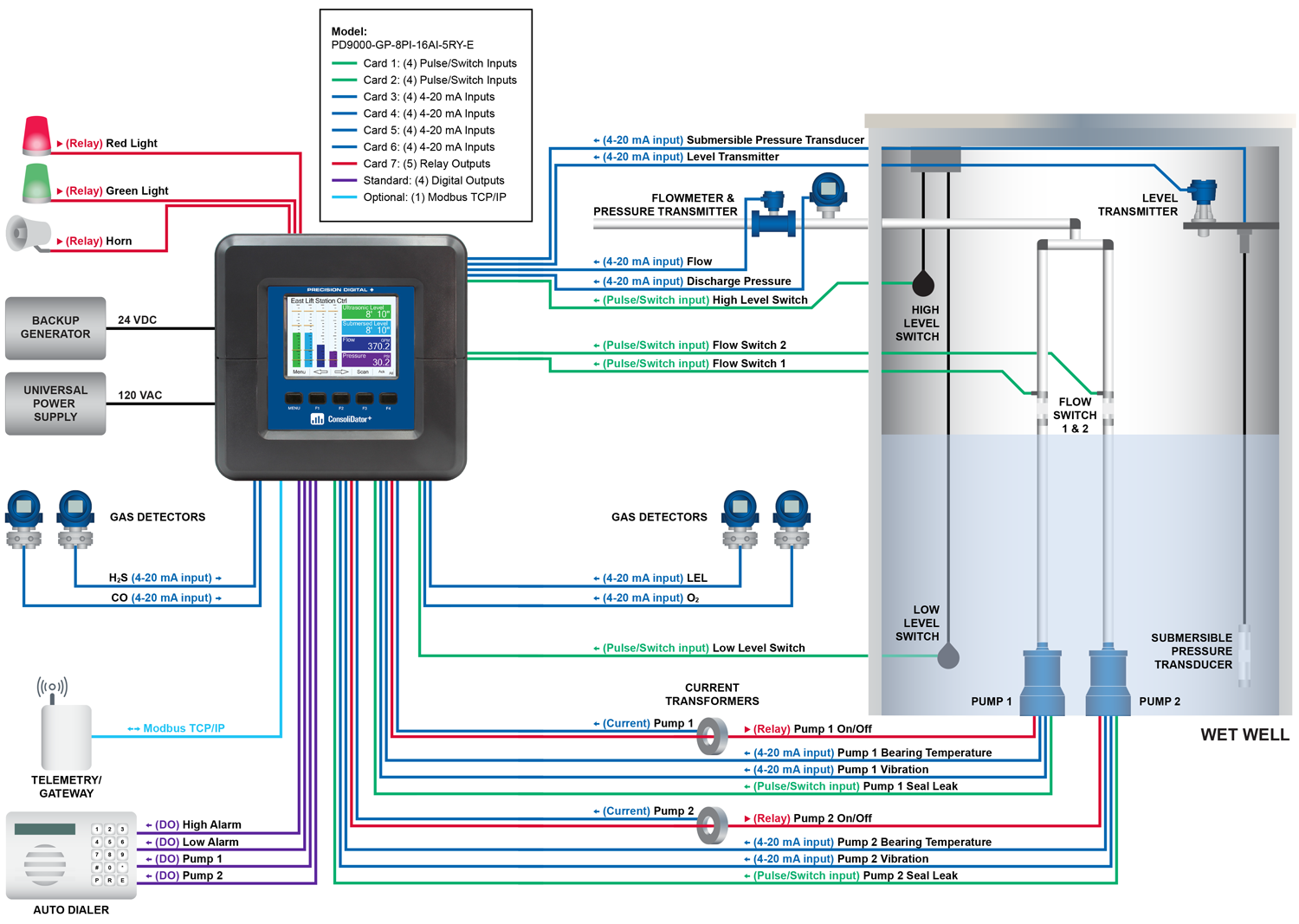

Lift stations are used to transfer waste from where it is created to where it can be treated. Multiple pumps are often used to meet capacity requirements and provide system redundancy. Multiple level technologies ensure measurement reliability during interference events. Proactively detecting maintenance issues on these pumps ensures minimal downtime. Because these sites are rarely manned, communication to a central control station and automatic alarm alerts are mandatory.

When personnel do arrive on site, they must be made aware of any hazardous gases present in the area. Flow monitoring gives the treatment plant visibility on what is coming before it arrives. All of the sensors, control logic and communication requirements for lift station operation can be consolidated into one user-friendly device, the ConsoliDator+ multivariable controller. It provides clear process visibility, simple operation and dependable reliability.

Click on diagram below to view larger

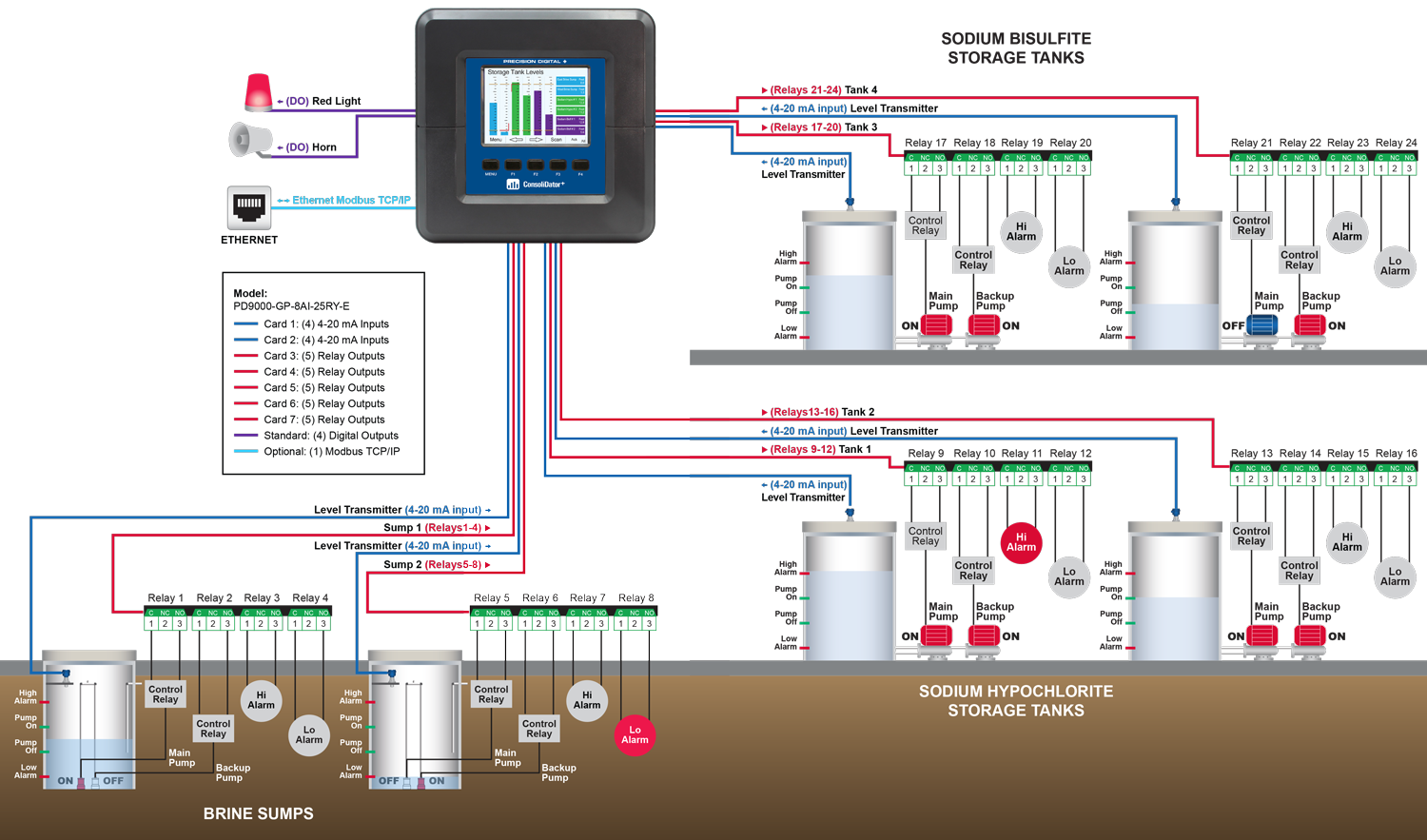

Sodium hypochlorite is a common chemical used for disinfection of wastewater after exiting sand filters. Some plants generate their own sodium hypochlorite by passing an electric current through a solution of salt and water. Sodium hypochlorite in the clean water is then neutralized before it leaves the plant by adding sodium bisulfite.

The brine, sodium hypochlorite, and sodium bisulfite are kept in sumps and storage tanks. Instrumentation is used to control the level of these chemicals and pump them from their storage tanks to the wastewater processes.

A PD9000-GP-8AI-25RY ConsoliDator+ monitors the levels and performs pump control for all these tanks and sumps. All 4-20 mA inputs from the level transmitters are isolated and powered by the ConsoliDator+. Twenty four 10 Amp SPDT relays provide high and low level alarms for each tank, and perform pump alternation for two pumps per tank. Digital outputs are used to alert plant personnel of any alarm conditions by turning on a red light and an 85 dB horn. All other data from the ConsoliDator+ is sent to the plant’s Operations Center by Ethernet Modbus TCP/IP.

Click on diagram below to view larger

Along with the ConsoliDator+ Multivariable Controller Precision Digital offers a variety of products and accessories that can be useful in a water and wastewater facility. Click on the products below to see details and pricing.