Features

- Fully Approved Explosion-Proof Analog Input Flow Rate/Totalizers

- 0-20 mA, 4-20 mA, 0-5 V, 1-5 V, and ±10 V Inputs with ±0.03% Accuracy

- Dual-Line 6-Digit Display, 0.6" (15 mm) & 0.46" (12 mm)

- CapTouch Through-Glass Button Programming

- Display Mountable at 0°, 90°, 180°, & 270°

- Isolated 24 VDC @ 25 mA Transmitter Power Supply

- Easy Field Scaling in Engineering Units without Applying an Input

- 4 Relays with Interlocking Capability + Isolated 4-20 mA Output Option

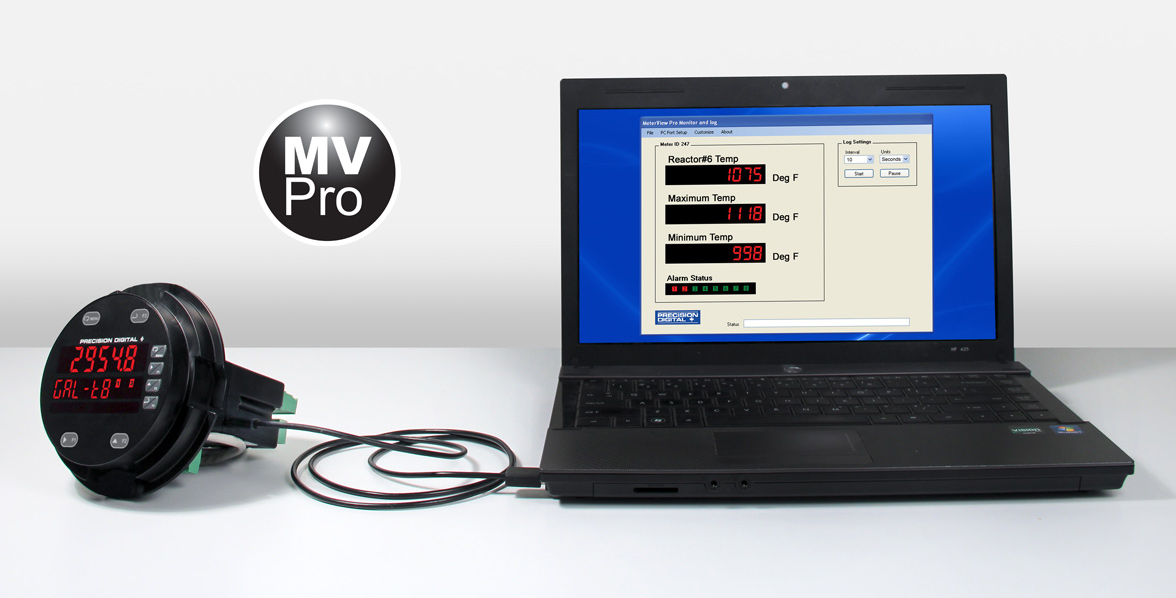

- Free PC-Based, On-Board, MeterView Pro USB Programming Software

- SunBright Display Standard Feature; Great for Outdoor Applications

- Display Rate & Total at the Same Time

- Rate in Units per Second, Minute, Hour, or Day

- Total, Grand Total or Non-Resettable Grand Total

- Front Panel or Remote Total Reset

- Password Protection for Total Reset

- Total Stored in Non-Volatile Memory

- Assign Any Relay for Rate or Total

- 4-20 mA Output for Rate or Total

- Display Open Channel Flow with Programmable Exponent Feature

- 32-Point Linearization & Square Root Extraction

- Operating Temperature Range: -55 to 65°C (-67 to 149°F)

- CSA Certified as Explosion-Proof / Dust-Ignition-Proof / Flame-Proof

- ATEX and IECEx Certified as Dust-Ignition-Proof / Flame-Proof

- Input Power Options: 85-265 VAC / 90-265 VDC or 12-24 VDC / 12-24 VAC

- Programmable Display, Function Keys & Digital Inputs

- Flanges for Wall or Pipe Mounting

- Explosion-Proof Aluminum or Stainless Steel NEMA 4X / IP68 Enclosures

- On-Board RS-485 Serial Communications

- Modbus® RTU Communication Protocol Standard

- Password Protection

- Four 3/4" NPT Threaded Conduit Openings

- Stainless Steel Pipe Mounting Kit and Tag Available

- 3-Year Warranty

Overview

The Only Explosion-Proof Flow Rate/Totalizer You Will Ever Need

The ProtEX-MAX PD8-6200 explosion-proof flow rate/ totalizers are specifically designed for displaying flow rate and total from flowmeters with analog outputs. The meter boasts specifications, features and functionality that make it the only hazardous area flow rate/totalizer you will ever need.

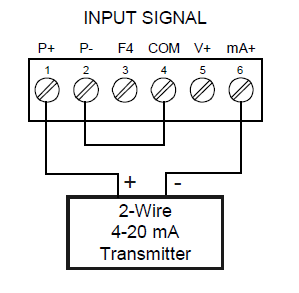

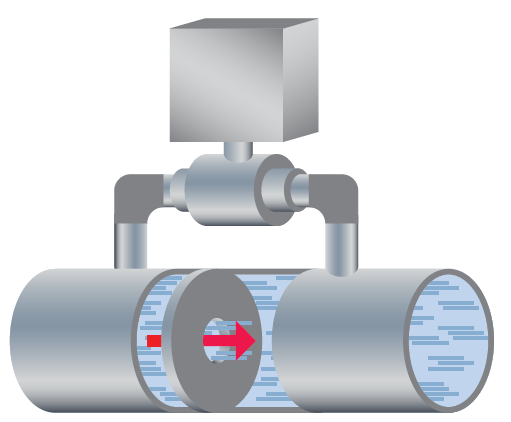

The PD8-6200 has all the same features as our PD6200 1/8 DIN process meter, is certified by CSA as Explosion-Proof / Dust-Ignition-Proof / Flame-Proof and by ATEX and IECEx as Dust-Ignition-Proof / Flame-Proof. Besides being suitable for hazardous areas, the number one feature that makes the PD8-6200 such a useful device is its built in 24 VDC power supply to drive the transmitter as illustrated by the above diagram. This feature not only saves the cost of an external power supply, but also greatly simplifies wiring. In addition, there is a second 24 VDC @ 25 mA power supply provided with the 4 20 mA output option.

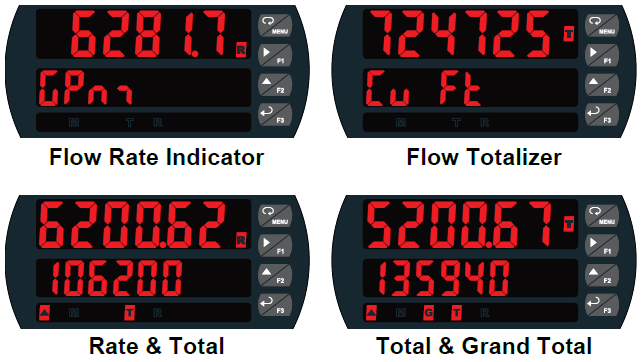

The first thing you notice about the PD8-6200 is its modern looking, rugged, explosion-proof housing with convenient mounting flanges, available in aluminum or stainless steel. Housed inside this enclosure is a dual line, 6 digit display with high intensity LEDs that can be read in direct sunlight. The main display can be programmed to display flow rate, total, or grand total, and the second display can be programmed to display flow rate, total, grand total, engineering units, custom legends, or turned off.

ProtEX-MAX flow rate/totalizers can be programmed for a wide variety of totalizer applications. They can display total, grand total, or non-resettable grand total with a time base of seconds, minutes, hours or days. The user can program a totalizer conversion factor, a non-resettable grand total, password protection, and several total reset methods.

Finally, all these features and capabilities can easily be programmed without removing the cover using CapTouch buttons in a hazardous area or with free MeterView Pro PC based software in a safe area.

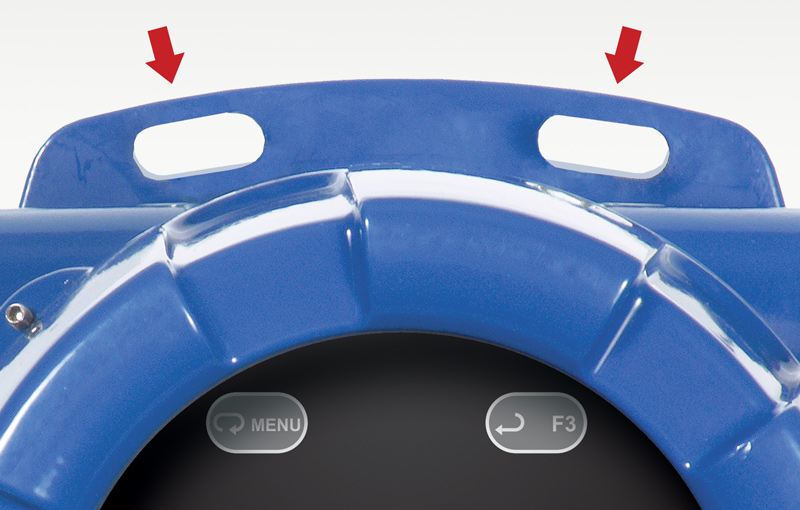

Front

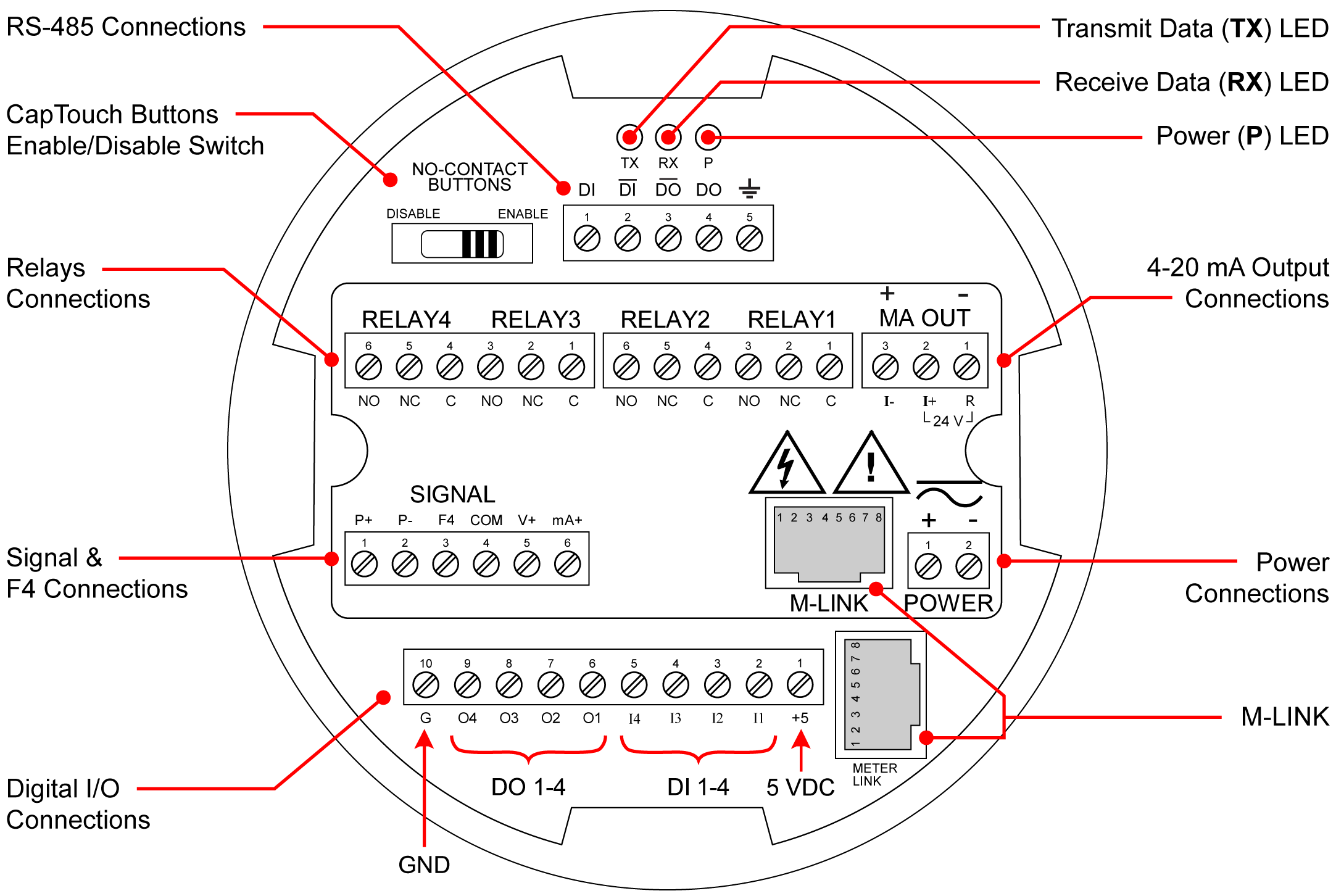

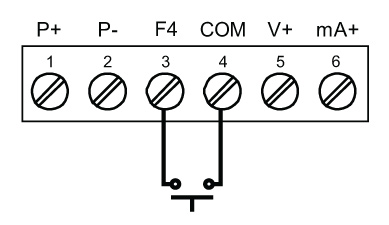

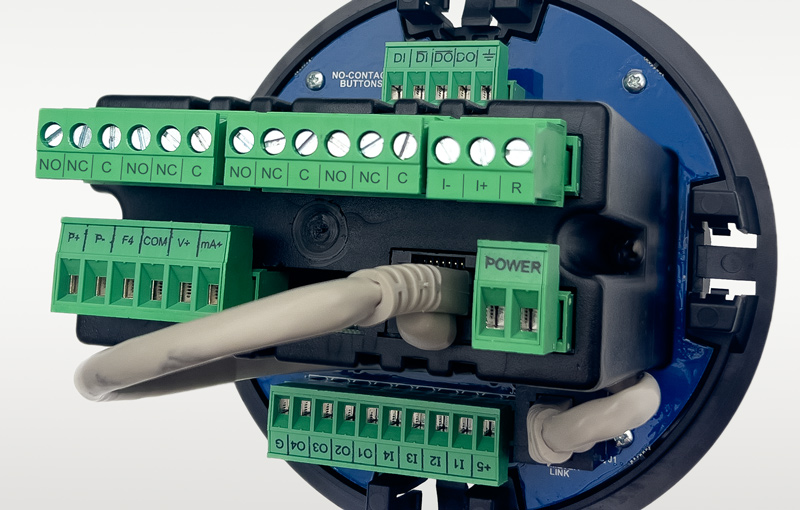

Connections

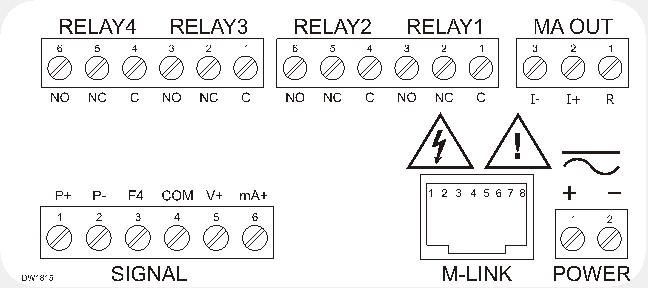

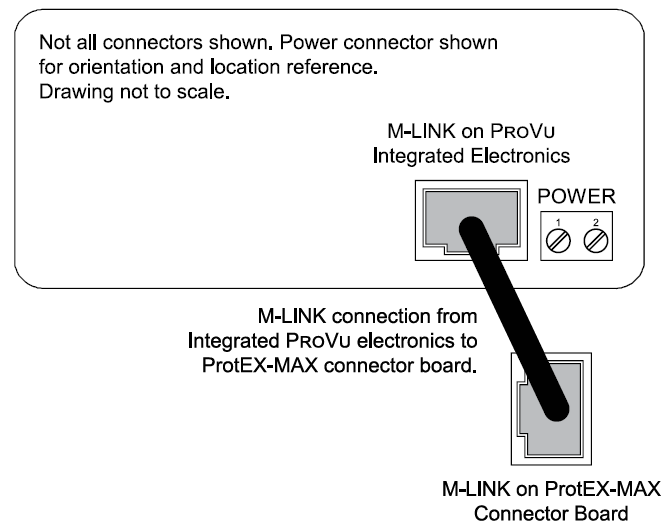

Connections for PD8-6200-6H7 and PD8-6200-7H7

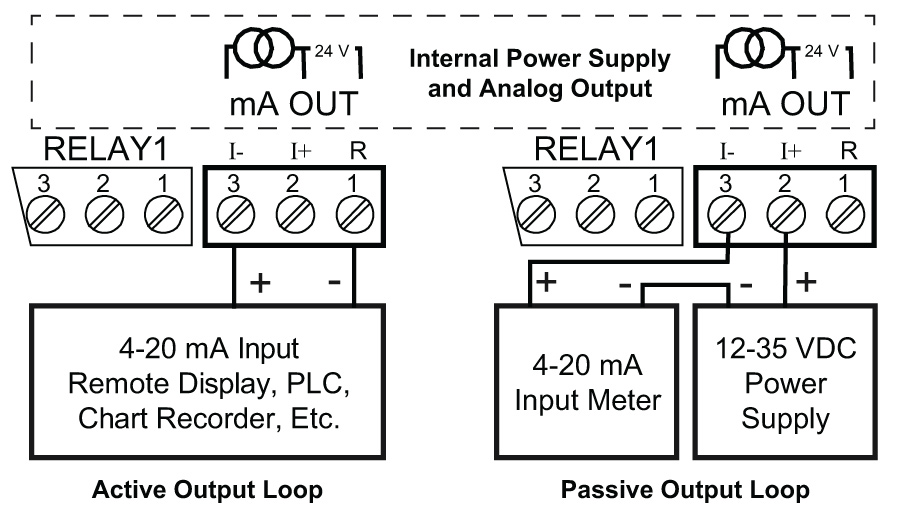

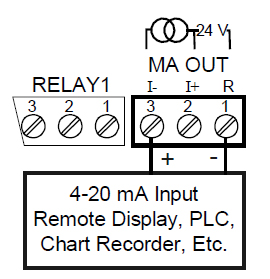

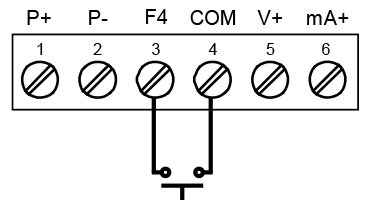

Transmitter Power Supplies

Meter Powers Transmitter

One of the most useful standard features of the PD8-6200 is its built-in isolated, 24 V @ 25 mA power supply to power the transmitter. This feature saves money by eliminating an external power supply and also simplifies wiring by reducing the number of devices in the loop. It can be configured for 5, 10, or 24 V (default) by means of a simple internal jumper. This power supply is even available on meters that are powered from DC power (24 V @ 25 mA). To use an external power supply instead of the internal power supply, simply make connections to different terminals on the ProtEX-MAX.

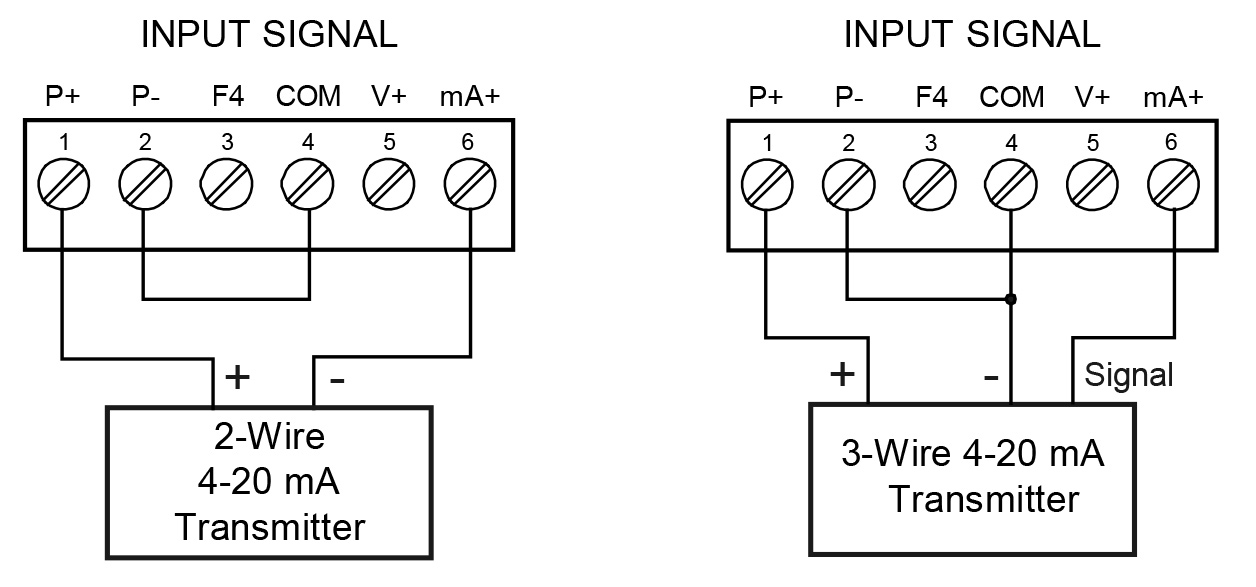

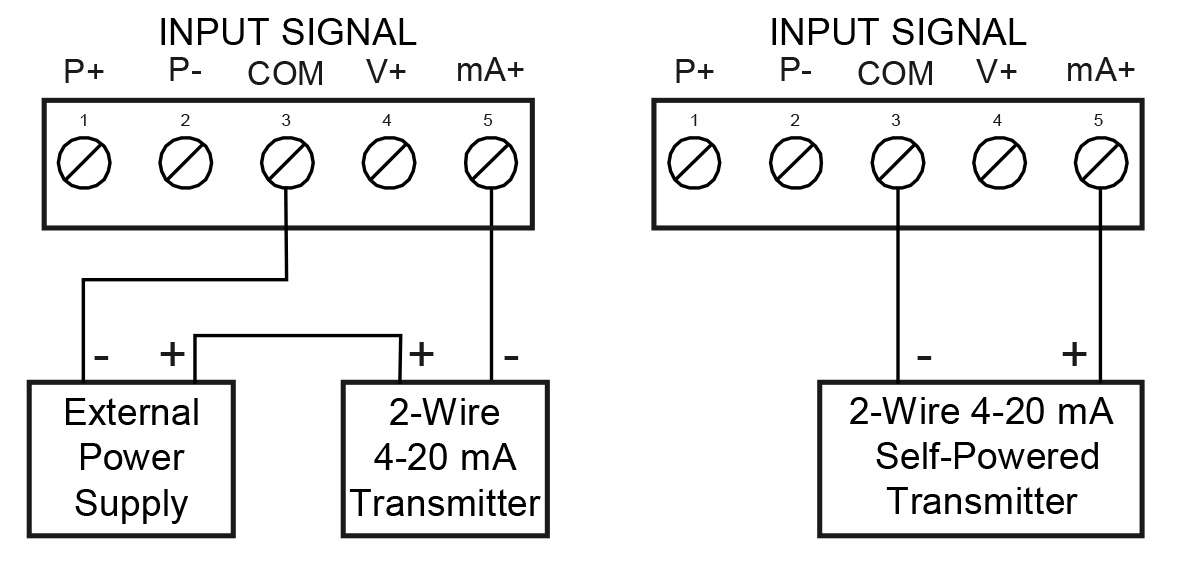

The following diagrams illustrate how to wire the ProtEX-MAX so it will power the transmitter:

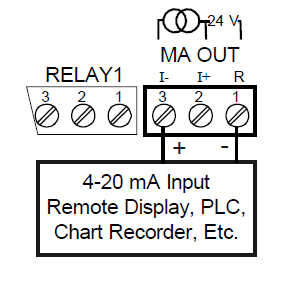

Meter Powers 4-20 mA Output

Not only can the ProtEX-MAX power the 4-20 mA input signal, but an additional power supply of 24 V @ 25 mA is provided with the 4-20 mA output option to power the 4-20 mA output.

Fuse Prevents Current Overload

Another very useful aspect of the ProtEX-MAX is that the current input is protected against current overload by a resettable fuse. The fuse limits the current to a safe level when it detects a fault condition, and automatically resets itself when the fault condition is removed.

Advanced Display Features

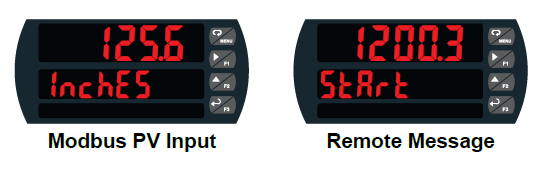

Display Flow Rate, Total or Grand Total

The main display can be programmed to display flow

rate, total, or grand total, and the second display can

be programmed to display flow rate, total, grand total,

engineering units, custom legends, or can be turned off. Both

displays could also display relay set points, or max and min

values. The following images show typical ways these flow

rate/totalizers can be programmed.

Easy to Use

The user-friendly dual-line display makes the ProVu easy to set up & program. No jumpers to set for input selection. All setup & programming is done via the front panel.

Totalizer Overflow Displays Total to 9 Digits

These flow rate/totalizers can display up to nine digits of total flow with the total overflow feature. In the diagram below, the flow totalizer is displaying 532,831,470 by toggling between a display of “oF 532” and “831470”. Notice the (T▲ symbol) is lit up indicating the display is in overflow mode.

Super-Bright Display

The ProtEX-MAX comes standard with a super-bright

display, with LEDs that are visible even in direct sunlight.

The display also has up to eight levels of adjustable intensity

for optimum visibility in any lighting condition.

Rounding Feature for Even Steadier Display

The rounding feature is used to give the user a steadier display with fluctuating signals. It causes the display to round to the nearest value according to the rounding value selected (1, 2, 5, 10, 20, 50, or 100). For example, with a rounding value of 10, and an input of 12346, the display would indicate 12350.

Rate/Totalizer Features

ProtEX-MAX flow rate/totalizers can be programmed for a wide variety of rate and totalizer applications. They can display rate, total, grand total, or a non-resettable grand total with a time base of seconds, minutes, hours or days. The user can program a totalizer conversion factor, a non-resettable grand total, password protection, and several total reset methods. The dual-line display can be programmed to display rate and total at the same time, or a variety of other rate, total and grand total combinations.

Display Rate & Total at Same Time

One of the most useful features of the ProtEX-MAX flow rate/ totalizers is their ability to display both flow rate and total at the same time. Whereas a single-line display would have to toggle between the rate and the total, the ProtEX-MAX’s dual-line display can display them both at the same time.

Totalizer Password Protection

The total and grand total can be password protected so they can be reset only by authorized personnel.

Non-Resettable Grand Total

The user can set up the grand total to be non-resettable by

entering a specific password. Once this is done, the grand

total can never be reset.

Totalizer Conversion Factor

The user can enter a totalizer conversion factor that allows

the meter to display total in different units than the rate. For

instance, a customer could measure flow rate in gallons per

minute and total in hundredths of acre-feet.

Rate in Units Per Sec, Min, Hr, or Day

The user may select a rate time base in units per second,

minute, hour, or day. The time base is the amount of time

over which the rate parameter will totalize. For example, if

the rate was ten (and stayed constant for one minute) and

the time base was in minutes, then the total would increase

by ten every one minute.

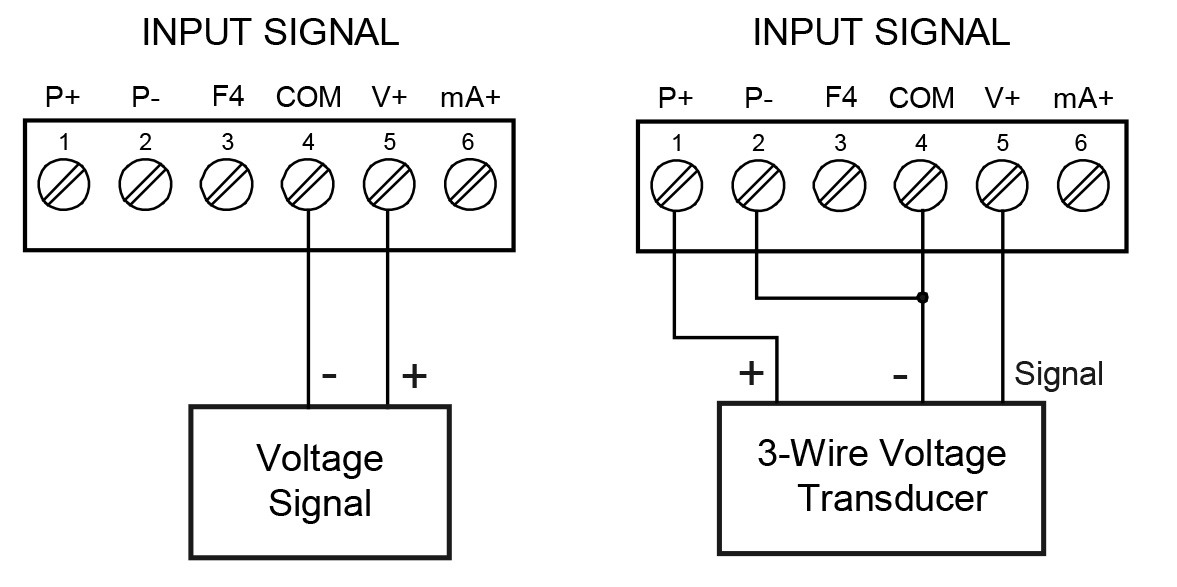

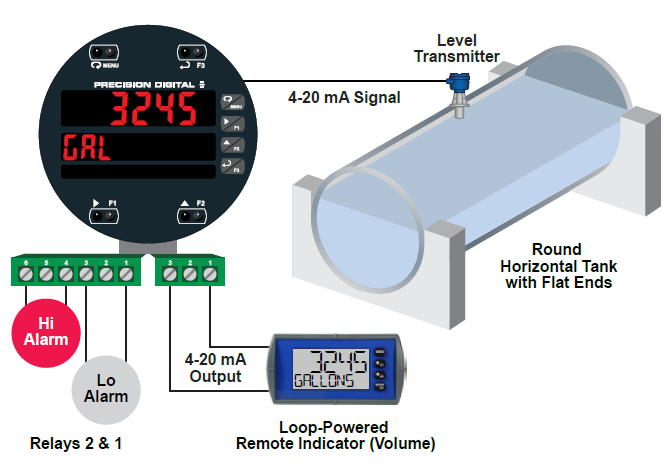

Total & Rate Alarms

The ProtEX-MAX can be equipped with four alarms (relays) that can be set up to activate on the rate or total. In the case of the rate, the relays can be programmed to trip on a high or low rate. In the case of the total, the relays can be programmed to trip when the total reaches a user-defined set point. A variety of reset modes are available and the user can also program time delays and fail-safe operation.

4-20 mA Output for Rate or Total

The 4-20 mA output can be assigned to the rate or total.

Total Stored in Non-Volatile Memory

Total and Grand Total values, and all programmed settings

are stored in non-volatile memory for a minimum of ten years

if power is lost.

Sampling Function (PV Triggered Timed Relay)

The sampling function allows the operator to program a set point for a “sampling” relay. When the process (rate or total) reaches that set point, it will close that relay’s contacts for a preset period of time (0.1 to 5999.9 seconds). An example of its use may be for wastewater sampling. When the wastewater total reaches a preset total interval (i.e. every 10,000 gallons), the relay contacts would close for a preset time, and by some means (light, horn, etc.) alert someone to take a sample, or provide the trigger to automatically take a sample of the wastewater.

The utility of this function can, of course, be expanded beyond sampling and be used whenever a timed relay output closure is required when the rate or a total interval reaches a certain set point.

Total Reset Capabilities

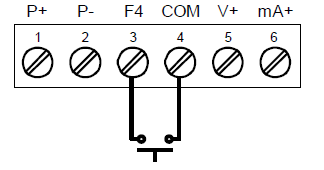

The user may reset the total via a CapTouch button, the F4 terminal at the back of the meter, an external contact closure on the digital inputs, automatically via user selectable preset value and time delay, or through serial communications.

Total Reset via CapTouch Button

The three through-glass CapTouch button function keys can be programmed to reset the total and grand total. This makes it possible for the user to reset either the total or the grand total without opening the enclosure cover and without the need for external devices. Of course, if the total or grand total is password protected, they will not reset when the function key is pressed.

Total Reset via F4 Terminal

The PD8-6200 includes a digital input (referred to as the F4 terminal) located on the back of the electronics module as standard that can be used to reset the total or grand total, among other things. This is the preferred method for externally resetting the total or grand total because it does not interfere with the operation of the CapTouch buttons for programming as described below in the Total Reset via Digital Input section.

Total Reset via Digital Input

In addition to the F4 digital input described above, the PD8-6200 also includes four digital inputs that can be used to reset the total or grand total. However, if a digital input is used to reset the total, or for some other purpose, the corresponding through-glass CapTouch button will function as a programming key.

Total Reset via Preset Value

The total and grand total can be programmed for automatic

or manual reset based on a preset value determined by the

user. In the automatic reset mode, a programmable time

delay is available to reset the total or grand total after the

assigned preset is reached.

Total Reset via Serial Communications

The total and grand total can be reset via serial communications such as a Modbus command.

Quick & Easy Scale & Programing Methods

The ProtEX-MAX can be programmed either via the front panel push buttons or free, PC-based MeterView Pro software. MeterView Pro is resident on the ProtEX-MAX and is accessed by a provided USB cable, so it is by far the easiest way to program the ProtEX-MAX. The ProtEX-MAX can be calibrated either by applying a known signal or scaled by entering a desired value with the front panel buttons or MeterView Pro software. Most customers will use the scaling method because it is simpler and does not require a calibrated signal source. Selecting the input to be current or voltage is done with the front panel buttons or MeterView Pro software. Once programming is completed it can be locked with a password.

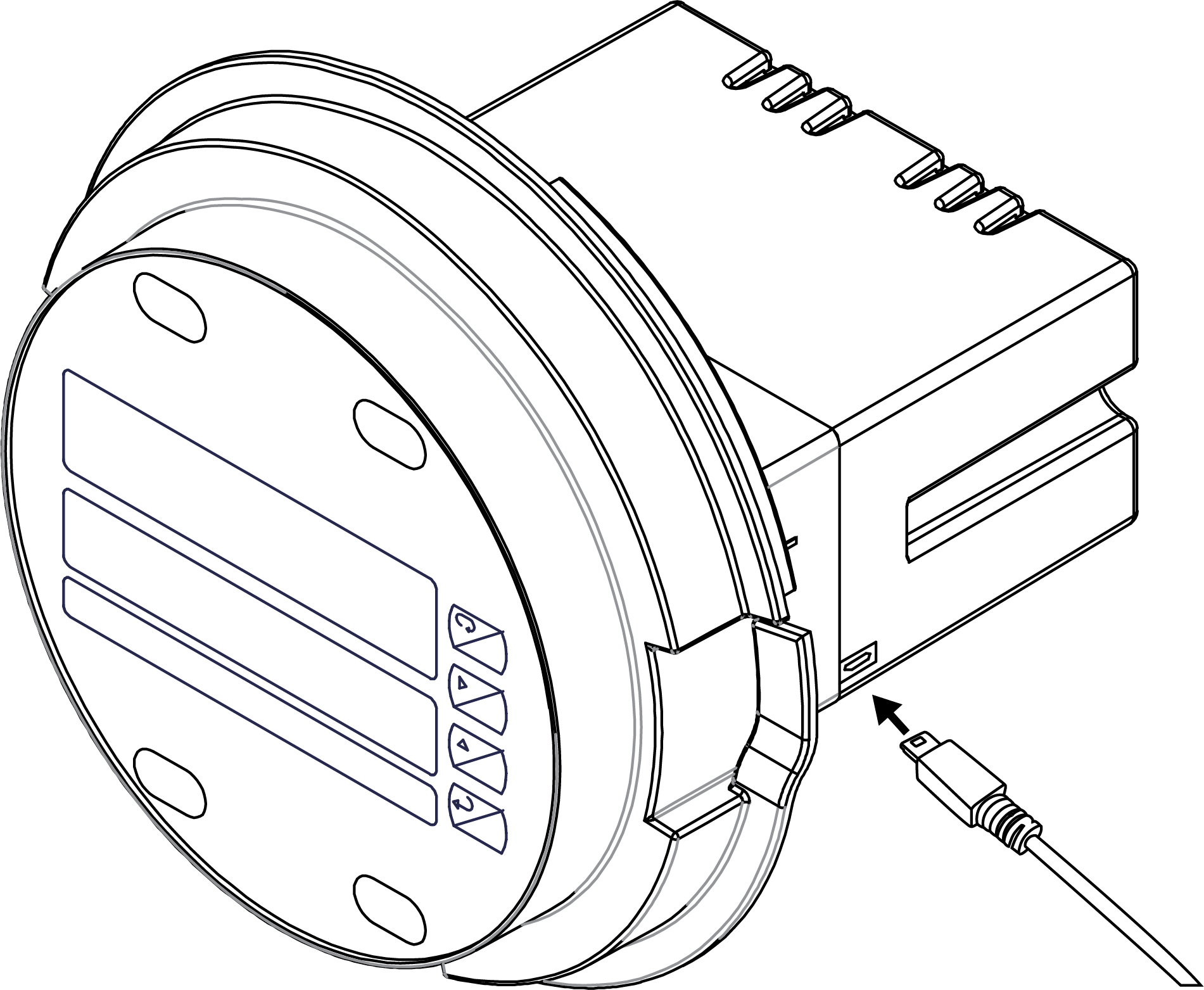

Free PC-Based MeterView Pro USB Programming Software & Cable

The ProtEX-MAX comes preloaded with free MeterView Pro programming software that connects and installs directly to your PC with a standard USB cable, also provided free with each instrument. This eliminates the need to insert CDs, install drivers, or download software from the internet. When you connect your ProtEX-MAX to your PC, MeterView Pro is downloaded to your PC, the software automatically selects the model you are programming, and you’re ready to start programming immediately. Further simplifying the programming process, the ProtEX-MAX can be powered from the USB port, so no need to apply external power while programming your meter. In addition to programming, the software will also allow you to monitor, and datalog a ProtEX-MAX using your PC. You can also generate and save programming files for later use.

CapTouch Through-Glass Buttons

The ProtEX-MAX is equipped with four capacitive sensors that operate as through-glass buttons so that they can be operated without removing the cover (and exposing the electronics) in a hazardous area or harsh environment. CapTouch buttons are designed to protect against false triggering and can be disabled for security by selecting DISABLE on the switch labeled NO-CONTACT BUTTONS located on the connector board.

CapTouch Button Operation

To actuate a button, press one finger to the window directly over the marked button area. When the cover is removed or replaced, the CapTouch buttons can be used after the meter completes a self-calibrating routine. The sensors are disabled when more than one button is pressed, and they will automatically re-enable after a few seconds. When the cover is removed, the four mechanical buttons located on the right of the faceplate are used.

The CapTouch Buttons are configured by default to duplicate the function of the front panel mechanical pushbuttons associated with the integrated meter.

4-20 mA Output & Relays

4-20 mA Analog Output

The isolated analog retransmission signal can be configured to represent the process variable (PV), maximum (peak) value, minimum (valley) value, the value for any of the eight relay set points, or Modbus input. While the output is nominally 4-20 mA, the signal will accurately accommodate under- and over-ranges from 1 to 23 mA.

The 4-20 mA output can be reversed scaled such that 4 mA represents the high value and 20 mA represents the low value. For instance, a 4-20 mA output signal could be generated as the meter went from 100.0 to 0.0.

For applications where the input was linearized by the ProtEX-MAX, the 4-20 mA output will represent that linearized value.

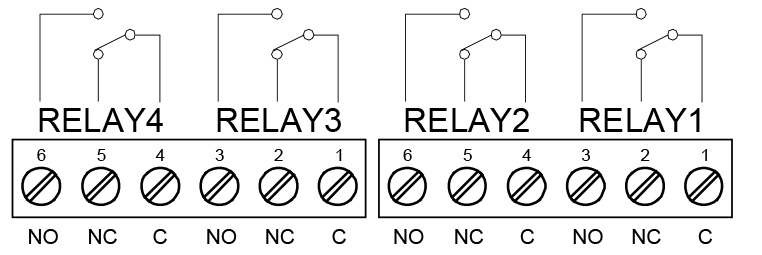

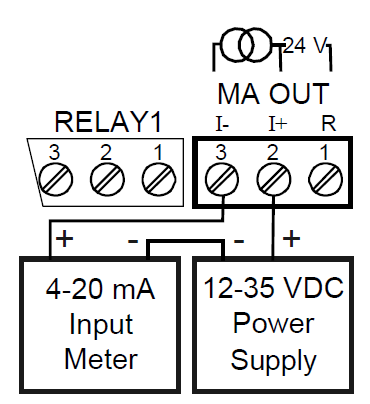

Connections

The ProtEX-MAX can provide 25 mA at 24 VDC to power the 4-20 mA output signal or an external power supply can be used:

4-20 mA Output Powered by PD8-6200

4-20 mA Output Powered by External Power Supply

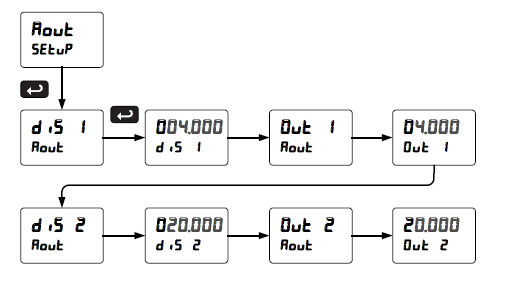

Front Panel Push Button Programming

The 4-20 mA analog output can be scaled to provide a 4-20 mA signal for any display range selected. No equipment is needed to scale the analog output; simply program the display values to the corresponding mA output signal. The Analog Output menu is used to program the 4-20 mA output based on display values.

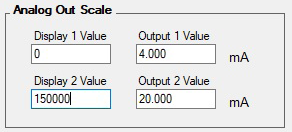

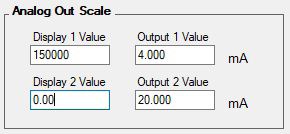

MeterView Pro Software Programming

When a meter is programmed as shown below, the output will be 4.00 mA when the display reads 0 and the output will be 20.00 mA when the display reads 150000.

The meter can be set up for reverse scaling as shown below: the output will be 4.00 mA when the display reads 150000 and the output will be 20.00 mA when the display reads 0.

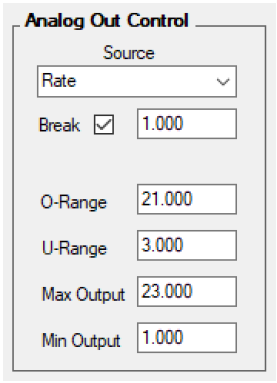

Source: Source for generating the 4-20 mA output (e.g. Rate)

Overrange: Analog output value with display in overrange condition

Underrange: Analog output value with display in underrange condition

Break: Analog output value when loop break is detected

Max: Maximum analog output value allowed regardless of input

Min: Minimum analog output value allowed regardless of input

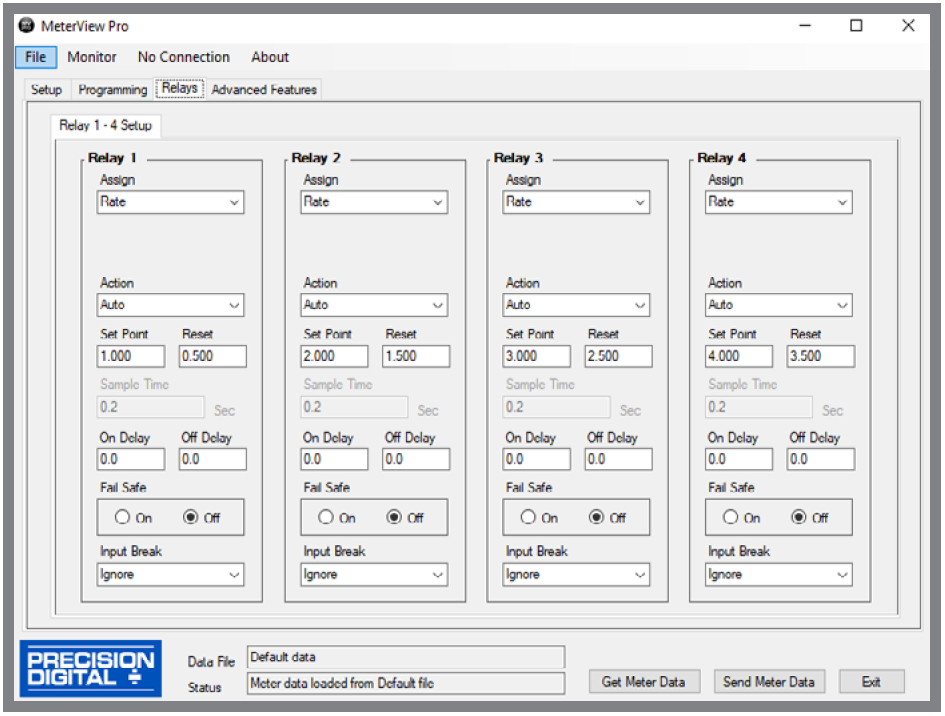

Relays for Hazardous Area Alarm & Control Applications

The 4-20 mA analog output can be scaled to provide a 4-20 mA signal for any display range selected. No equipment is needed to scale the analog output; simply program the display values to the corresponding mA output signal. The Analog Output menu is used to program the 4-20 mA output based on display values.

*Values are intended to show programming choices. They are not intended to represent an actual application.

Setting Set and Reset Points (HI / LO Alarms)

All relays are independent of each other and may be programmed as high or low alarms with user desired set and reset points. Setting a set point above a reset point results in a high alarm and setting a set point below a reset point results in a low alarm. Alarms have 0 – 100% deadband and set and reset points may be set anywhere in the range of the meter.

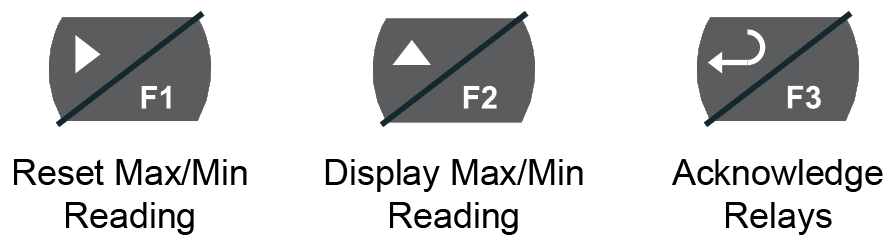

Resetting the Relays (Action in MV Pro)

All relays are independent of each other and may be programmed to reset (Action in MV Pro) in the following ways:

- Automatic: Alarm will reset automatically once the alarm condition has cleared.

- Automatic/Manual: Alarm will reset automatically once the alarm condition has cleared but can also be reset using the F3 front panel button* at any time.

- Latching: Alarm must be reset manually and can be done so at any time. Press the F3 front panel button* at any time to clear the alarm.

- Latching with Reset after Cleared: Alarm must be reset manually and can only be done so after the alarm condition has cleared. Press the F3 front panel button* after the alarm condition has cleared to reset the alarm.

Time Delay (On and Off)

In many applications it is desirable to wait before turning off or on a relay – such as waiting for a process to settle before taking action. Each relay on the ProtEX-MAX can be programmed with independent on and off time delays of 0 to 999.9 seconds to achieve this.

Relays Auto Initialization

When power is applied to the meter, the front panel LEDs and alarm relays will reflect the state of the input to the meter.

Signal Loss or Loop Break Relay Operation

When the meter detects a break in the 4-20 mA loop, the relay will go to one of the following selected actions:

- Turn On (Go to alarm condition)

- Turn Off (Go to non-alarm condition)

- Ignore (Processed as a low signal condition)

User Selectable Fail-Safe Operation

All relays are independent of each other and may be programmed for user selectable fail-safe operation. With the fail-safe feature activated, the relays will transfer to the alarm state on power loss to the meter.

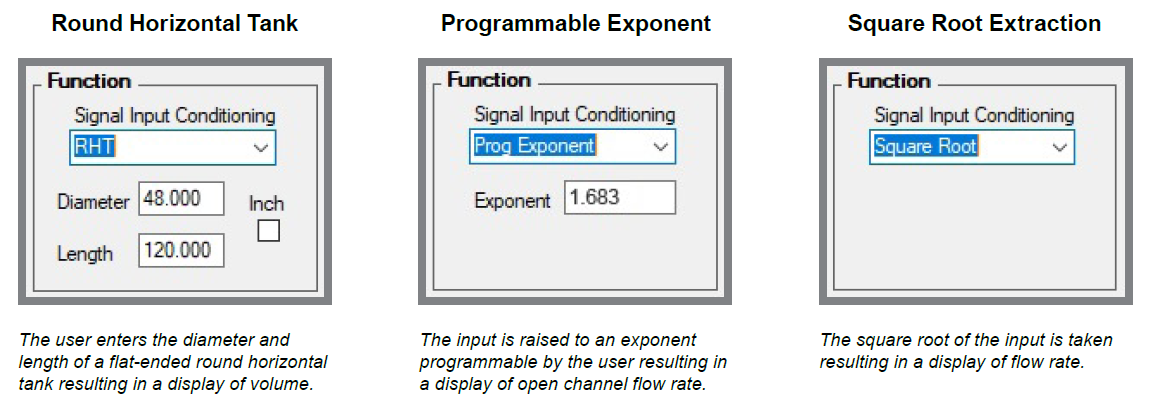

Signal Input Conditioning

There are many applications in the industrial world that can’t be satisfied with simple, two-point linear scaling so the ProtEX-MAX has advanced linearization capabilities to handle applications like round horizontal tank volume measurement, open channel flow, DP flow, and others. And all of these capabilities are easily programmed using MeterView Pro programming software.

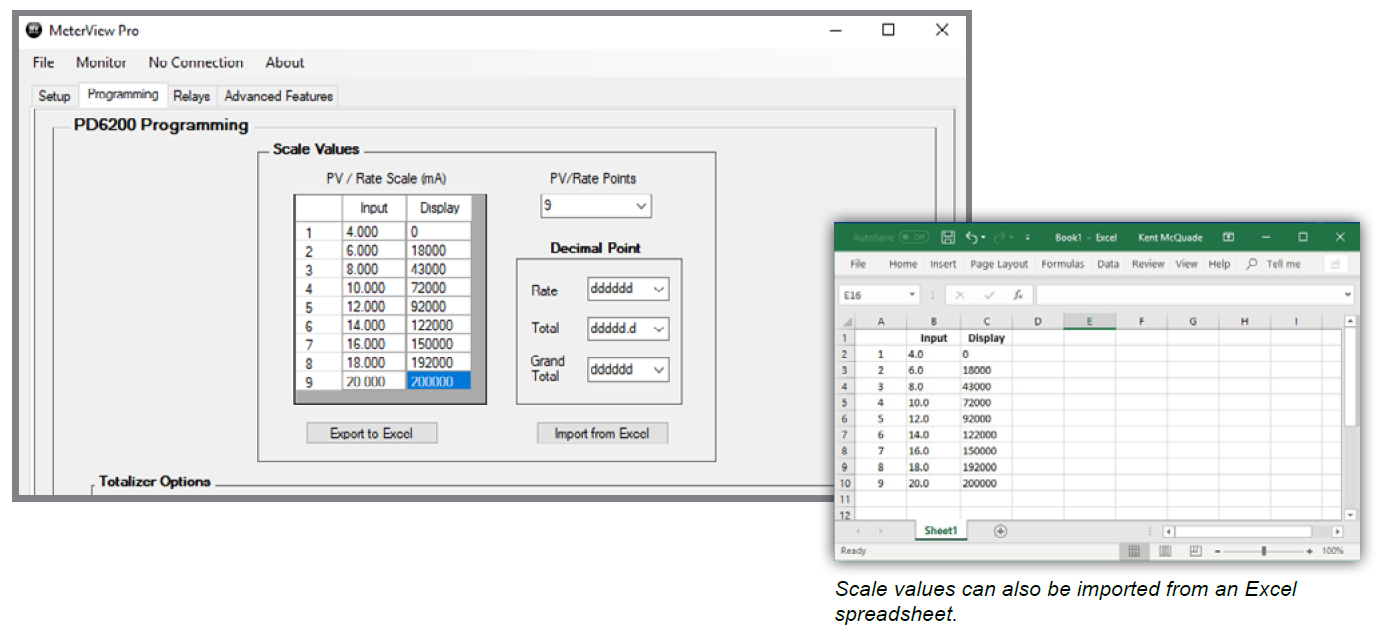

32-Point Linearization

The most common way to linearize a non-linear signal is to break it up into smaller ranges that are more linear than the overall range. The ProtEX-MAX is available with up to 32 points of linearization and if dual scale feature is used, the second PV can have up to eight points of linearization. The linearization data can be imported from an Excel spreadsheet or can be exported from MeterView Pro to an Excel spreadsheet. The following screen shot from MeterView Pro shows PV1 with 9 points of linearization and PV 2 with 5 points of linearization:

Specialized Linearization Functions

In addition to the generic 32- and 8-point linearization functions, the ProtEX-MAX is also available with specialized functions for round horizontal tanks, open channel flow, and DP flow.

Round Horizontal Tank Volume Linearizer

In this application, a level sensor is measuring the height in the round horizontal tank and the ProtEX-MAX is converting that signal to volume using the RHT function. All the user has to do is input the diameter and length of the tank and the meter converts the signal to volume.

DP Flow via Square Root Extraction

In this application, the PD8-6200 is displaying flow rate by extracting the square root from the 4-20 mA signal from a differential pressure transmitter. The user selectable low-flow cutoff feature gives a reading of zero when the flow rate drops below a user selectable value.

Linear 4-20 mA Analog Output

For applications where the input was linearized by the ProtEX-MAX, the 4-20 mA output will represent that linearized value.

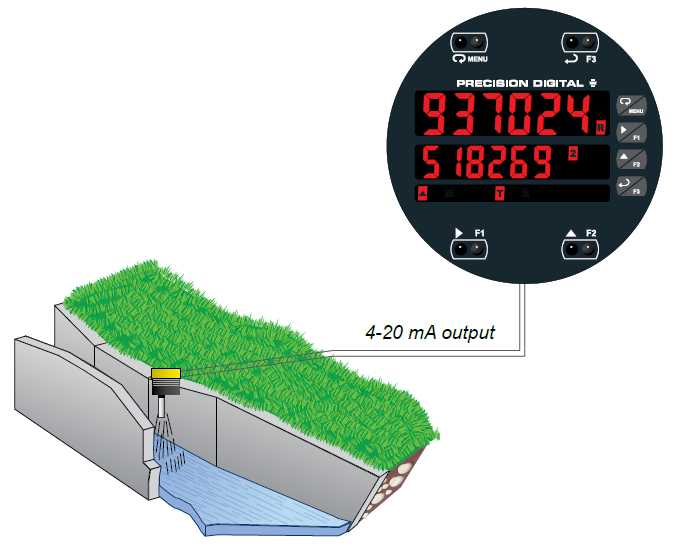

Open Channel Flow Rate Indication

In this application, a level sensor is measuring the height in a weir and the ProtEX-MAX is converting that signal to flow rate using the programmable exponent function. All the user has to do is input the corresponding exponent for their weir and the meter will convert the signal to flow.

The following information is required for programming the PD8-6000 for open channel flow rate:

- The exponent value associated with the flow calculation for the specific weir or flume being used.

- The zero head, or water depth, mA value from the level transmitter.

- The mA value from the transmitter for the maximum head, and the flow rate at that level. The level transmitter is normally programmed to provide 20 mA at the maximum head value and flow rate.

Example:

A 120˚ V-notch weir flow formula for millions of gallons per day is shown below.

MGD=2.798 H2.5

The exponent component is 2.5

The level transmitter has been programmed so that at zero head, when the water level is at the base of the V-notch, the output is 4 mA.

The level transmitter has been programmed so that at the top of the V-notch, at 2.00 ft, the output is 20 mA.1

The coefficient of the flow equation (2.798 in the above example), is not needed for programming the meter; the scaling function of the meter incorporates the coefficient and the head height automatically.

1. Isco Open Channel Flow Measurement Handbook, Sixth Edition, ed. Diane K. Walkowiak, M.A. (Teledyne Isco, Inc., 2006), 168-169.

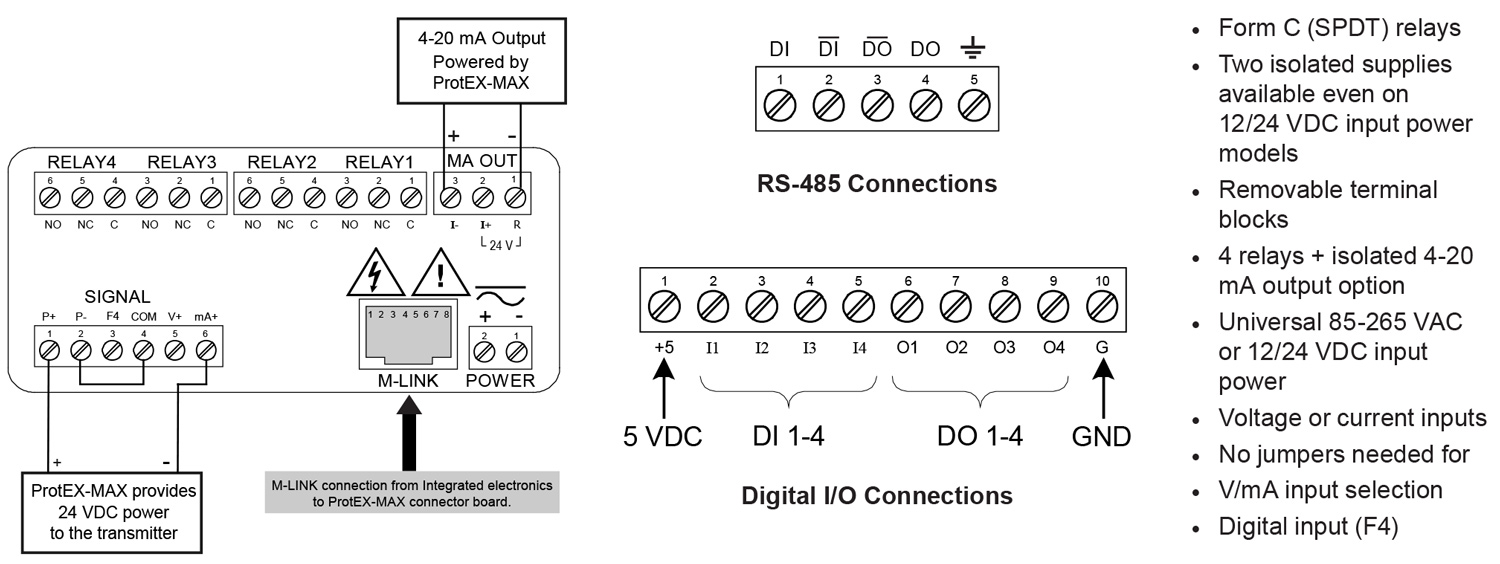

Digital Communications

Modbus® RTU Serial Communications

With onboard RS-485 serial communication, the PD8-6000 can communicate with any Modbus master device using the popular Modbus communications protocol that is included in every ProtEX-MAX. In addition to the typical Modbus capabilities of reading PVs and writing set points, below are some examples of other things that can be done with the meter’s Modbus communications:

- Send a 6-character message to the lower display upon an event

- Convert a digital value to a 4-20 mA signal

- Remote user control (i.e. change set points, acknowledge alarms)

- Input a Modbus digital PV (in place of analog input)

- Remote override of any or all relays and analog outputs

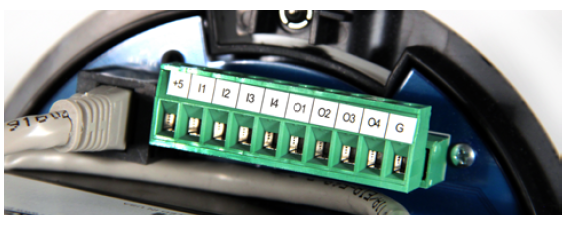

Integrated Digital I/O and Serial Communications

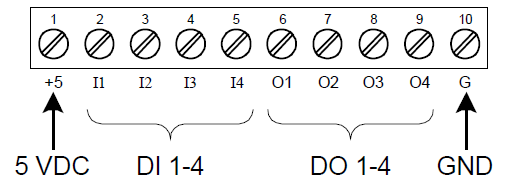

Digital I/O Connections

Four digital inputs and four digital outputs come standard with the ProtEX-MAX. External digital inputs can function similarly to the front panel function keys or digital input F4. They can be configured to trigger certain events (i.e. acknowledge/reset alarms, reset max and/or min values, disable/enable all output relays, and hold current relay states), or provide a direct menu access point. The inputs can be connected to a multi-button control station to provide the user with remote control of the four front panel push buttons.

Digital outputs can be used to remotely monitor the ProtEX-MAX’s alarm relay output states, or the states of a variety of actions and functions executed by the meter.

Note: The onboard digital inputs (1-4) are configured at the factory to function identically to the front panel pushbuttons (Menu, F1, F2, & F3) in order to work with the CapTouch buttons. Changing the programming of the digital inputs will affect the function of the CapTouch buttons.

Serial Communications Connections

ProtEX-MAX meters come with an RS-485 connection for serial communications with other digital devices. The industry standard Modbus® RTU protocol is included with every meter.

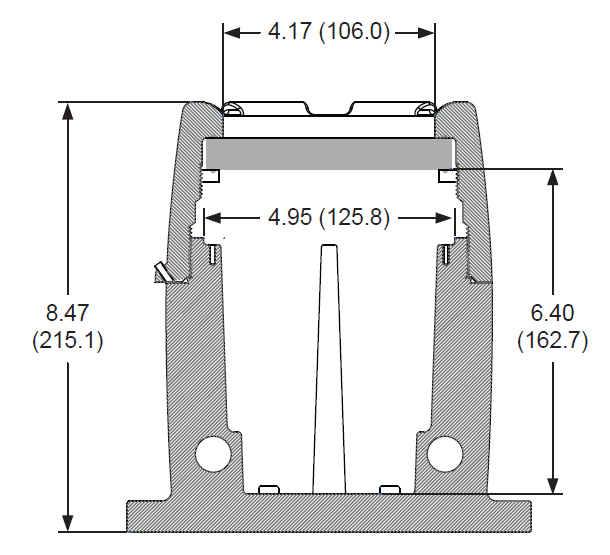

Physical Features

The ProtEX-MAX is designed for ease-of-use in safe and hazardous area applications, and is housed in a rugged NEMA 4X explosion-proof enclosure, available in either aluminum or stainless steel. The PD8-6000 can operate over a wide temperature range (-55 to 65°C / -67 to 149°F), includes removable screw terminal connectors, can have up to four relays and a 4-20 mA output, and features through‑glass buttons for easy meter operation without the need to remove the cover. All of these features are backed by a 3-year warranty.

Super-Bright LED Display

The ProtEX-MAX features a dual-line 6-digit display with super-bright LEDs, our brightest ever. These allow the display to be read in any lighting condition, even in direct sunlight.

CapTouch Through-Glass Buttons

The ProtEX-MAX is equipped with four capacitive sensors that operate as through-glass buttons so that it can be programmed and operated without removing the cover (and exposing the electronics) in a hazardous area. These buttons can be disabled for security by selecting the DISABLE setting on the NO-CONTACT BUTTONS switch located on the back of the electronics module, inside the enclosure.

Rugged, Heavy-Duty Enclosure

The ProtEX-MAX is housed in a rugged NEMA 4X, 7, & 9, IP68 aluminum or stainless steel enclosure, designed to withstand harsh environments in safe and hazardous areas.

Wide Viewing Angle

Customers can’t always look at the display from straight on, so the window and display module have been optimized to provide a wide viewing angle of approximately ± 40°; nearly twice that of the competition.

Built-In Mounting Flanges

The ProtEX-MAX is equipped with two slotted flanges for wall mounting or NPS 1½" to 2½" or DN 40 to 65 mm pipe mounting.

Flexible Mounting & Wiring

The ProtEX-MAX features four ¾" NPT threaded conduit openings so that wiring can be routed to the most convenient conduit connection(s).

Rotatable Display

The ProtEX-MAX rotatable display, along with four available conduit connections, provide for numerous installation options. The display can be rotated in 90° increments. Rotate it 90° for horizontal mounting.

Stainless Steel Tags

PDA-SSTAG is a laser etched stainless steel tag accessory for any of your Precision Digital meters. The tag features custom text for equipment identification, instruction, or whatever else is needed in your facility. Each tag comes with a stainless steel wire and lead seal for easy mounting wherever you need it.

Removable Screw Terminal Connectors

Industrial applications require screw terminal connections for easy field wiring and the ProtEX-MAX goes one step further in convenience by making them removable also.

Wide Operating Temperature Range

The ProtEX-MAX can operate from -55 to 65°C (-67 to 149°F) meaning it can be installed in a wide variety of indoor and outdoor industrial applications.

Operational Features

Function Keys, F4 Terminal, Digital Inputs

There are three ways the user can interact with the ProtEX-MAX to perform a variety of useful functions:

1. Three Front Panel Function Keys

The default settings for the function keys are:

One of the most common uses for a front panel function key

is to reset the total or grand total.

2. CapTouch Through-Glass Buttons

The ProtEX-MAX is equipped with four capacitive sensors that operate as through-glass buttons so that it can be programmed and operated without removing the cover (and exposing the electronics) in a hazardous area. The CapTouch buttons are configured by default to duplicate the function of the front panel mechanical pushbuttons associated with the integrated meter.

3. Built-in Digital Inputs/Outputs

The ProtEX-MAX comes with five digital inputs and four digital outputs. The digital inputs can be used to reset the total and grand total, operate with the tare, reset tare, or interlock relays feature, force relays on from a signal from a PLC or relay on other equipment, and much more. The digital inputs can also be connected to an appropriately approved control station to provide remote control of the programming / operation buttons. The digital outputs can be used to send signals to PLCs and other devices.

4 Digital Inputs & 4 Digital Outputs

F4 Terminal for Digital Input