Features

- Fully-Approved Explosion-Proof Loop-Powered Process Meter

- 4-20 mA Input

- 1 Volt Drop (4 Volt Drop with Backlight)

- 1.0" (25.4 mm) 3½ Digits LCD Display; -1000 to 1999

- Display Mountable at 0°, 90°, 180°, & 270°

- HART® Protocol Transparent

- Loop-Powered Backlight

- Operating Temperature Range: -40 to 75°C (-40 to 167°F)

- Installation Temperature Range: -55 to 75°C (-67 to 167°F)

- Zero & Span Potentiometer Adjustments for Easy Field Scaling

- Conformal Coated PCBs for Dust and Humidity Protection

- UL Listed as Explosion-Proof / Dust Ignition-Proof / Flame-Proof

- CSA Certified as Explosion-Proof / Dust Ignition-Proof / Flame-Proof

- ATEX and IECEx Certified as Explosion-Proof

- Wide Viewing Angle

- Built-In Flange for Wall or Pipe Mounting

- Explosion-Proof, IP68, NEMA 4X Die-Cast Aluminum & Stainless Steel Enclosures

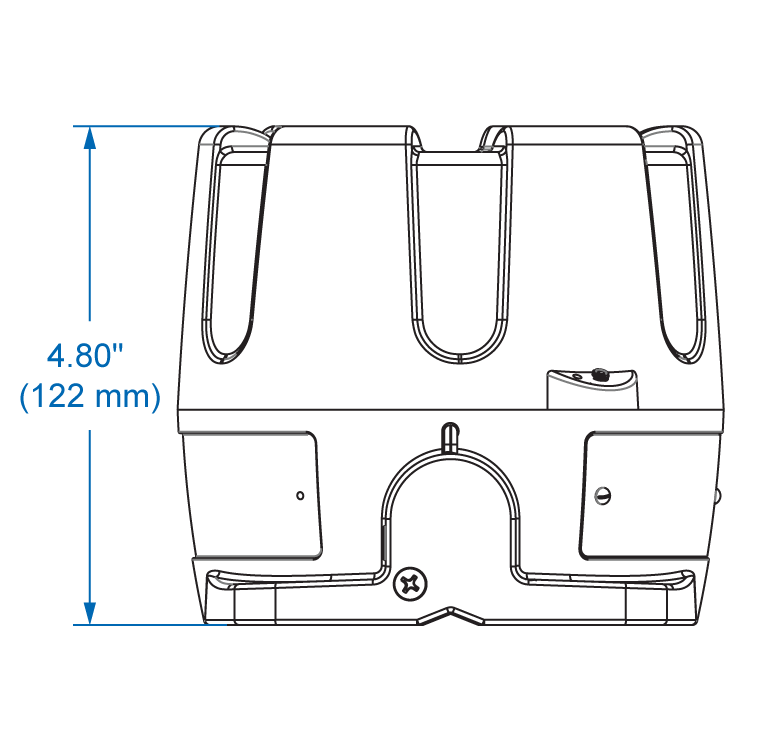

- Two 3/4" NPT or M20 Threaded Conduit Openings

- 2" U-Bolt Kits Available

- Stainless Steel Tag Available

- 3-Year Warranty

Why Use Loop-Powered Meters?

The most basic decision a user wishing to display a 4-20 mA signal on a digital display has to make is: should the meter be powered by line voltage or should it be powered by the 4-20 mA loop?

There are three main benefits of using loop-powered devices:

- No additional power required

- Easy wiring

- Additional digital displays can easily be added in the same loop

The following diagram illustrates how a loop-powered meter is wired. Notice there are only two connections made to the meter.

For more information on loop-powered meters, check out Fundamentals of Loop-Powered Devices and Loop-Powered vs Line-Powered Meters white papers.

Overview

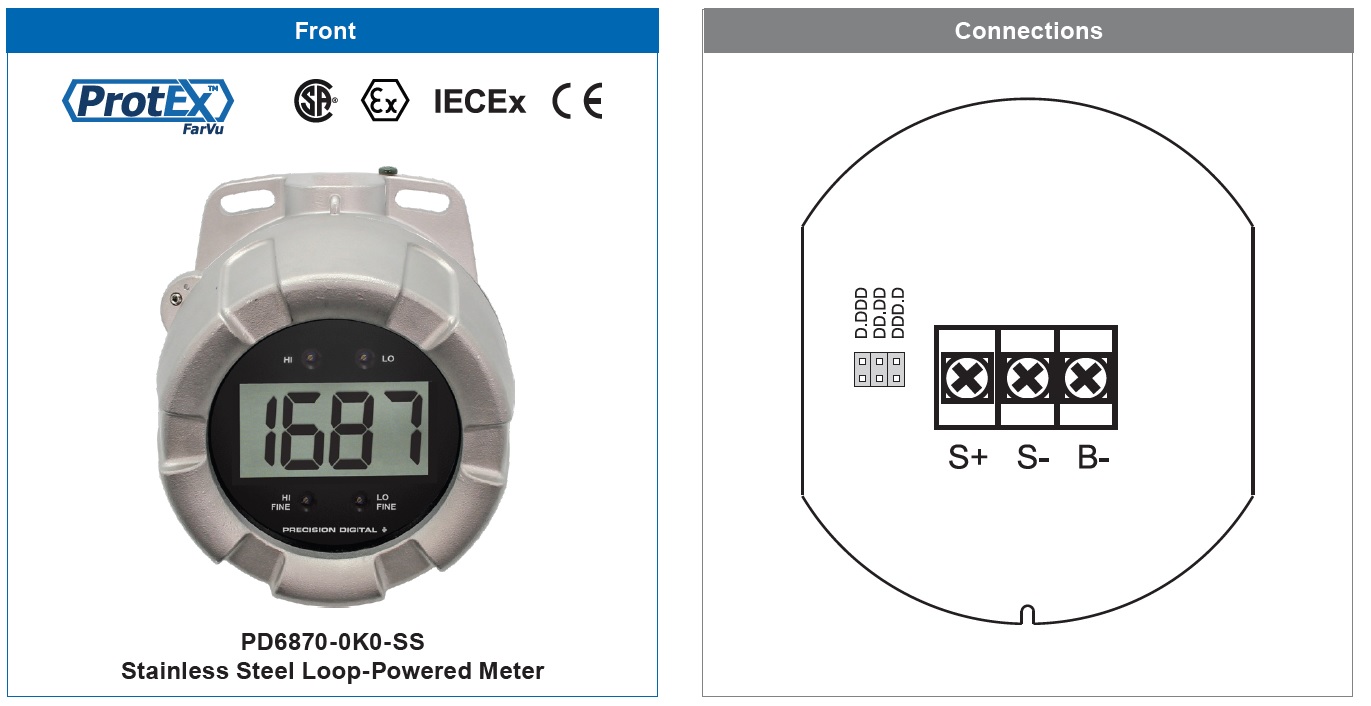

Hazardous Area Loop-Powered Meter

The ProtEX-FarVu PD6870 is a rugged, explosion-proof, loop-powered meter with 1" display digits ideal for demanding applications in hazardous areas or in the harshest environmental conditions.

The ProtEX-FarVu carries all major approvals including:

- UL Listed as Explosion-Proof / Dust Ignition-Proof / Flame-Proof

- CSA Certified as Explosion-Proof / Dust Ignition-Proof / Flame-Proof

- ATEX and IECEx Certified as Explosion-Proof

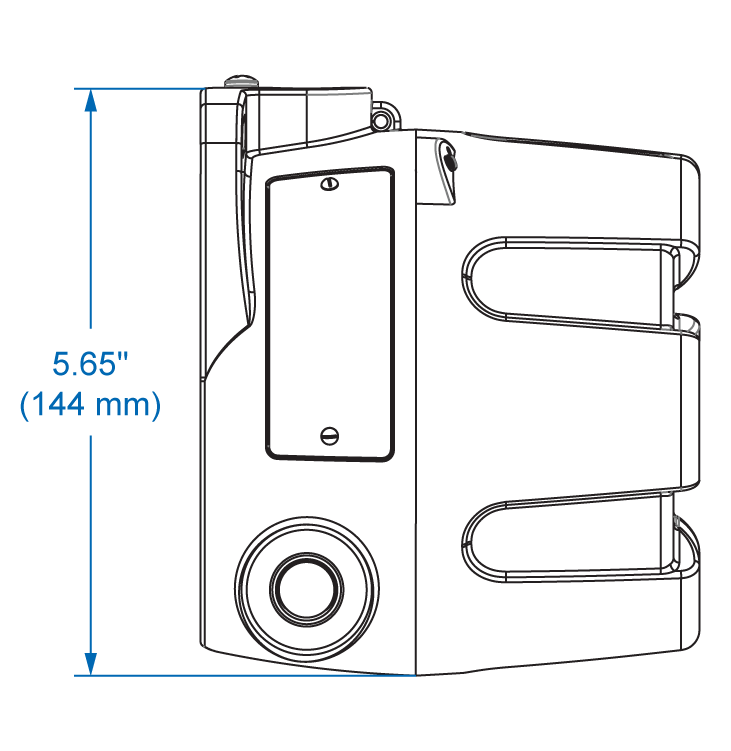

It is available in either an aluminum or stainless steel enclosure with ¾" or M20 connections. It will operate down to -40°C and is approved for installation in areas where the temperature gets as cold as -55°C, however, the display will cease functioning.

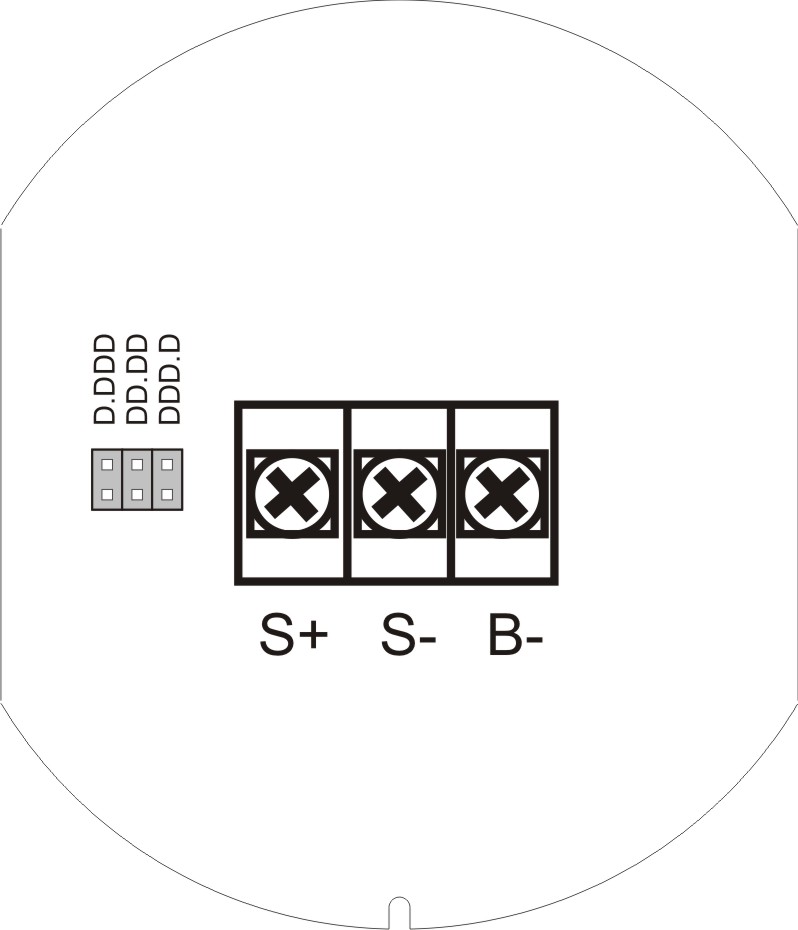

The meter is programmed using four easy to access front-mounted potentiometers.

The numeric display will read from -1000 to 1999 over a 2000 count user adjustable scaling span. The backlight feature lets you see the display under any lighting condition and is powered from the 4-20 mA loop with no additional power supply required. The backlight can be enabled or disabled via alternative wiring of the terminal block.

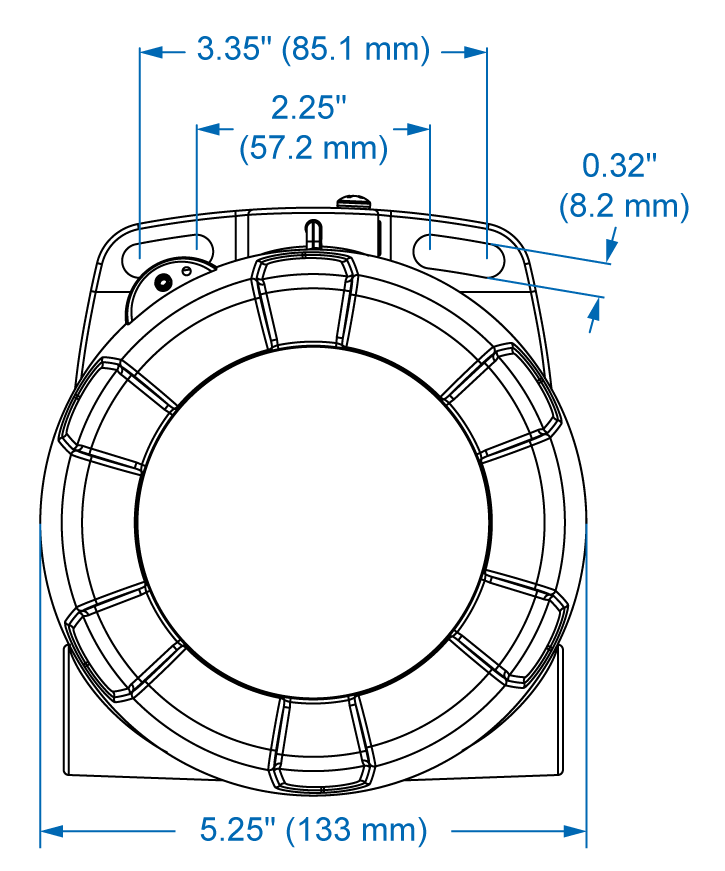

The enclosure is provided with two conduit openings. The built-in mounting flange on the enclosure makes it convenient for pipe or wall mounting.