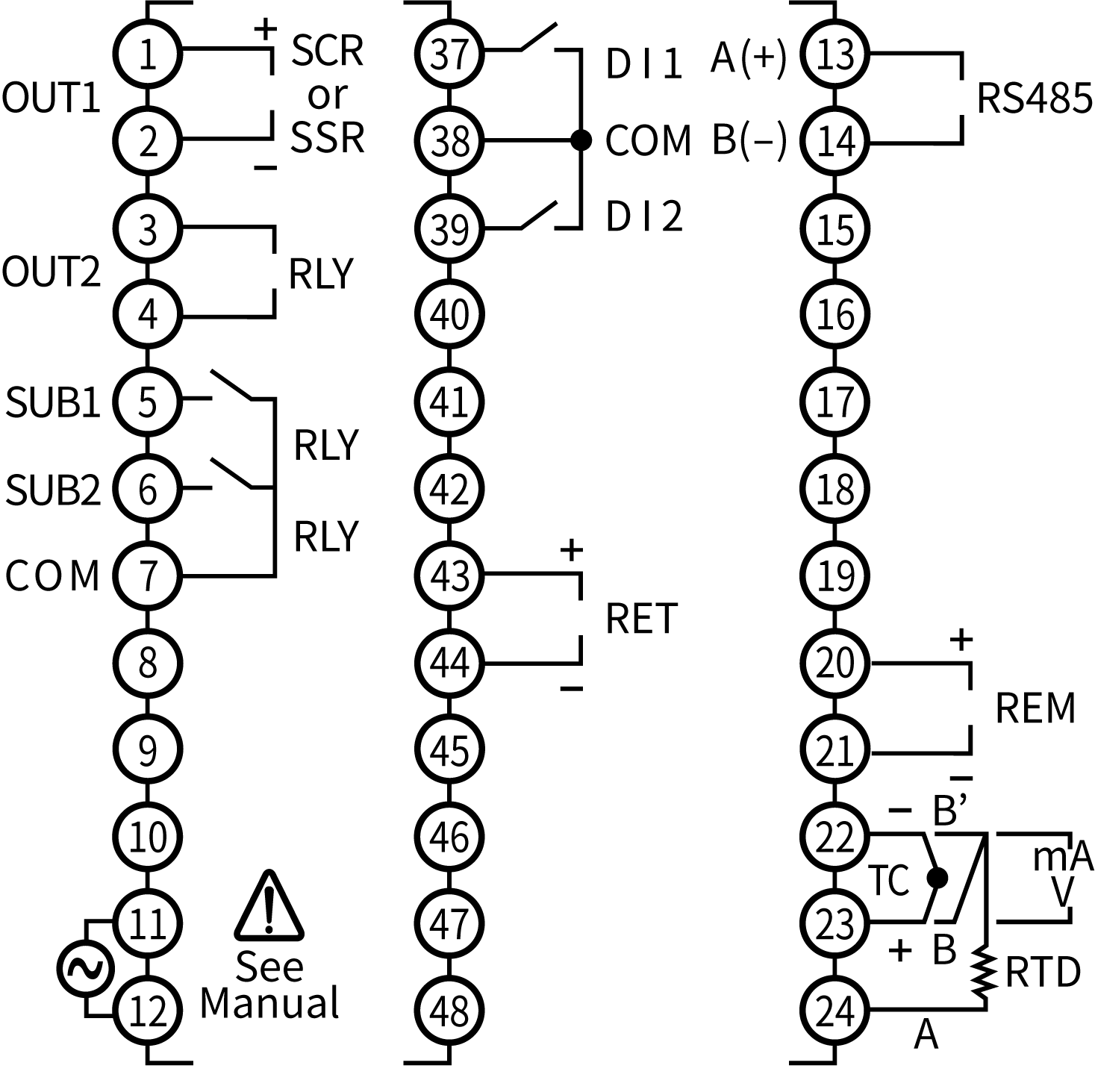

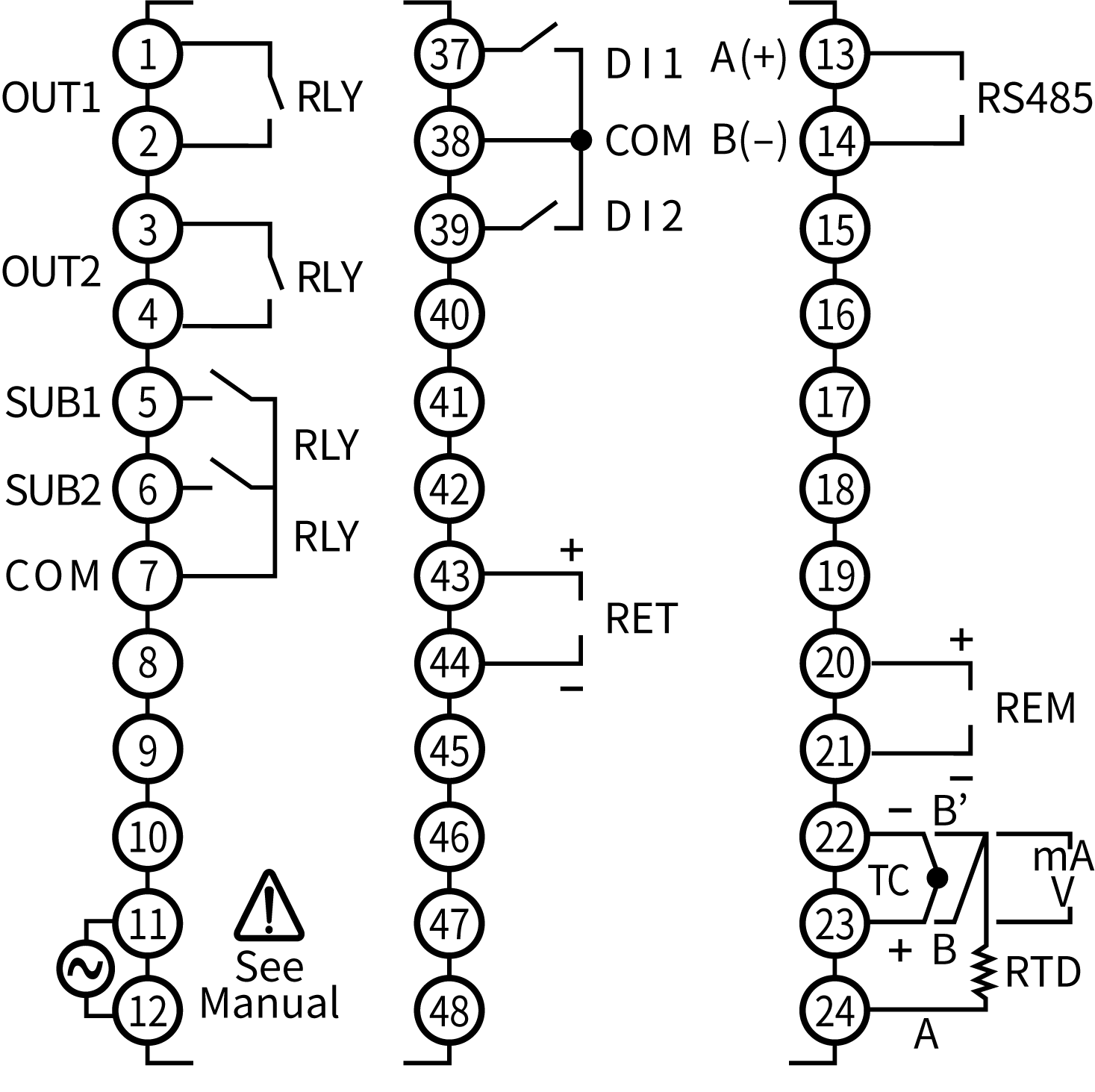

The main control outputs can be a 4-20 mA (SCR), voltage pulse (SSR), or relay output. A secondary control output relay is standard, which allows for one or two direction SV control (i.e., heating and cooling).

Two alarm relays increase the utility of the SuperNova controller. The relays can be used for alarm or simple control applications. The alarms may relate directly to the process variable, or be based on deviation from the current set value.

A 4-20 mA retransmit option is available to retransmit the process variable, set value, or output level. This is especially useful for temperature inputs like thermocouples and RTDs. Other options include a secondary 4-20 mA input to remotely control the set value, and RS-485 for Modbus communication.

A mini-USB port may be used for a direct PC connection to run the SuperNova software for monitoring, programming, and data logging. This USB port is located on the rear behind the panel for PD510 1/16 DIN models, and on the front behind an IP65 rubber tab on PD520 and PD530 1/8 and 1/4 DIN models.

Features

- 1/16, 1/8 (V), and 1/4 DIN Auto-Tuning PID Process & Temperature Controllers

- Reverse Polarity Three-Color LCD: -1999 to 9999

- Thermocouple and RTD Inputs

- DC Voltage and Current Inputs (1-5 V, 0-5 V, 0-10 V, 0-50 mV, 0-100 mV; 4-20 mA with Resistor)

- 250 Ω Resistor(s) Included Standard

- High Accuracy Auto-Tuning PID

- High Durability IP65 Front with Hard Plastic Pushbuttons

- Large Easy to Read 14-Segment PV Display up to 1.1" (29 mm)

- Input Power 100-240 VAC

- Heating, Cooling, and Heating & Cooling Control

- Primary Control Output Options: 4-20 mA (SCR), Voltage Pulse (SSR), or Relay

- Secondary Control Output Relay Standard on All Models

- Easily Switch Between Auto and Manual Control Modes

- Up to 2 Alarm Relays & 4-20 mA Retransmit Outputs

- Remote Set Value 1-5 V Input Option (4-20 mA with External Resistor)

- Digital Input Set Value Selection

- RS-485 Serial Communications Option

- Modbus® RTU/ASCII Communications

- Mini-USB Port Standard

- FREE Programming and Monitoring Software

- Shallow Depth Case Extends Only 2.5" (63 mm) Behind Panel

- UL & C-UL Recognized Process Control Equipment, Electrical - Component

Front Panel Buttons and Status Indicators

Easy to Read & Operate

The SuperNova PD510 digital controller has two lines with fourdigits each of white & green reverse polarity LCD digits and the PD520 and PD530 have three lines with four-digits each of white, green, & amber reverse polarity LCD digits. All can display commonly used setup parameters defined by the user.Operating Displays & Function Keys

Information-Packed Display

- PV line displays process variable

- SV line displays set value (or selectable for output value on a PD510)

- MV line displays the manipulated value, or the output value as a %. H (heating) and C (cooling) indicated when enabled.

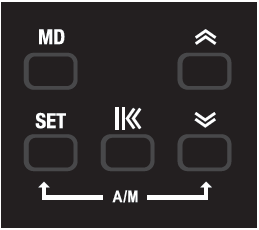

Function Keys

- Hold Shift for two seconds to toggle Run and Stop modes.

- Use SET to change the set value.

- Hold SET and DOWN for three seconds to toggle Automatic and Manual modes.

- Press UP or DOWN to acknowledge a latching alarm.

- Hold SET and Shift for three seconds to Lock/Unlock the unit.

Quick Setup & Programming

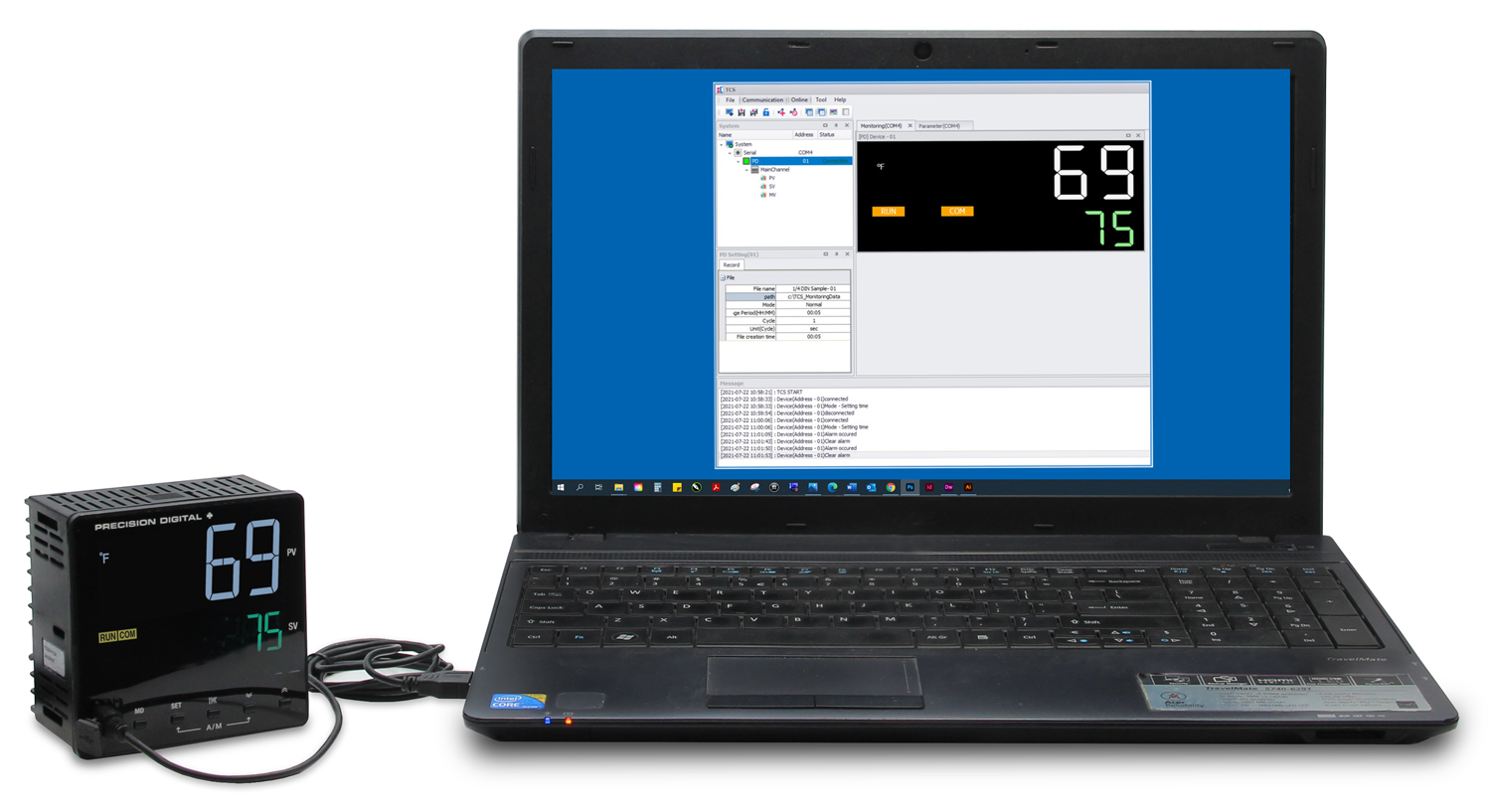

Setup and programming are done through the front panel buttons or using SuperNova TCS software. After power and input signal connections have been completed and verified, apply power to the controller. There are no jumpers to set for the controller input selection.SuperNova TCS Software

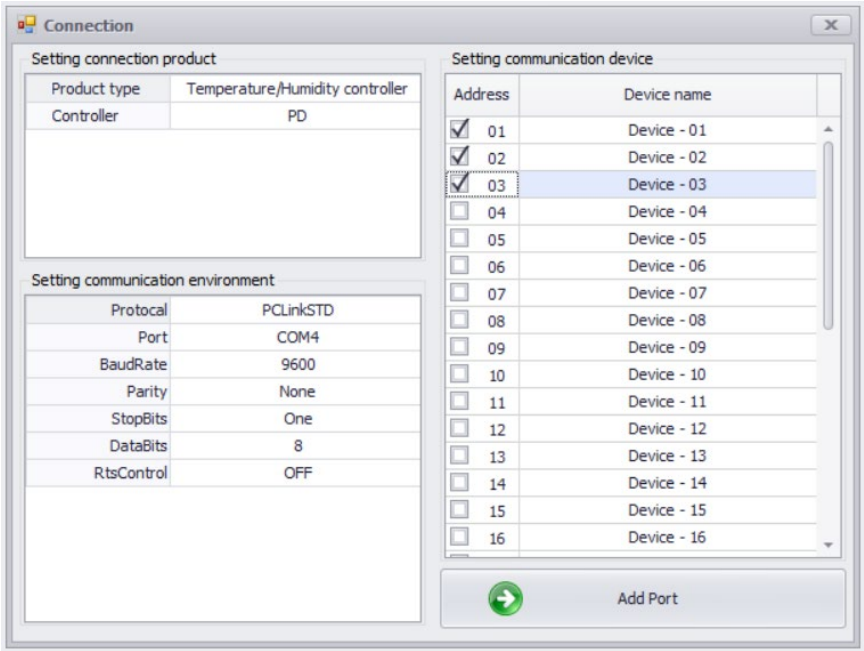

The SuperNova line of controllers includes the FREE SuperNova TCS monitoring and programming software. The easiest and quickest way to connect to the SuperNova TCS software is to use the on-board mini-USB port available on all SuperNova controllers. This software can be used for monitoring, data logging, programming, and troubleshooting SuperNova controllers.

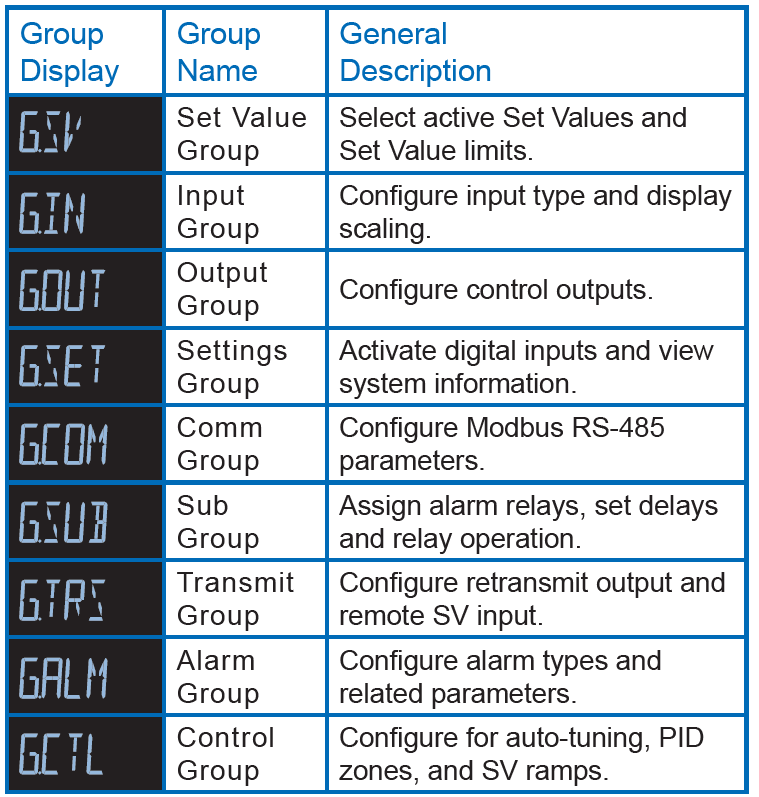

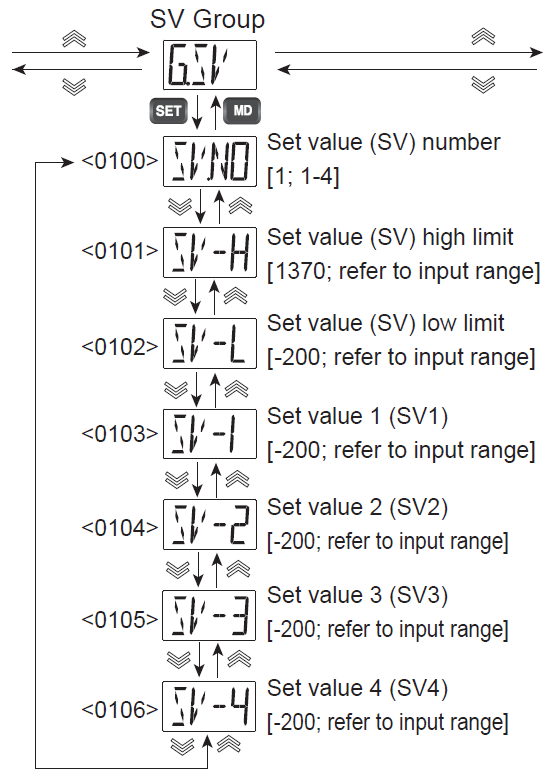

Setup Group Menus

For easy setup parameter navigation, all parameters are grouped by category. To access the group menus, press and hold the Mode (MD) button for one second. Navigate through the group menus using the UP or DOWN arrow buttons. To enter a Group or change a parameter, press SET.

Front Panel Buttons

- Press and hold the Mode (MD) button for one second to enter Programming Mode then press the Down (or Up) arrow button to scroll through the programing groups.

- Hold the Mode (MD) button at any time to exit and return to Run Mode. Changes made to settings prior to pressing SET are not saved.

- To enter a Group or change a parameter, press SET.

- Press the Down (or Up) arrow button to scroll through individual parameters within a Group.

- Press the Mode (MD) button when navigating parameters to return to the group menu.

- Changes to the settings are saved to memory only after pressing SET.

- The display moves to the next menu every time a setting is accepted by pressing SET.

Setup Parameter Lock

To prevent unauthorized changes to key parameters with pushbuttons or software, a user may lock the settings. Two levels of lock exist. Lock setting 1 locks all parameters except LOCK and the G.SV group to allow set value changes. Lock setting 2 locks all parameters except the LOCK parameter. To unlock the controller, an operator must change the LOCK parameter to off (0) with pushbuttons or software.

Easy to Use Menu Structure

Each parameter is located in an associated menu group.

How to Read Parameters and How To

Change Parameter Values

Process & Temperature Inputs

SuperNova Controllers use a single universal input that accepts process and temperature inputs.

Thermocouple: K, J, E, T, R, B, S, L, N, U, W, PLII

RTD: JPT100, PT100

Process: 1-5 V (4-20 mA), 0-5 V, 0-10 V, 0-50 mV, 0-100 mV

External 250 Ω resistor required to read 4-20 mA.

Recommended accessory PDX-RES2.

Versatile Operation

Powerful standard and optional features such as universal inputs, current 4-20 mA (SCR), voltage pulse (SSR), or relay control outputs, two alarm relays, two digital inputs, serial communications, and remote setpoint control make the SuperNova an excellent choice for any process or temperature control application requiring easy to change, visible set points.

Main Control & Secondary Outputs

The main control output can be a 4-20 mA (SCR), voltage pulse (SSR), or relay output. A secondary relay control output is standard, which allow for one or two direction SV control (i.e., heating and cooling).

Mini-USB Port for SuperNova Software

A mini-USB port may be used for a direct PC connection to run the SuperNova software for monitoring, programming, and data logging. This USB port is located behind the panel on the top of the controller for PD510 1/16 DIN models, and on the front behind an IP65 rubber tab on PD520 and PD530 1/8 and 1/4 DIN models.

Easy Auto/Manual Control Mode Switching

Changing between auto and manual control modes is accomplished by holding two buttons that are labelled SET and

Programmable Alarm Relays

All PD500 Series controllers have two SPST alarm relays. These alarm relays can be used for a variety of alarm and control functions and include a number of useful features.

- On/Off Control

- High/Low Alarms

- Set Point Deviation Alarms

- Loop Break Alarm

- Latching or Automatic Reset

- Fail-Safe and Standby Alarms

- Alarm Delays and Wide Deadbands

Analog Retransmit Output

An optional 4-20 mA retransmitting output is available on all sizes of SuperNova Controllers.

This is especially useful when using a temperature input, to provide a 4-20 mA signal to the control room or other equipment.

- 4-20 mA Retransmitting Output

- Retransmit Based on PV, SV, or MV

Auto-Tuning PID

A high accuracy auto-tuning function calculates the PID values for your system with the push of a button, eliminating the need for complex PID calculations and time consuming setup. After several on/off cycles, the PID values will be setup automatically.

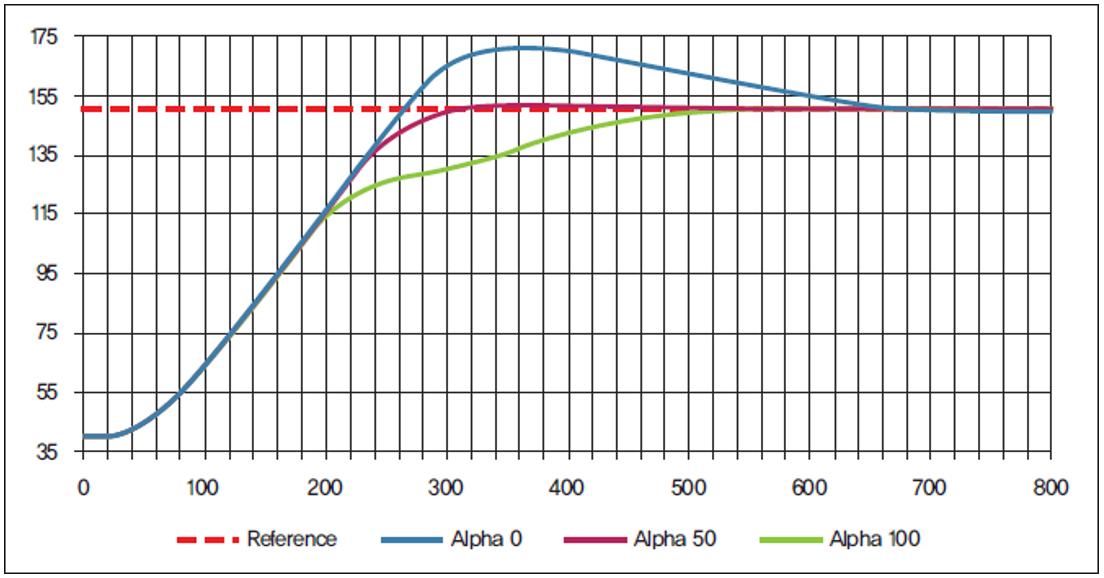

Simple PID Response Adjustment

The Alpha parameter allows for easily adjusting the system response without the need to change P, I, or D values.

The ALPHA parameter is used to adjust the response characteristics to the set value (SV) changes.

If ALPHA is set to 0%, it is the same as the normal PID control response.

If ALPHA is set to 100%, it may take a long time to reach a normal state, but overshoot and undershoot will be minimized.

Set Value Ramp Up/Down

When the ramp functions are used, the set value (SV) changes over time to reach a newly selected set value. When ramp functions are not used, a newly selected SV immediately becomes the active SV.

This is useful to prevent overshoot and protect equipment from rapidly changing output values as set points are changed.

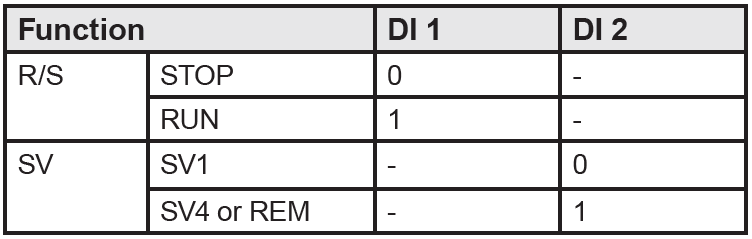

Digital Input Set Point Selection

Two digital inputs can be added as an optional feature. Digital inputs are active with dry contacts or low logic levels. The configuration of the two inputs can select which set point to use (SV1, SV4, or remote) and select run and stop modes.

Normally open switches (external excitation not required) or open collector transistor contacts may be used to operate the digital inputs.

Serial Communications & Adapters

SuperNova controllers with the serial communications option include RS-485 serial communications for Modbus.

The SuperNova Controllers are Modbus server (slave) devices. Process control information can be read from the units, and setting parameters can be read or written to the controllers.

The PDA7485 RS-232 to RS-485 and PDA8485 USB to RS-485 converters are available for use with the SuperNova TCS software or other PC applications. They are especially useful with Modbus communications packages, so multiple controllers on the RS-485 bus may be accessed by computers without RS-485 communications ability.

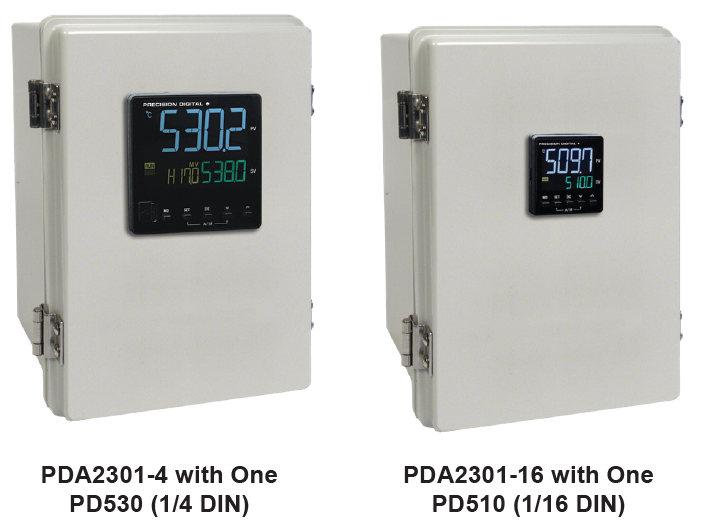

NEMA 4 & 4X Field Enclosures

Precision Digital offers a variety of rugged enclosures

that provide a high degree of protection against harsh

operating environments. These enclosures are available in

thermoplastic, stainless steel (NEMA 4X), and painted steel

(NEMA 4). In addition, Precision Digital offers a Light / Horn

that can be mounted to most of these enclosures to provide

visual and audible indication of alarms. Many enclosures

also have sufficient space to house Precision Digital’s model

PDA1024-01 24 V power supply, signal splitters/isolators/

conditioners, and other devices.

Plastic Enclosures (Externally Mounted)

PDA2300 Series (Covers with Hinge & Latch)

This is Precision Digital’s most economical line of enclosures for the SuperNova. The controller mounts through a hinged cover with a stainless steel latch allowing for easy access to the controller wiring. Enclosures are available for (1-2) PD510, (1-6) PD520, or (1-2) PD530 SuperNovas. The enclosure is large enough to mount the PDA1024-01 DIN rail mounted 24 V transmitter supply.

PDA2800 Series (Covers with screws)

This is Precision Digital’s low cost NEMA 4X plastic line of enclosures for the SuperNova. The controller mounts through the front cover with four screws. Enclosures are available for (1-4) PD510, (1-2) PD520, or (1) PD530 SuperNovas.

Plastic Enclosures (Internally Mounted)

PDA3400 Series (Covers with screws)

The PDA3400 Series enclosures for the SuperNova fully cover the controller. The controller is fully housed inside the enclosure behind a clear plastic cover with four screws. The controller mounts in an internal sub-panel.

Stainless Steel Enclosures

(Externally Mounted)

PDA2600 Series (Covers with Hinge & Latch)

This is Precision Digital’s stainless steel line of enclosures for the SuperNova. The controller mounts through a hinged cover with a SS latch allowing for easy access to controller wiring. Enclosures are available for 1-6 PD520 SuperNovas.

Steel Enclosures (Externally Mounted)

PDA2700 Series (Covers with Hinge & Latch)

This is Precision Digital’s painted steel line of enclosures for the SuperNova. The controller mounts through a hinged cover with a latch allowing for easy access to controller wiring. Enclosures are available for 1-6 PD520 SuperNovas.

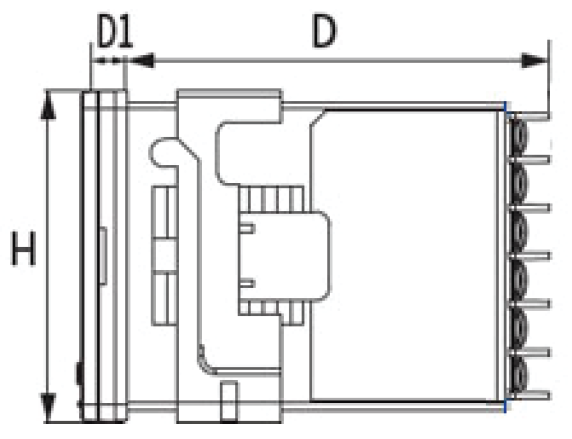

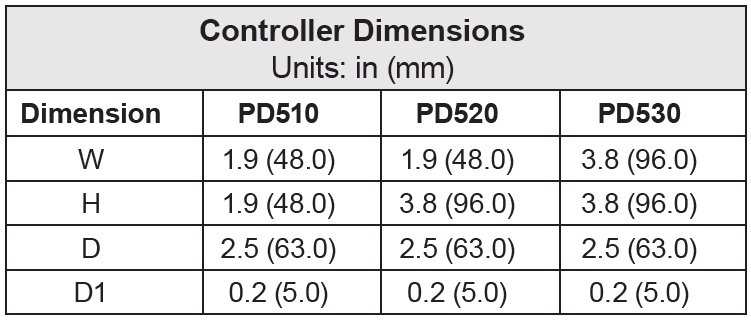

Dimensions

Panel Mounting

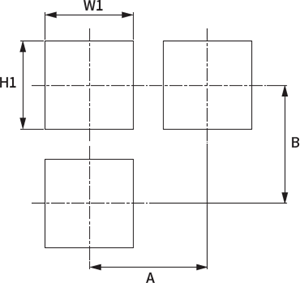

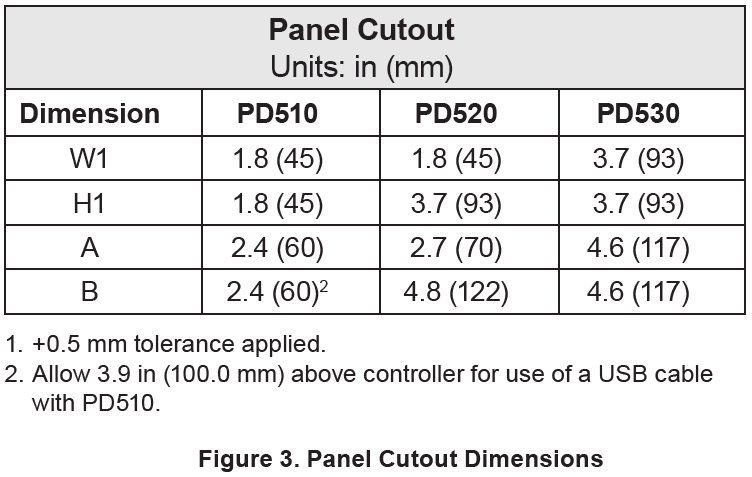

- Prepare the appropriate standard DIN panel cutout. Refer to Figure 3. Panel Cutout Dimensions below for more details.

- Clearance: allow at least 3.5" (88.4 mm) behind the panel for wiring.

- Panel thickness: 0.04" - 0.28"

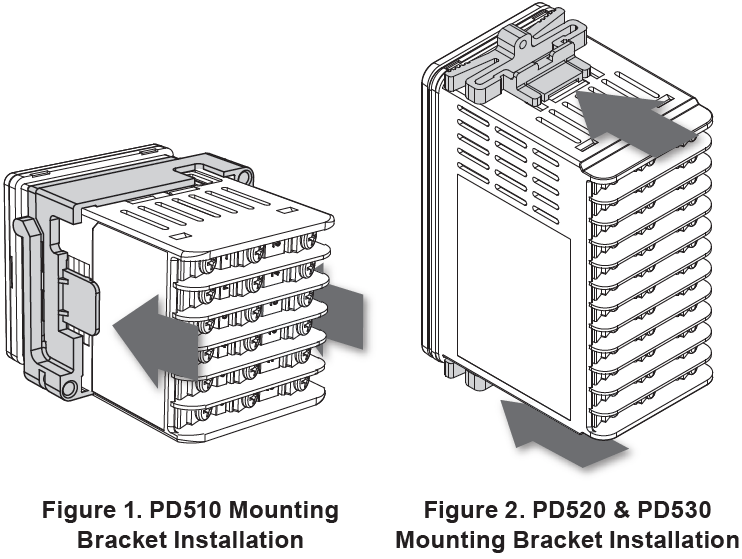

(1.0 mm - 7.0 mm). - Remove the mounting bracket(s) provided with the controller.

- Insert controller into the panel cutout.

- Install mounting bracket(s) and tighten the screws against the panel. To achieve a proper seal, tighten the mounting bracket screws evenly until controller is snug to the panel.

DO NOT OVER TIGHTEN, as the rear of the panel may be damaged. See Figure 1 and Figure 2.

Connections

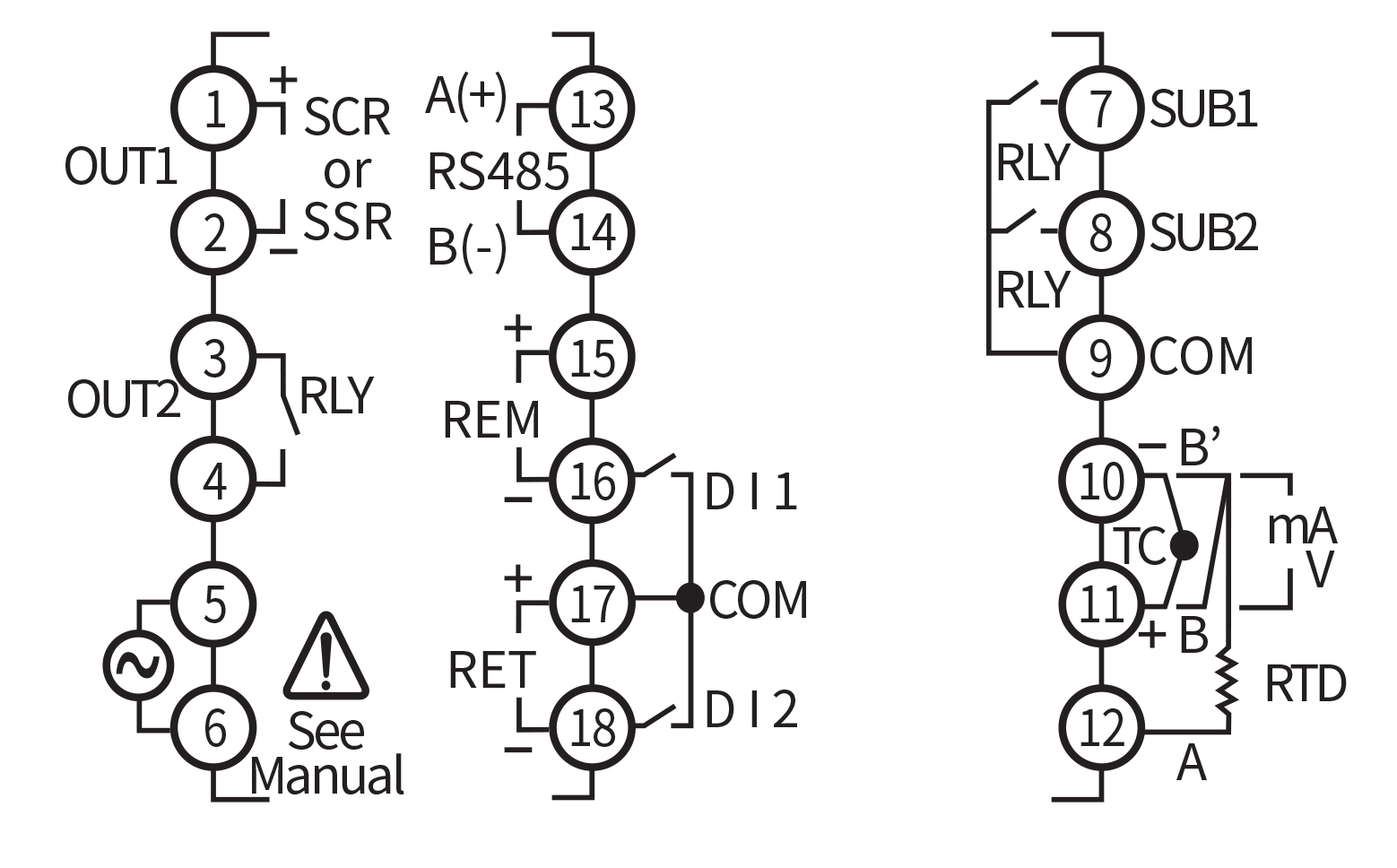

PD510-A or -S (1/16 DIN)

PD510-R (1/16 DIN)

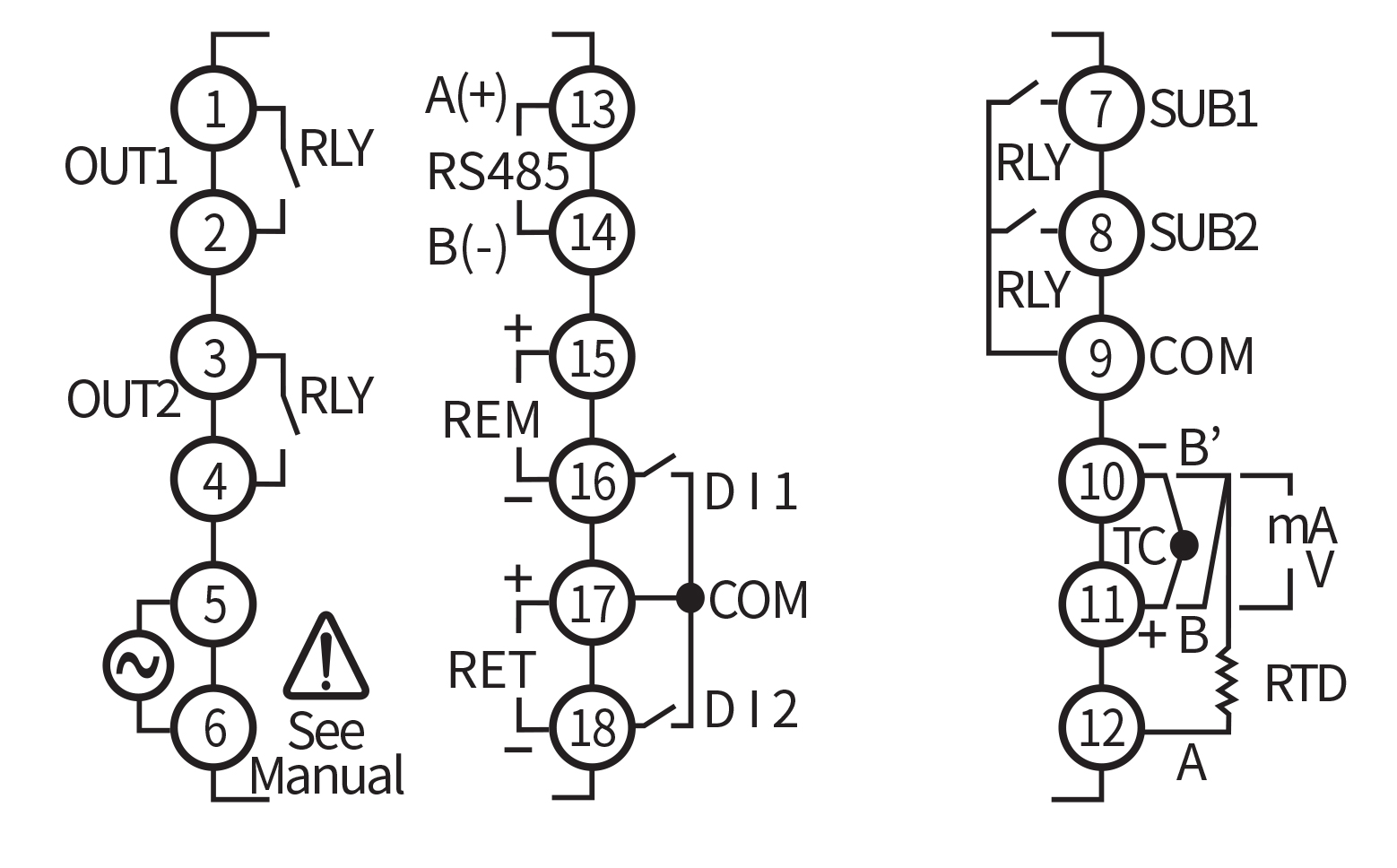

PD520-A or -S (1/8 DIN)

PD520-R (1/8 DIN)

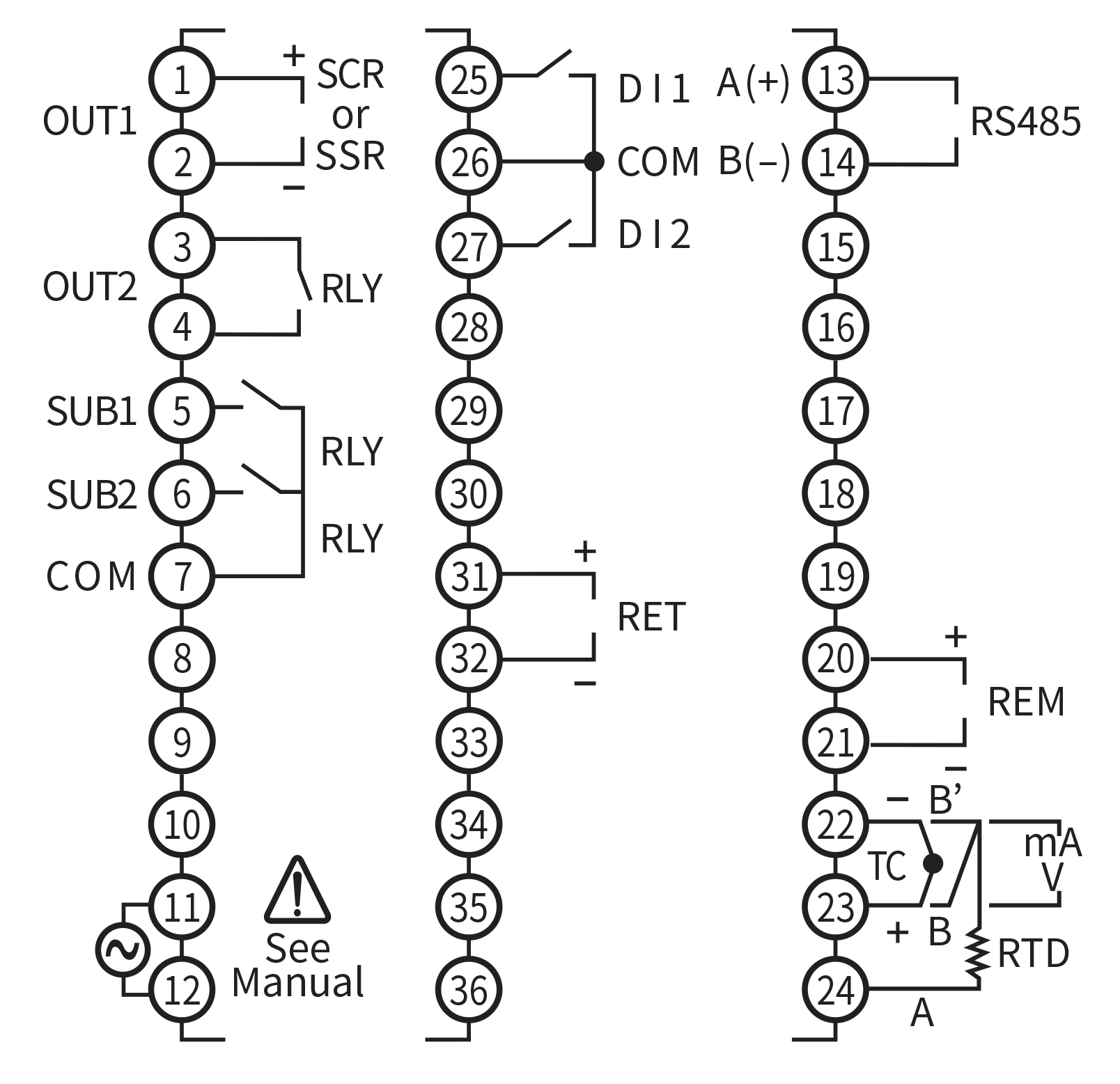

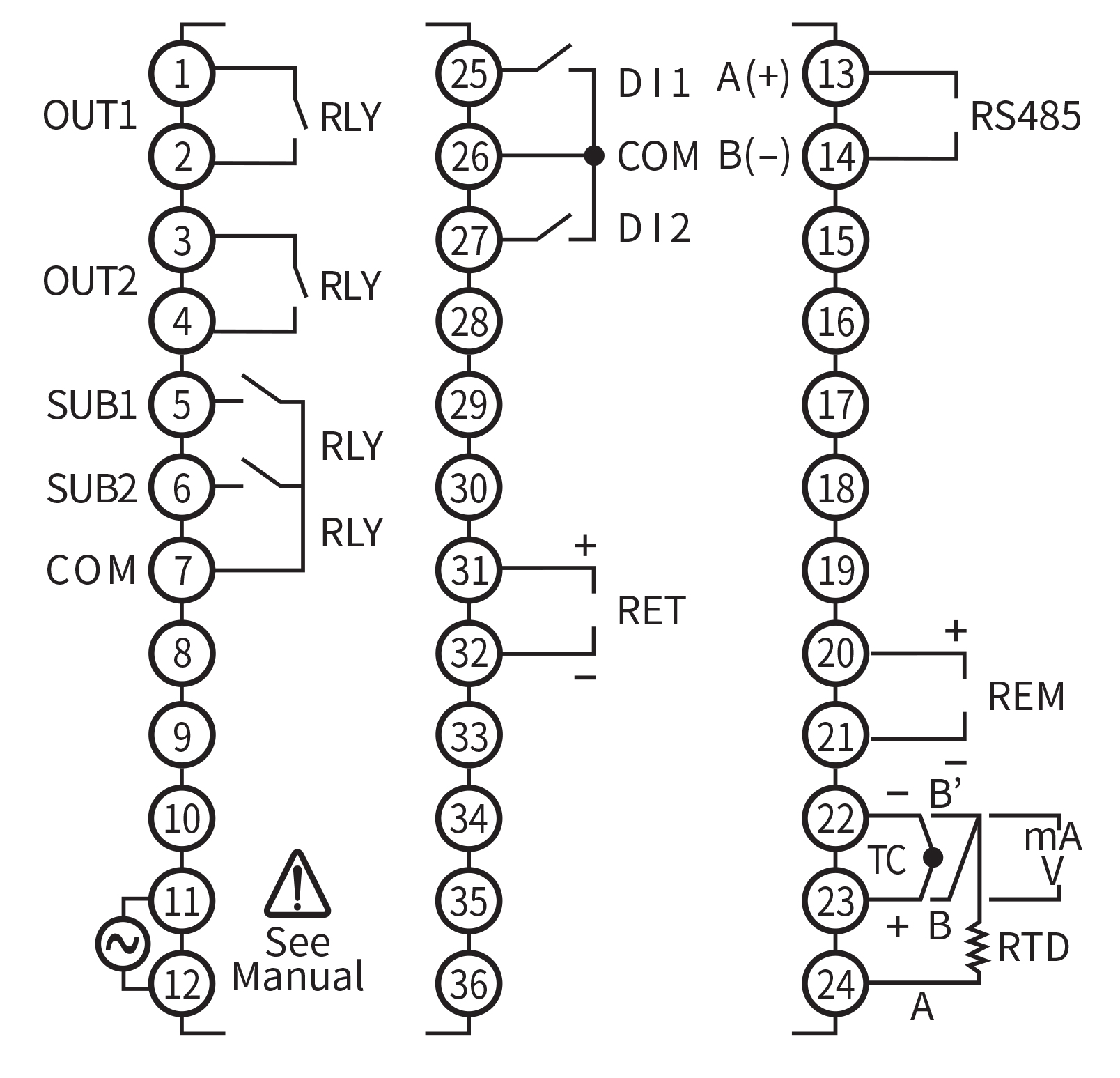

PD530-A or -S (1/4 DIN)

PD530-R (1/4 DIN)

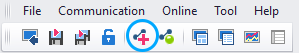

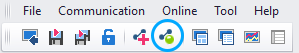

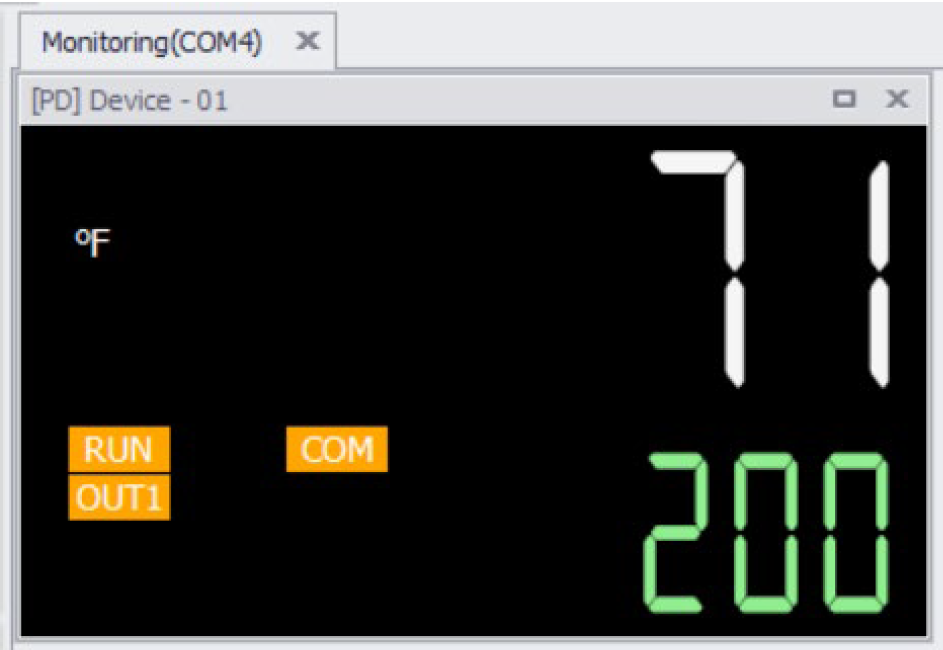

Load Monitoring Data

Load Monitoring Data

Monitoring Data Saving Start

Monitoring Data Saving Start Start Saving All the Monitoring Data

Start Saving All the Monitoring Data /

/  Lock or Unlock

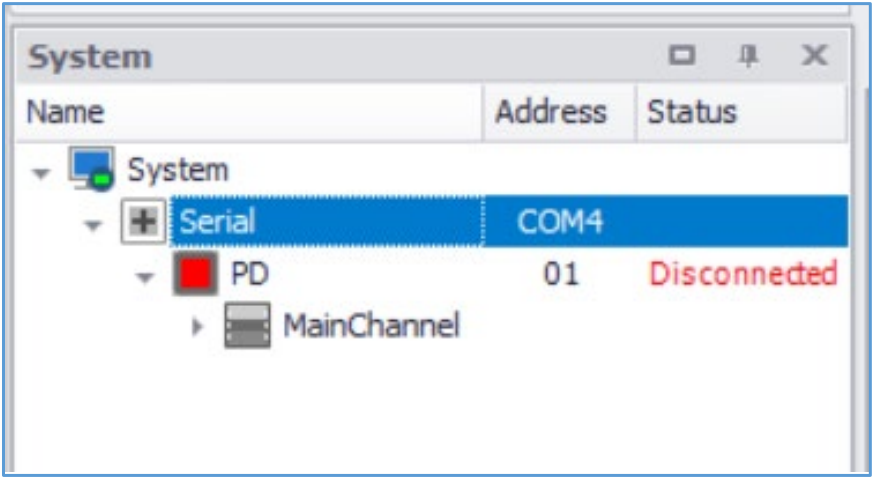

Lock or Unlock Add Serial Communications

Add Serial Communications /

/  Connect or Disconnect

Connect or Disconnect Monitoring

Monitoring

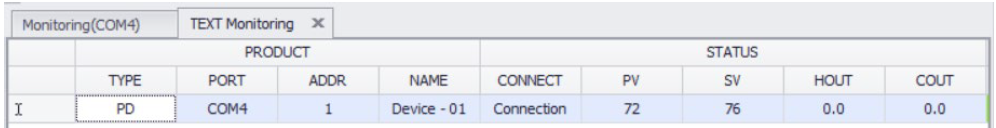

Text Monitoring

Text Monitoring

Multitrend

Multitrend

Parameter

Parameter